04/10 MN04020001Z-EN

Parameter menu (PAR)

103

When P5.1 (2.3) = 25, you can set the digital output or a

signalling relay for the FBV.

The FBV actual value message enables the PID controller of the M-

Max

TM

to implement a direct “two-stage control”, as is commonly

used for HVAC applications.

Example: ventilation system with two fans (frequency inverter).

Under normal operating conditions, the maximum output power

of fan 1 (M1) is sufficient to maintain the actual value (PV) at the

reference value. When fan 1 is fully utilized and additional airflow

is required, a second fan (M2) with constant power is a simple

solution.

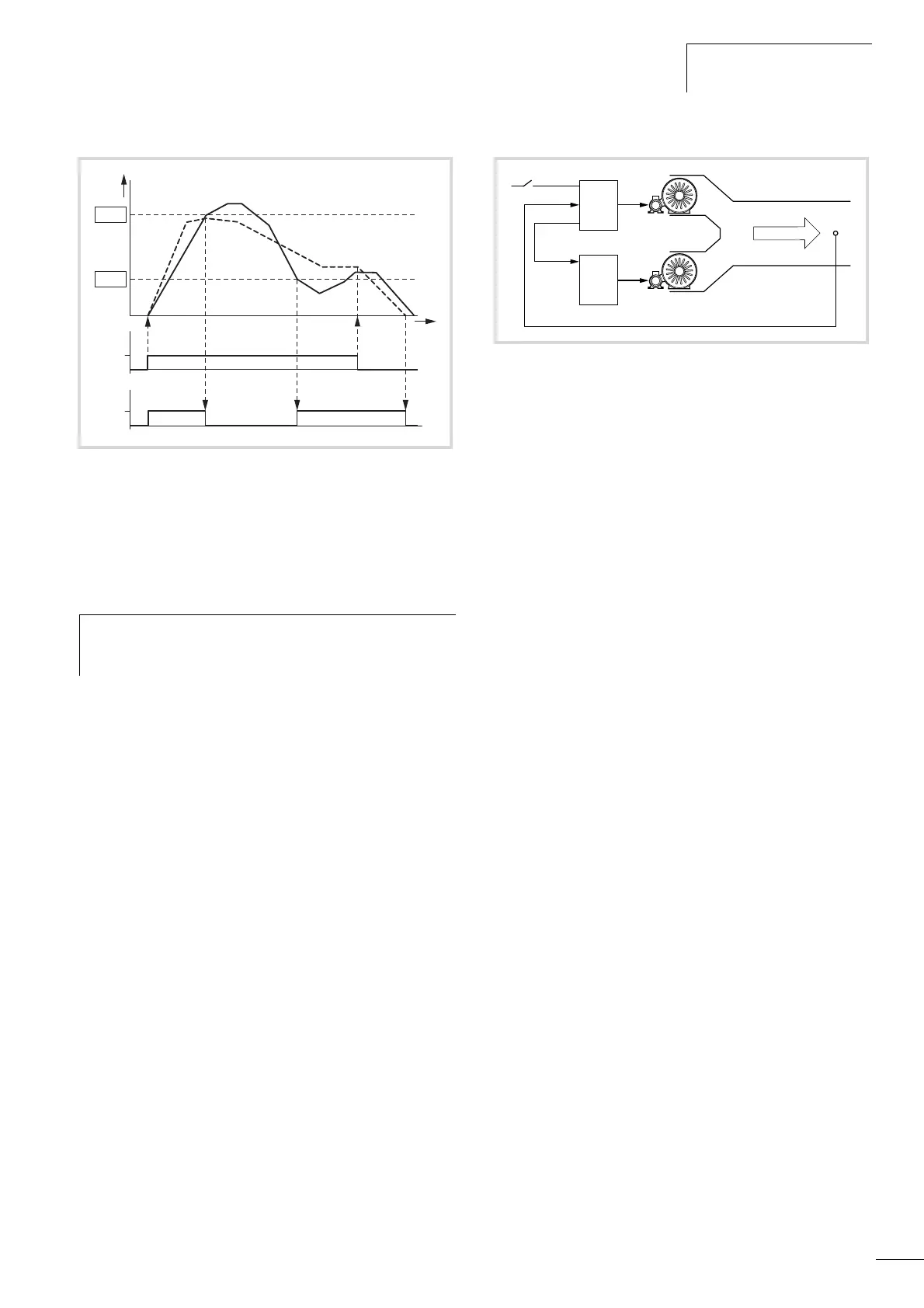

With the closed-loop control example shown here, the sequence is

based on the signal diagram in Fig. 90 The process variables in the

limit values are shown in percent (%). The output frequency (Hz)

is shown superimposed in the same diagram.

• Start of fan motor M1 with FWD signal. The actual value (PV) is

below the limit value of P9.16. The FBV output (P5.1 (23 = 25))

then switches and fan motor M2 (Start) starts automatically.

• The actual value rises and reaches the upper limit (P9.15). The

FBV output is automatically switched off (= fan M2 Off).

Fan M1 remains in operation and works in linear control mode.

In a correctly set up system, this is the normal operating range.

