The nEXT pump is supplied with an inlet screen. The inlet screen is installed in the

cent

ering O-ring for ISO version pumps and in the envelope for CF version pumps. The

nEXT pumps with an NW25 interstage port are supplied with an inlet strainer. The inlet

strainer is installed in the interstage port. The inlet screen and inlet strainer prevent the

damage to the pump caused by debris entering the pump.

The nEXT pump has a vent port for venng the pump and vacuum system to the

atmospheric pressure. The pump has a manual vent valve which can be replaced with a

TAV5 or TAV6 solenoid‑operated vent valve (available as an accessory, refer to

Accessories on page 99). The on‑board motor controller can control the TAV valve.

The nEXT pump has a purge port through which an inert purge gas can be introduced to

protect the bearing and motor from corrosion. You can install an oponal vent port

adapter and purge restrictor to the purge port to control the ow rate of the purge gas

and to lter the gas supply. Refer to Accessories on page 99.

Air coolers and a water‑cooling block are available as an oponal accessory to cool the

nEXT pumps. Refer to Accessories on page 99.

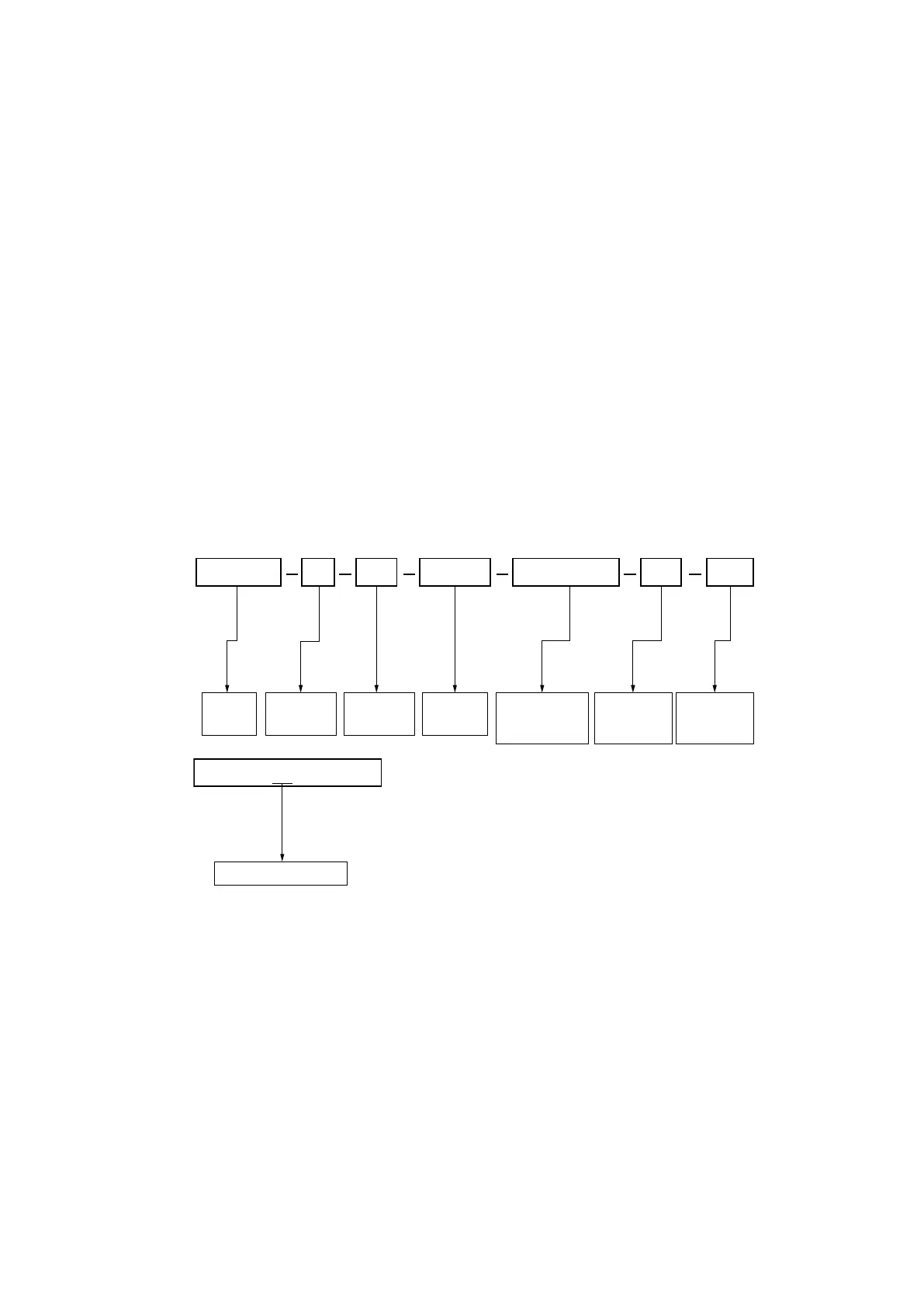

