3. ADJUSTMENT

Mechanical and hardware adjustments are described in this section. Software settings are

included in Section 5.2.

3.1. Mechanical settings

There are two important mechanical settings in the system:

Opto wheel setting (Vertical motor)

Sampling needle setting

The manufacturer adjusts the analyzer during production. However, in case of

repairs in the mechanical system, these adjustments should be checked. The

omission of these settings can cause malfunction or damages to the instrument.

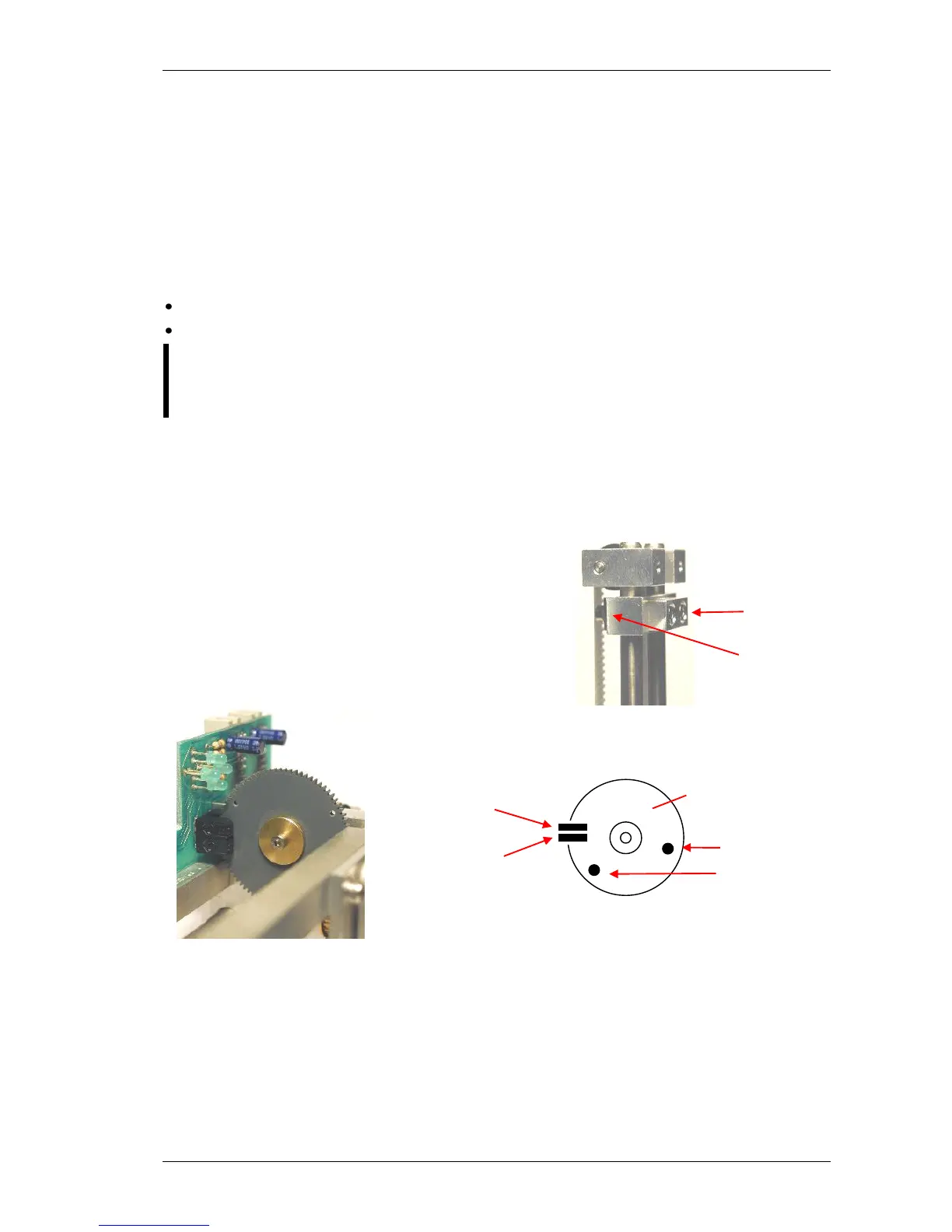

3.1.1. Opto wheel setting

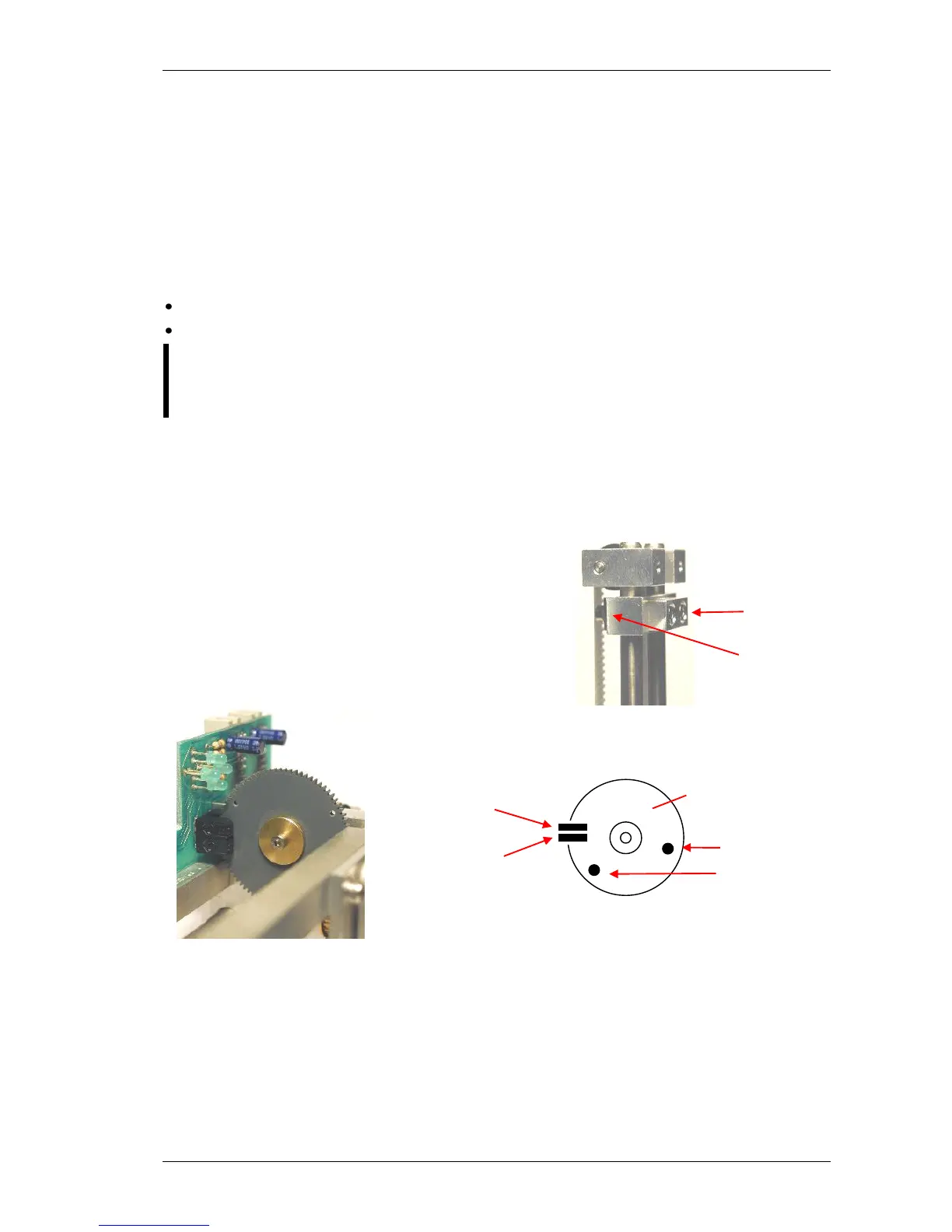

This setting is necessary for the vertical motor movements because this adjustment sets the

opto end-switches of the H&V moving unit. The top of this block is called HV head and it is

shown in the figure below.

Set the distance to 1-2 mm between the moving

carriage and the stable part of the head.

belt.

Adjust the opto wheel to home position, i.e. home hole

must be in home sensor, and LED corresponding to

home opto sensor goes on.

Check the end position as well: move the needle down. Adjustment is successful if end LED

goes on before moving part reaches end of mechanical range.

Once this adjustment is necessary, never miss sampling needle setting described in the next

section.

Loading...

Loading...