• If the actual value drops below the limit value (P9.16), the FBV

output is switched. and fan M2 is activated again to support fan

M1.

• When the FWD signal is removed from frequency inverter 1, the

inverter goes from RUN to STOP mode and decelerates the drive

over the set ramp time.

• When frequency inverter 1 is stopped, the FBV output is

automatically de-energized so that fan M2 also stops.

Figure 90: PID controller, actual value message FBV

a Output frequency [Hz].

b Actual value (process variable PV).

FWD: Start signal, clockwise rotating field.

FBV: Actual value message, limit values exceeded (P9.15,

P9.16).

h

The upper and lower actual value limits (P9.15, P9.16) are

“process messages”. They cannot be used for monitoring

the actual value signal. FBV is not a fault message.

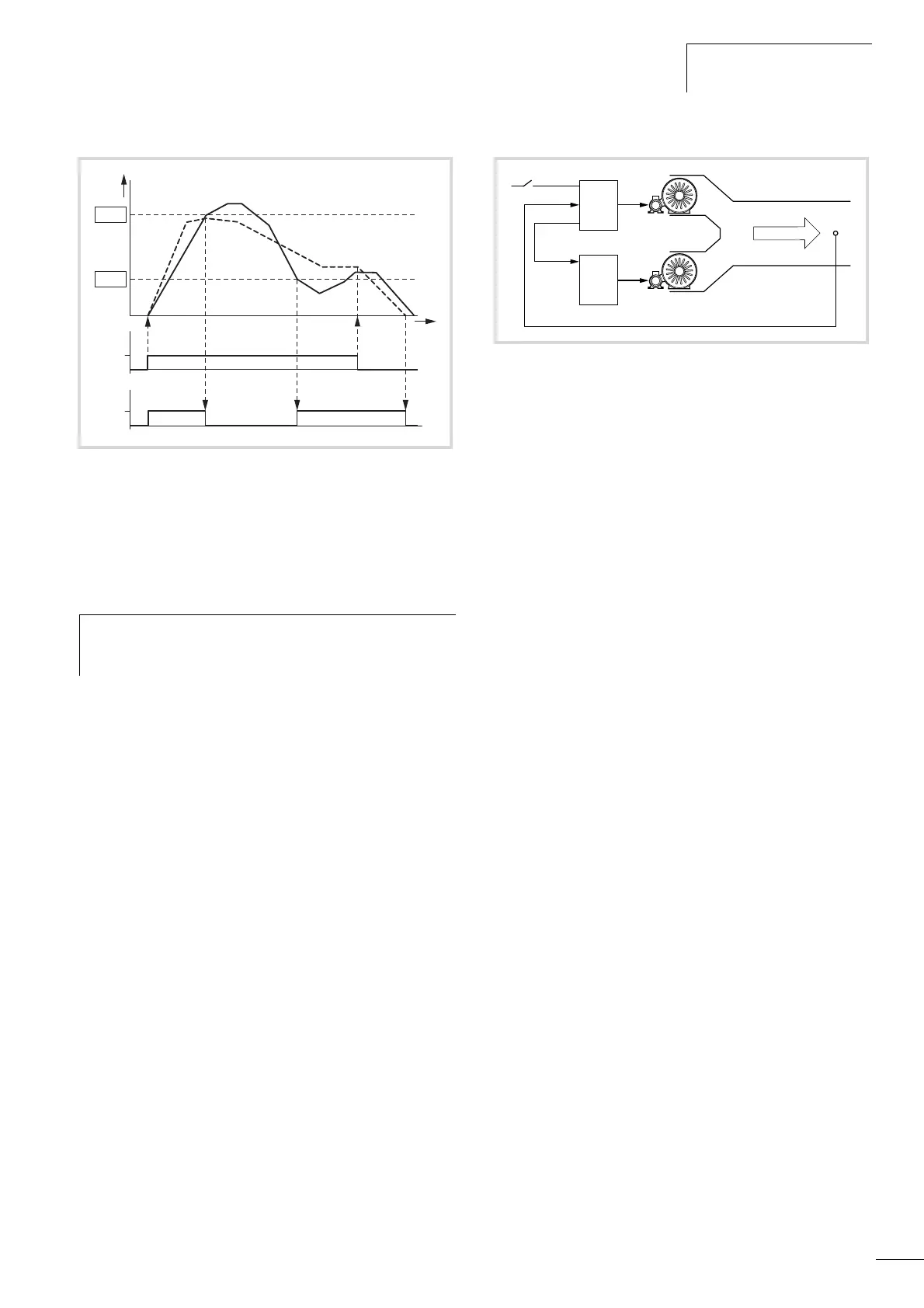

Figure 91: Block diagram, ventilation with “two-stage control”

1: Frequency inverter with PID controller for fan motor M1.

2: Motor starter (frequency inverter, soft starter, contactor) for

fan motor M2.

FWD: Start signal drive 1.

FBV: Actual value message of drive 1 for activating drive 2.

PV: Process variable (air volume m

3

/h) as normalized actual

value.

Start: Start signal, drive 2.

PV

1

2

FWD

M2

M1

FBV

Start

0... 10 V/ 4... 20 mA

Loading...

Loading...