• These models are designed to be utilized with external combiner boxes and

are not provisioned with internal DC combining capability.

• Specific size of DC conductors must be determined from NEC or other local

codes.

•

The range of conductor sizes accommodated by each DC terminal is 8~2 AWG.

• Ensure the correct conductor is connected to its associated terminal.

•

Tighten each terminal block screw to a torque value of 8AWG

-

40lbf-in (4.5N.m)

; 6~2 AWG

-

110 lbf-in (12.4 N.m).

• The bending space is 160 mm [6.3in] which meets the safety standard.

• For the 121 model, two mounting options for installing the DC connection are

available, bottom or side entry; both options have a 2" chassis access hole

(KO). Side entry is shown in Figure 3-14.

Please read the following instructions for attaching DC terminals (121 models):

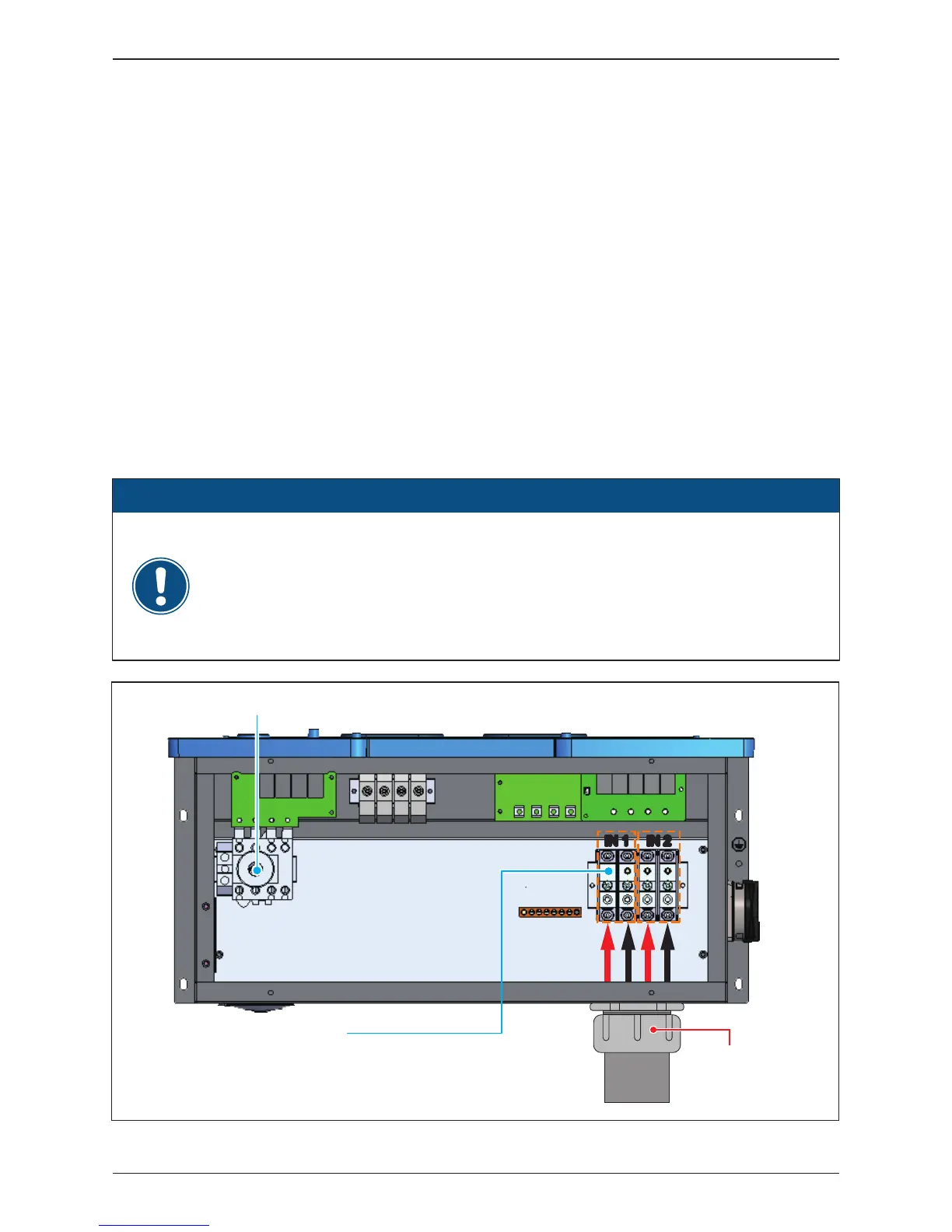

3.4.2 DC Wiring Installation for 121 models

Ensure the DC terminal block screws are tightened to a torque value of

8AWG

-

40 lbf-in (4.5 N.m)

6~2AWG

-

110 lbf-in (12.4 N.m)

- For aluminum cable :

Min./max. Conductor cross-section 10 / 33.6 mm

2

Tightening torque 110 lbf-in (12.4 N.m)

ATTENTION

Figure 3-14: Location for DC terminals for 121 models

IN 1 IN 2IN 1 IN 2

DC Terminals

Stripping length: 17mm [0.67in]

Conductor cross-section: 8~2AWG(8~33.6mm²)

Torque: 8AWG

-

40 lbf-in (4.5 N.m)

6~2AWG

-

110 lbf-in (12.4 N.m)

AC Switch

EMT

2" cable gland for

DC with EMT

39

Installation

Loading...

Loading...