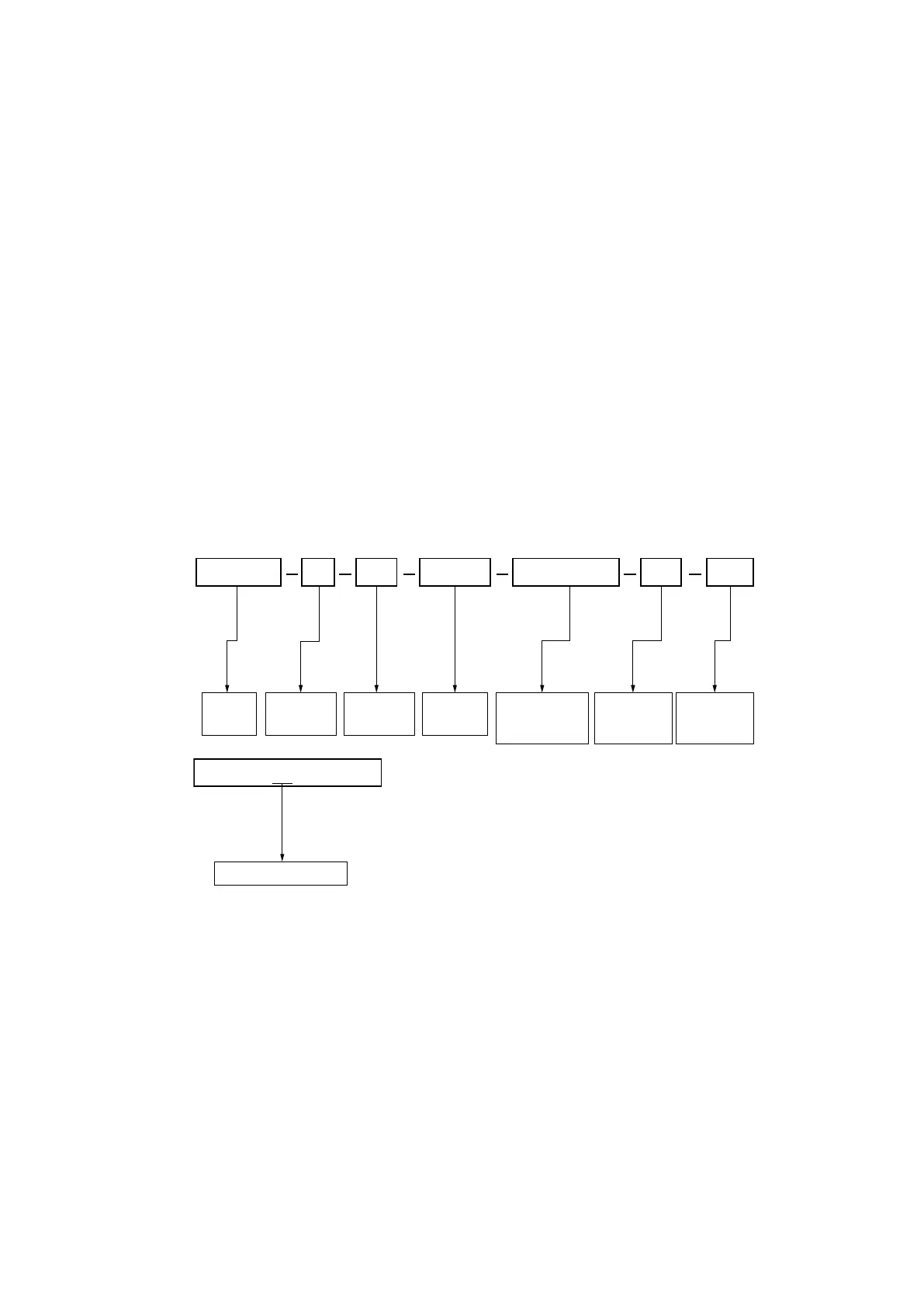

2.2 Pump model descripon

Figure 1 Pump model descripon

NEXT240

SERIAL : YYXXXXXXX

Pump

type

I DL ISO100 NW25/25 105 FPS1

Interstage

Variant

Mechanism

type

Envelope

type

Backing port /

Default

power

setting

interstage port

type

Customer

variant

Year of manufacture

2.3 Pump controller

The pump con

troller has the drive electronics that control the pump operaon and the

TAV vent valve. The connector socket is given at the side of the controller where the

TAV vent valve can be plugged in. Refer to Controller connector socket on page 34.

The controller has three indicator LED's which signal the general status, operaon and

the service status of the pump. The LEDs can be used for fault nding if a problem

occurs. Refer to Indicator LED's on page 35.

The drive electronics system has a number of built‑in safety features to prevent

the pump from damage during sustained high pressure or temperature.

▪ The electronics constantly monitors the temperature in the controller and the

temper

ature of the motor in the pump. If the controller or the motor gets too hot,

04/2022 - ©Edwards Limited

Page 12B80000880_G

B80000880_G - Introducon

Loading...

Loading...