88

7. Adjustment of reference points of respective axes and manual TCP adjustment

② Use the MPG to traverse the Z axis so that the stylus of the touch probe can be

positioned 10 to 20 mm above the datum ball.

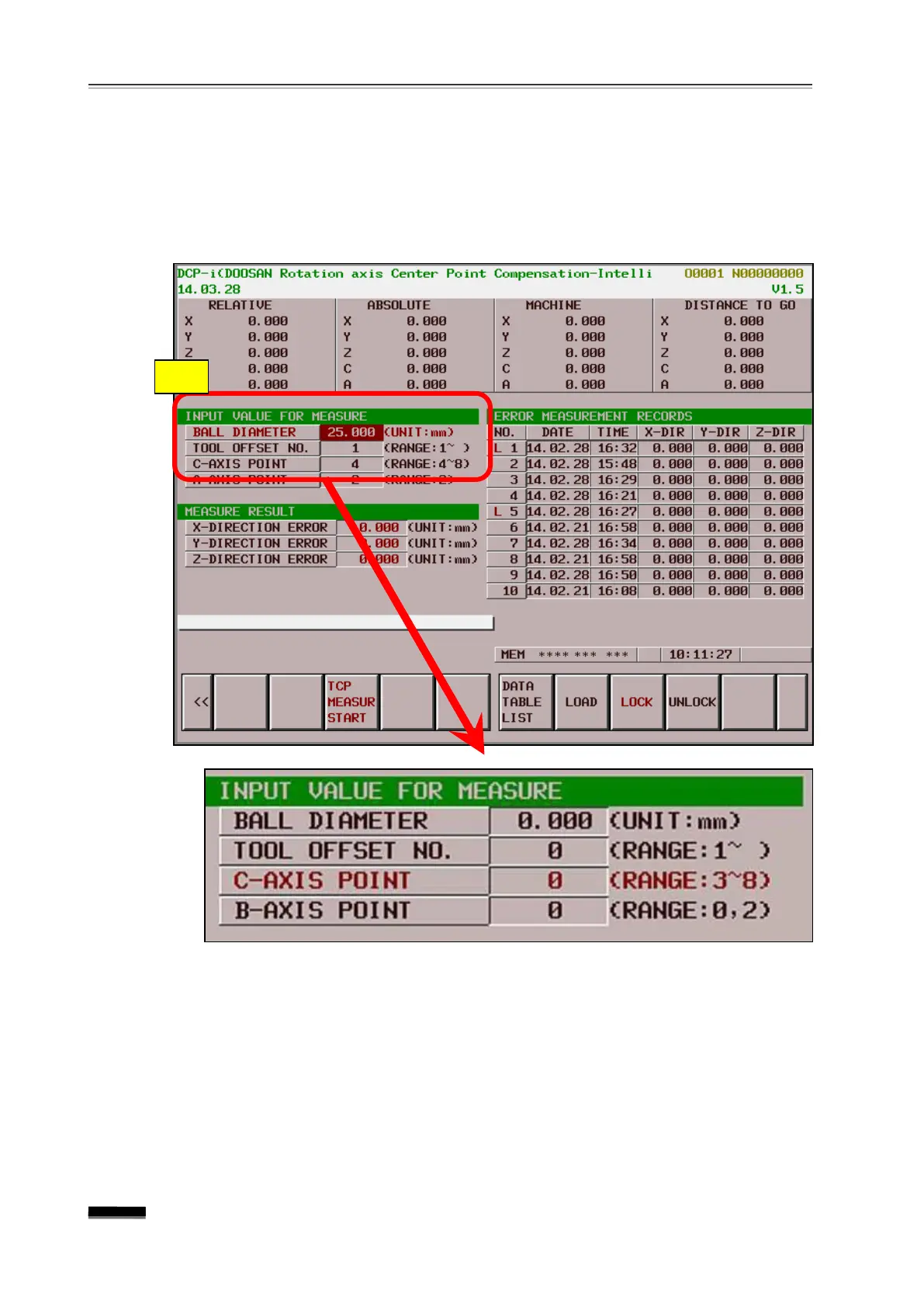

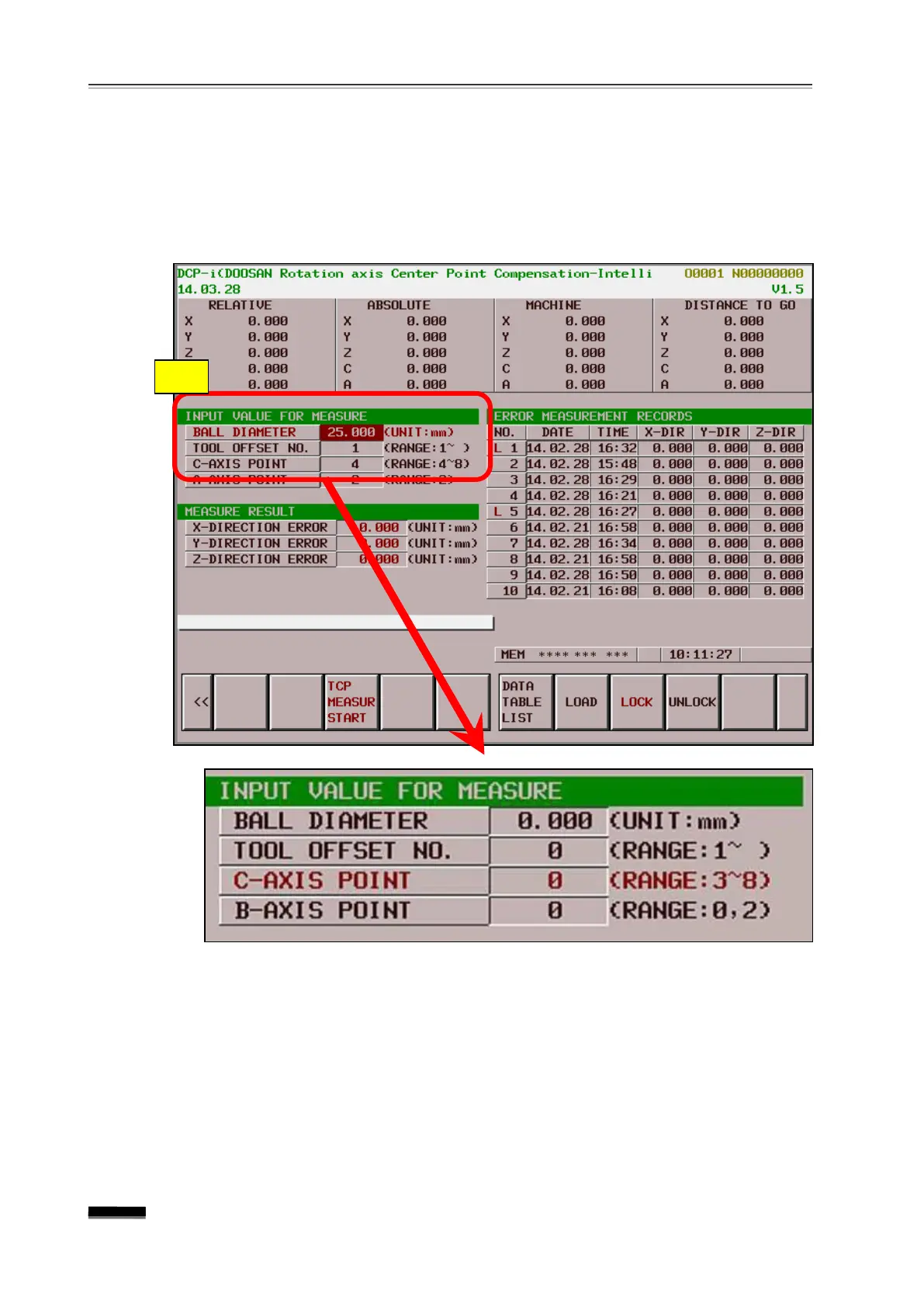

③ Enter the datum ball’s diameter, the touch probe’s tool offset number, the C axis

measurement number, and the B axis measurement number in the figure area (“B”)

below.

① BALL DIAMETER : Enter the diameter of the Datum Ball.

② TOOL OFFSET No. : Enter the tool offset number of the Touch Probe.

③ C-AXIS POINT : Enter the number of times of C-axis measurement.

(Recommended value = 4)

④ A-AXIS POINT : Enter the number of times of B-axis measurement.

(Recommended value = 2)

“

”

Loading...

Loading...