68

6. Machine Accuracy Measurement and Adjustment

6.12 Table top and Y-axis feed parallelism

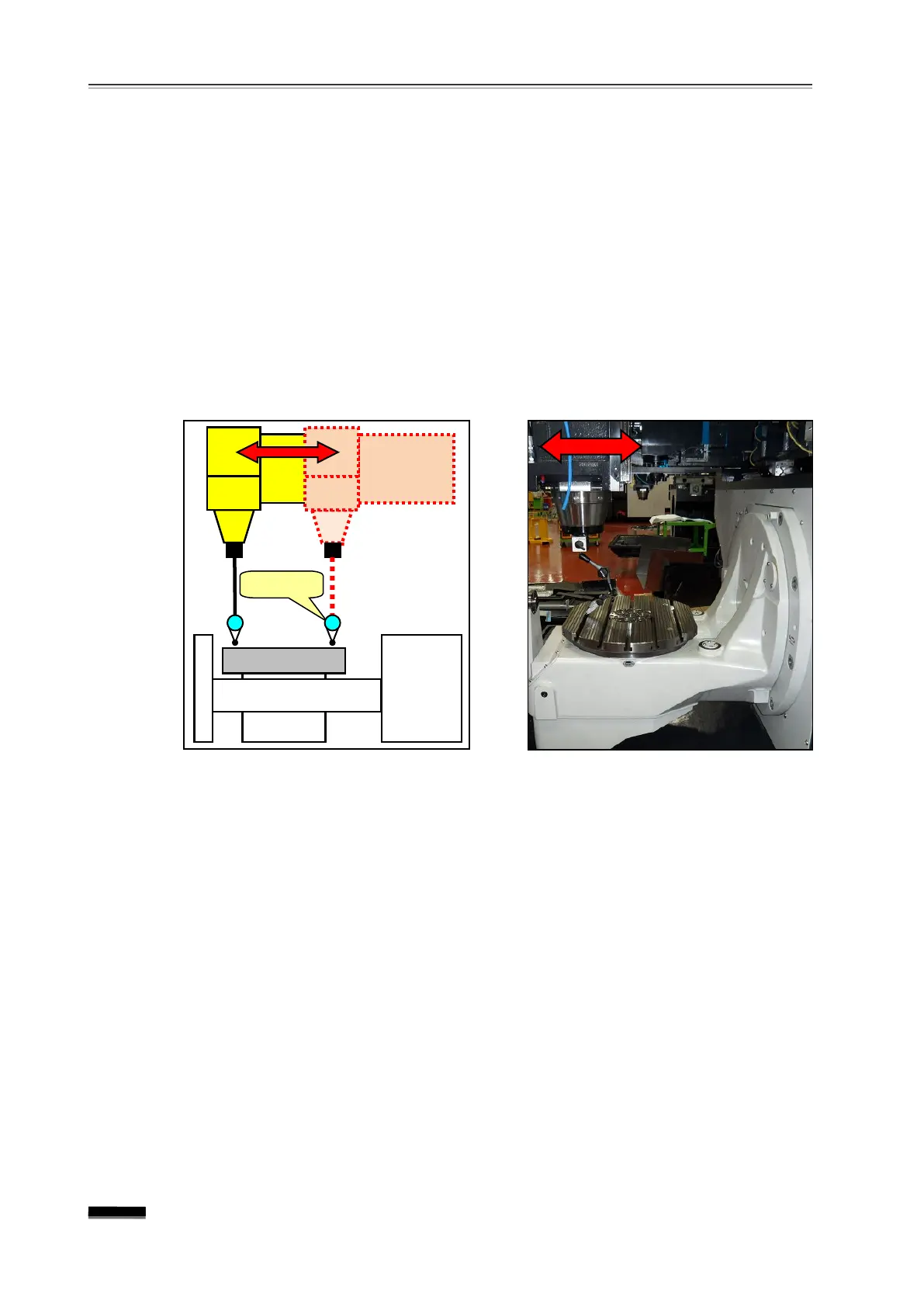

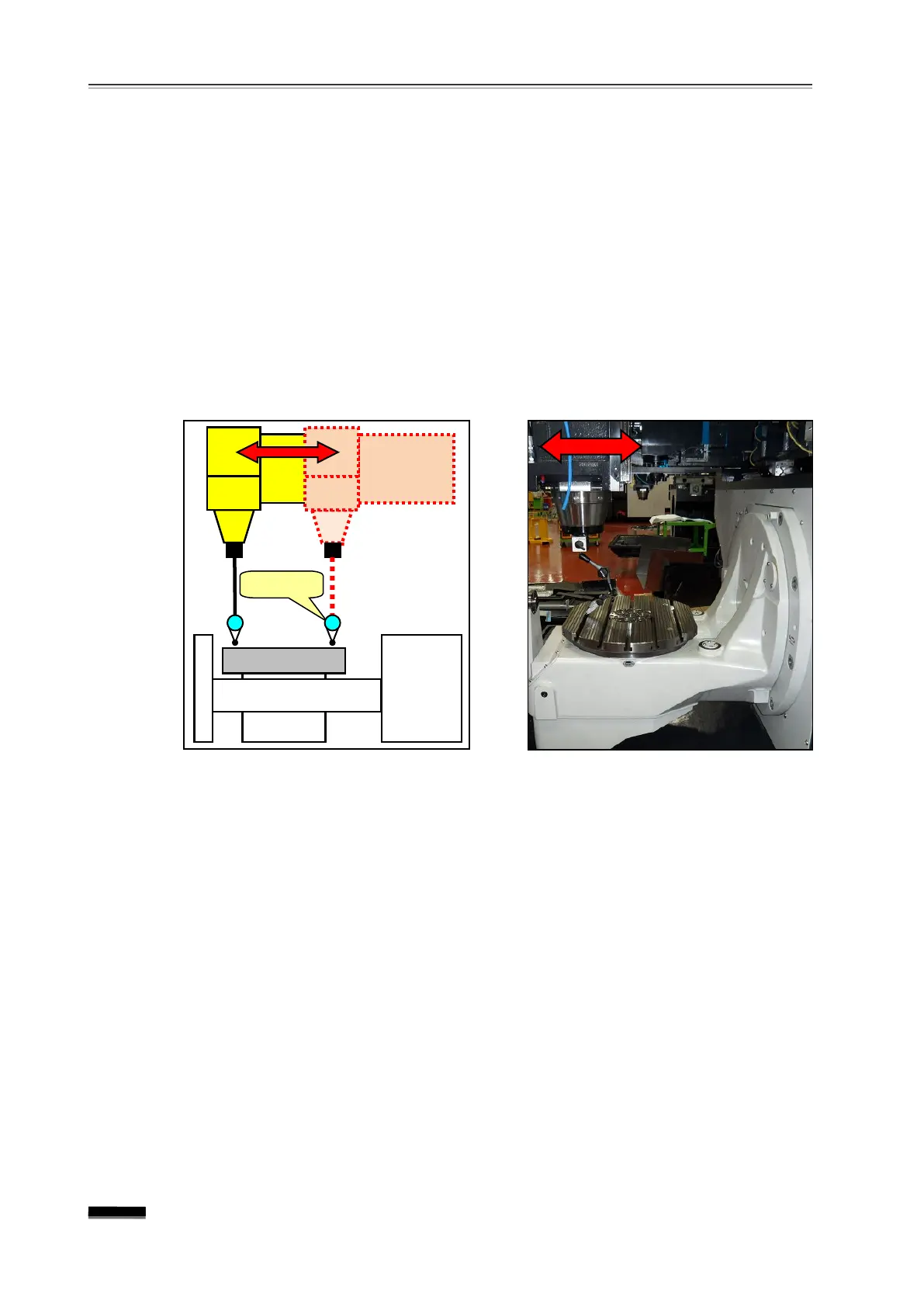

① After setting up an indicator on the spindle, transfer the T-axis to -150.

② Perform “0 ” setting on the indicator set up to the spindle at a table surface about

150mm away from the table center in the Y-axis “ -” direction.

③ Move the Y-axis about 300mm in the “+ ”

direction and measure the error amount o

the indicator.

▶ Measurement position : Height of the same table top of Y-150. and Y150. po

▶ Tolerance : 0.010mm / 300mm

Since the L/M Guide is assembled in the spindle head body, it is highly unlikely that the

table top and X-axis feed parallelism will go wrong. However, in the event of accuracy,

check the following accuracies related and review the error amount and direction before

making the necessary corrections.

① 6.10 C-axis centerline and Y-axis movement squareness

②

6.16 Table top run-out

③

6.8 Spindle centerline and Y-axis movement squareness

If there is no irregularity in

“② 6.16 Table top run-out” as mentioned above, adjust

accuracy by adjusting the Table Ass’y locking device.

Loading...

Loading...