Chapter 8 Logic Instructions

Programming Example

The variable table and program

Variable name Data type Initial value

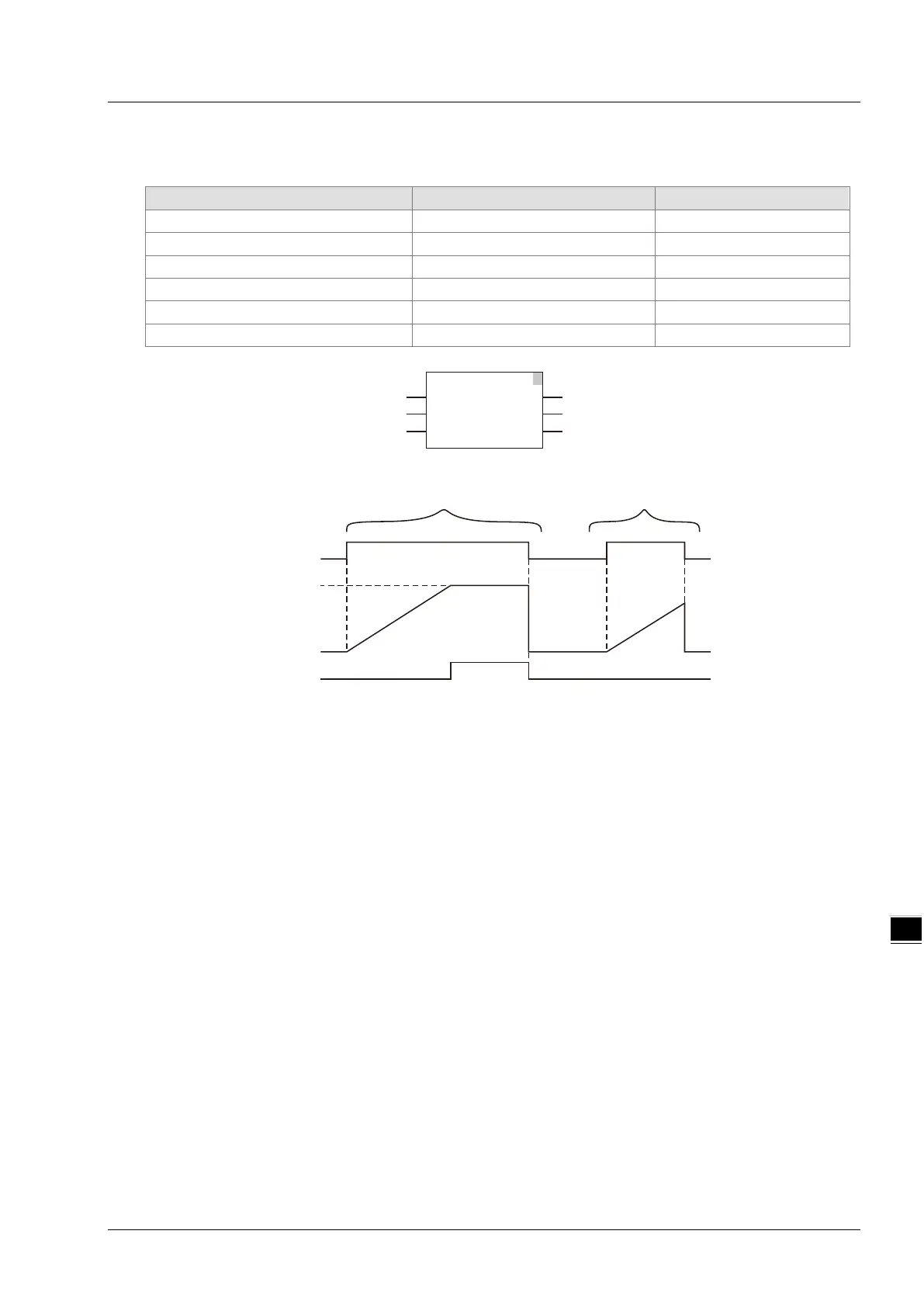

Timing Chart:

Case 1: TON1_PT is the set time. When TON1_In is TRUE, the timer starts to measure the time.

When the value of TON1_ET equals the setting value of TON1_PT, TON1_Q is TRUE.

When the timer stops measuring time, TON1_In is reset to FALSE and TON1_ET and

TON1_Q are both reset.

Case 2: When the currently measured time of the timer TON1_ET is less than the set time

TON1_PT and TON1_In is reset to FALSE, TON1_ET is reset and the state of TON1_Q

does not change.

1

TON

EN ENO

In Q

TON1

PT

TON1_EN

TON1_ In

TON1_PT

TON1_Q

ET

TON1_ET

TON1_In

TON1_ET

TON1_ Q

TON1_PT

Case 1

Case 2

8-41

Loading...

Loading...