parameter group 22 Application Functions for air to volume

control calculation.

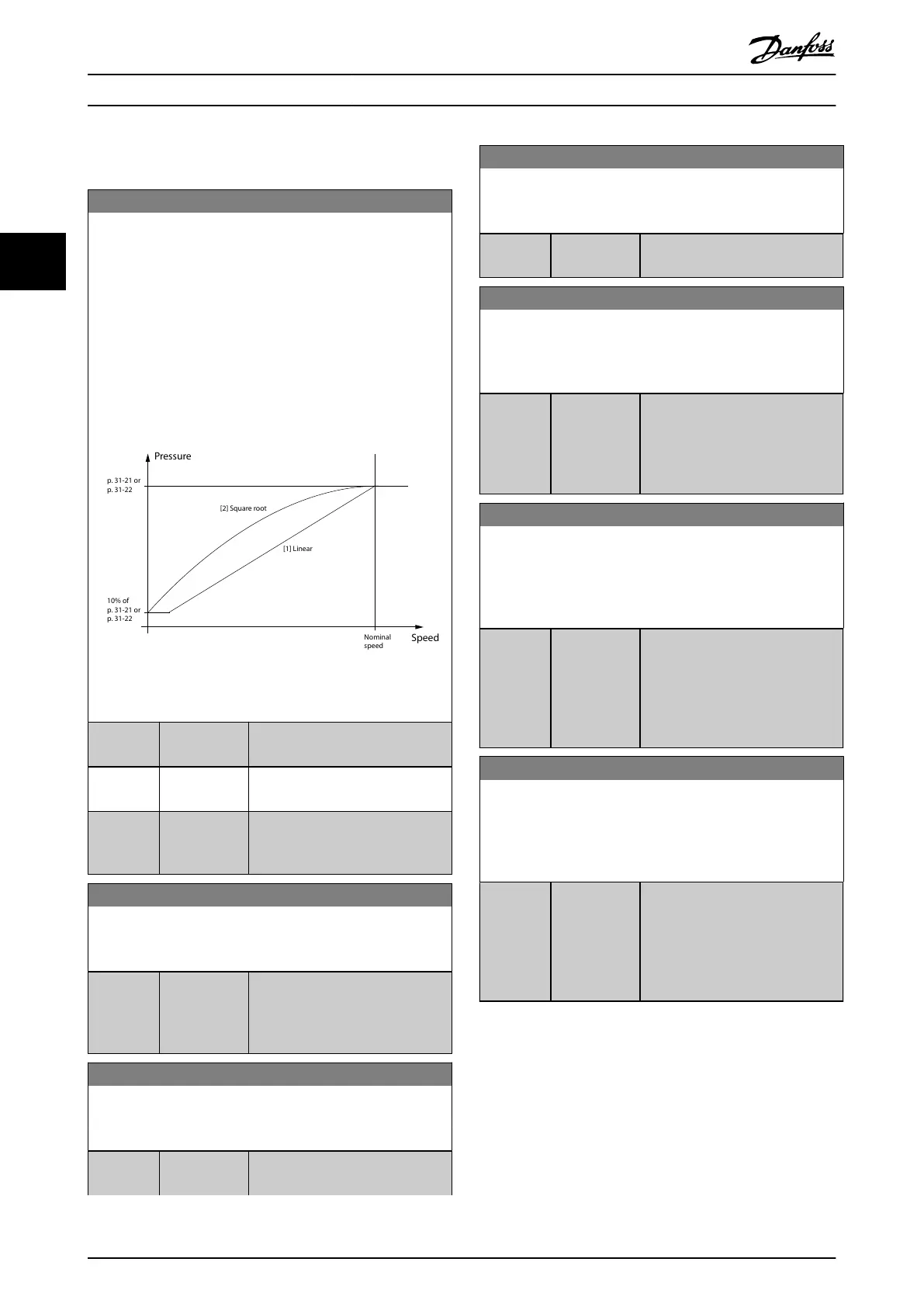

31-20 Pressure/Speed Curve Adjustment

The pressure status is based on individual thresholds levels

which are triggered when the pressure goes above or below the

threshold. The minimum and maximum values are working as

disable of the function (indicated in the LCP). The trigger levels

are dened at nominal speed operation and are adjusted to the

actual speed of the drive after dierent pressure curves. Select

the individual type of speed adjustment curve for the individual

threshold value, dened at nominal speed.

For options [1] Linear and [2] Square root, the pressure threshold

at 0 speed equals 10% of the value entered in

parameter 31-21 Below level threshold or parameter 31-22 Above

level threshold. See Illustration 3.90.

Illustration 3.90 Pressure/Speed Dependency

Option: Function:

[0] * None The pressure threshold is constant

and does not depend on speed.

[1] Linear The pressure threshold is propor-

tional to the speed.

[2] Square root The pressure threshold depends on

the speed. The dependency is

quadratic.

31-21 Below level threshold

Parameter array with 4 elements, 1 for each sensor. Default value

and value range depends on sensor version.

Range: Function:

Size

related*

[ -5000 -

5000 Pa]

Enter the lowest threshold level to

trigger pressure sensor status noti-

cations. The function is Disabled

when selecting the lowest value.

31-22 Above level threshold

Parameter array with 4 elements, 1 for each sensor. Default value

and value range depends on sensor version.

Range: Function:

Size

related*

[ -5000 -

5000 Pa]

Enter the threshold when pressure

levels exceed and notications are

31-22 Above level threshold

Parameter array with 4 elements, 1 for each sensor. Default value

and value range depends on sensor version.

Range: Function:

triggered. The function is Disabled

when selecting the highest value.

31-23 On Delay Time

Parameter array with 4 elements, 1for each sensor. An individual

On Delay time ensures that the actual conditions are active

before the status change.

Range: Function:

60 s* [0 - 3600 s] Enter the on delay time. When the

current pressure value remains

above or below the threshold after

the on delay time, notications are

triggered.

31-24 Reset Delay Time

A Reset Delay time enables an automatic reset when conditions

disappear after a certain time. The status reset can also be

managed by a local manual reset the via the LCP or eldbus

interface.

Range: Function:

9999 s* [0 - 9999 s] Enter the reset delay time, as the

time the actual value must be “o”

before resetting the status. When

entering the highest value , the

function is disabled, and a manual

reset is need via LCP or eldbus.

31-25 Pressure lter time constant

Parameter array with 4 elements, one for each sensor. A pressure

lter time constant adjusts the dynamic of the reaction to the

actual pressure input, to ensure reliable and stable status

generation.

Range: Function:

1 s* [0.01 - 60 s] Enter the pressure lter time

constant. A higher value make the

pressure signal more stable but less

dynamic. A lower value makes the

system more dynamic and allows

signal spikes to aect the control.

3.26.3 31-2** Readouts

Parameters in this group contain the actual pressure levels

and status information. The LCP can be congured to show

the values of these parameters in dierent display lines.

Use parameter 0-20 Display Line 1.1 Small to

parameter 0-24 Display Line 3 Large when conguring the

LCP to show dierent pressure values. The toggle function

allows to show multiple pressure signals in the same LCP

line. Each of the sensors can have individual customized

Parameter Descriptions

VLT

®

HVAC Drive FC 102

258 Danfoss A/S © 10/2019 All rights reserved. M0010001

33

Loading...

Loading...