55

Maintenance

Example: If the gas transmitter Dräger PIR 7000 has been calibrated under normal air

pressure (1013 mbar), a pressure change to 900 mbar would result in the following change of

the measuring value:

(Remedy: Applying 50 %LEL calibration gas at 900 mbar pressure)

Preparing Calibration

● Provide calibration gas.

For gas transmitters with mounted splash guard PIR 7000 / 7200:

● Push calibration adapter PIR 7000 onto the splash guard until it locks into place.

For gas transmitters with mounted flowcell PIR 7000 / 7200, bump test adapter PIR 7000 /

7200, process adapter PIR 7000 or process cuvette PIR 7000:

● Connect calibration gas feed directly to the flowcell, the bump test adapter, the process

adapter or the process cuvette.

Calibration Using the Magnetic Wand

The calibration can be performed directly at the gas transmitter using the magnetic wand (part

no. 45 43 428).

50 %LEL X

900 mbar

= 44 %LEL

1013 mbar

NOTICE

When delivered, the gas transmitter is calibrated with a reference pressure of 1013 mbar.

Deviations from this reference pressure can lead to deviating measured values at any

concentration.

CAUTION

Always first calibrate the zero-point before the sensitivity (span).

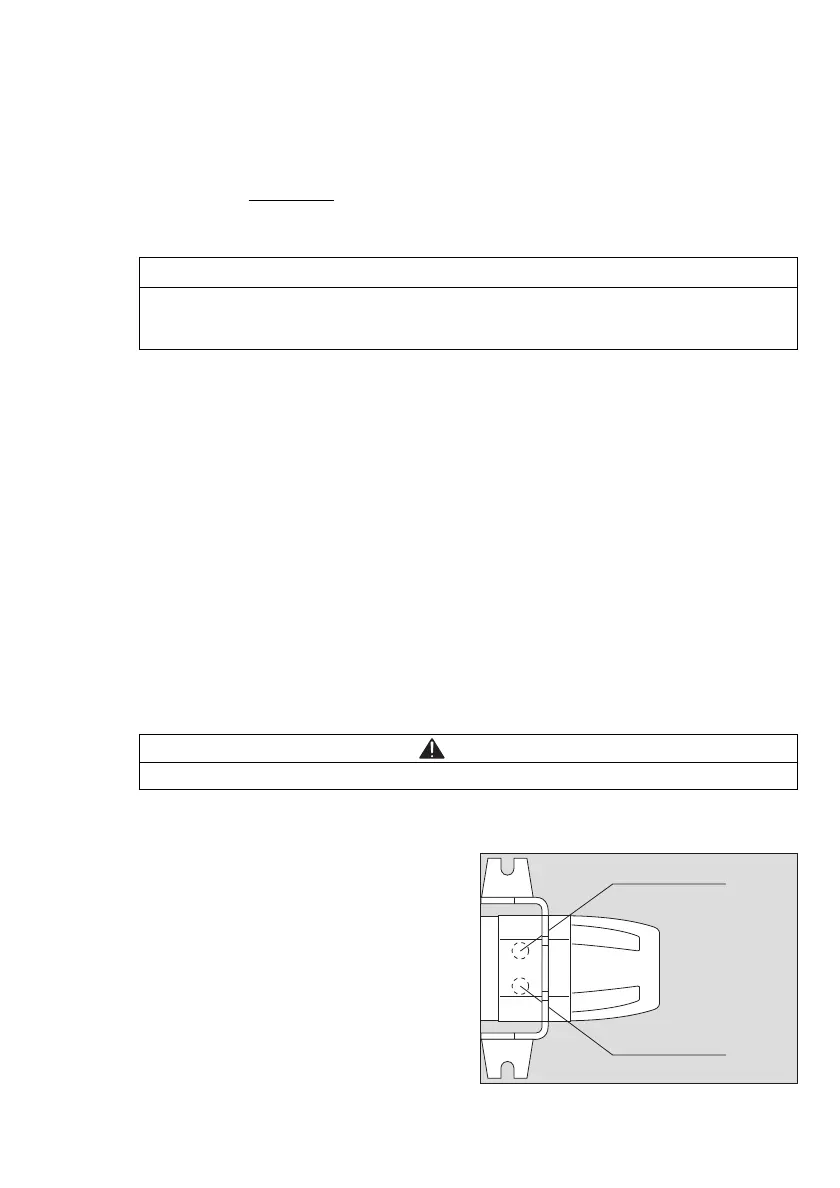

Calibration using the magnetic wand:

— The gas transmitter has the marks on two

opposite sides; » 0 « for "Zero-point" and

» S « for "Sensitivity (span)".

● For calibration, place the magnetic wand

onto the respective mark.

03023886_01.eps

S

0

Loading...

Loading...