38

Accessories

Mounting:

● Remove status display PIR 7000/7200,

flow cell PIR 7000/ 7200 or remote test

adapter PIR 7000/7200 from gas

transmitter.

Remove joint seal ring PIR 7000 if

applicable.

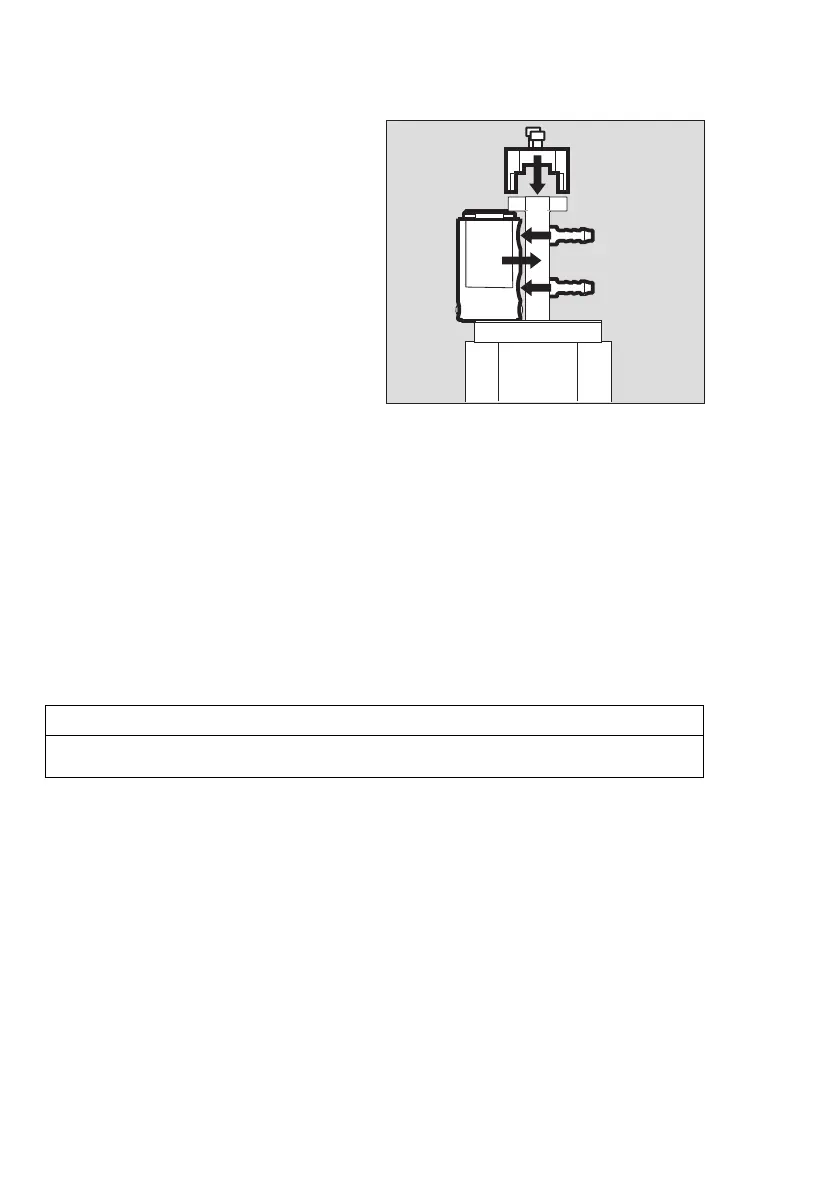

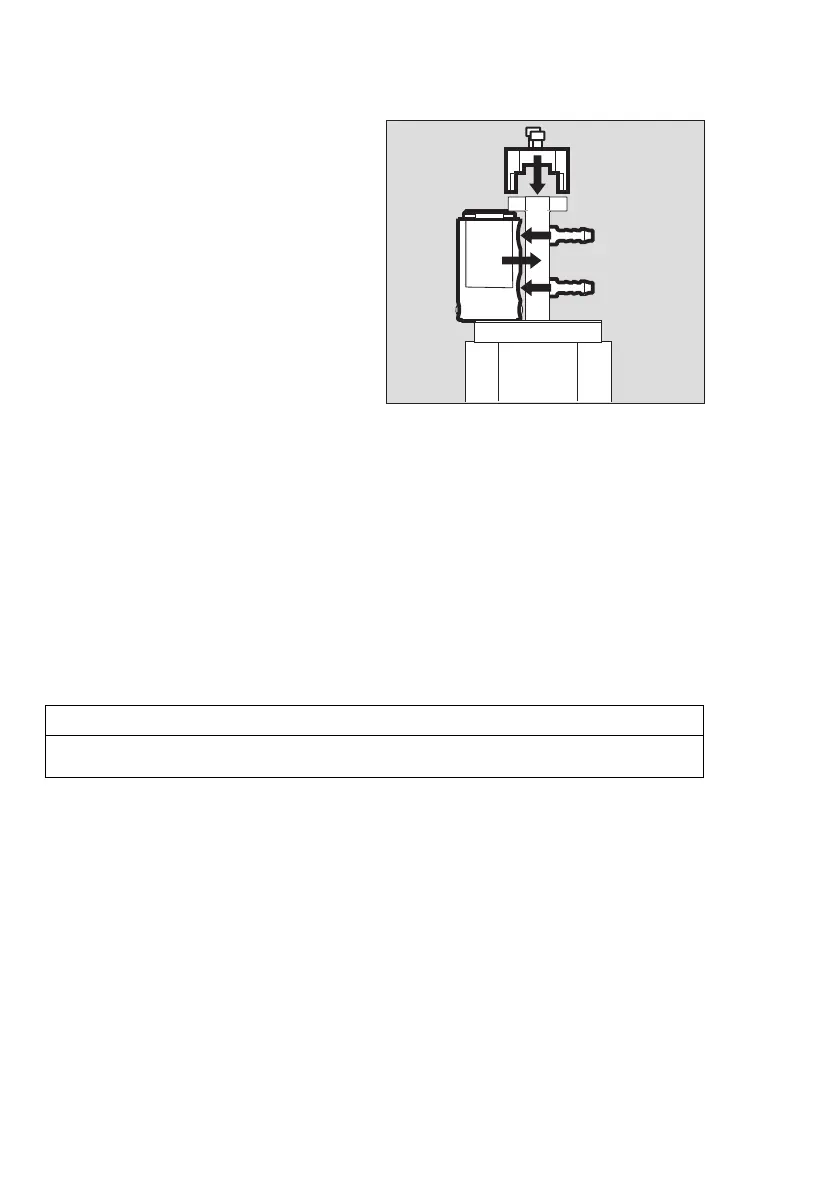

1 Carefully insert process cuvette between

the two ridges of the gas transmitter.

Make sure that the sealing ring is fitted

between process cuvette and gas

transmitter. Ensure that the seals and

sealing surfaces are tightly fitted and

clean.

2 Fit holder to the gas transmitter and

fasten using two screws.

3 Screw on connecting bushes.

● Connect gas lines to the connecting bushes. During this process, ensure in particular that

the material is compatible with the substance to be monitored.

The gas inlet and gas outlet connection can be freely selected.

● Check system for sufficient gas-tightness.

— The response time is dependent on the set volume flow (see "Performance Characteristics

(typical values)" on page 73).

NOTICE

After each installation or removal of the process cuvette, it is absolutely necessary to

calibrate the zero point and sensitivity!

Operating notes

The display of the Dräger PIR 7000/Dräger PIR 7200 depends on the partial pressure of the

measured gas component. Alternating gas pressures or gas pressures which differ from the

atmospheric pressure may be created in the process adapter due to system-related

parameters such as flow rates, nominal diameters of inlets etc.

The maximum allowed internal pressure is 3000 mbar,

the minimum allowed internal pressure is 700 mbar.

01123886_01.eps02323886_01.eps

1

2

3

3

Loading...

Loading...