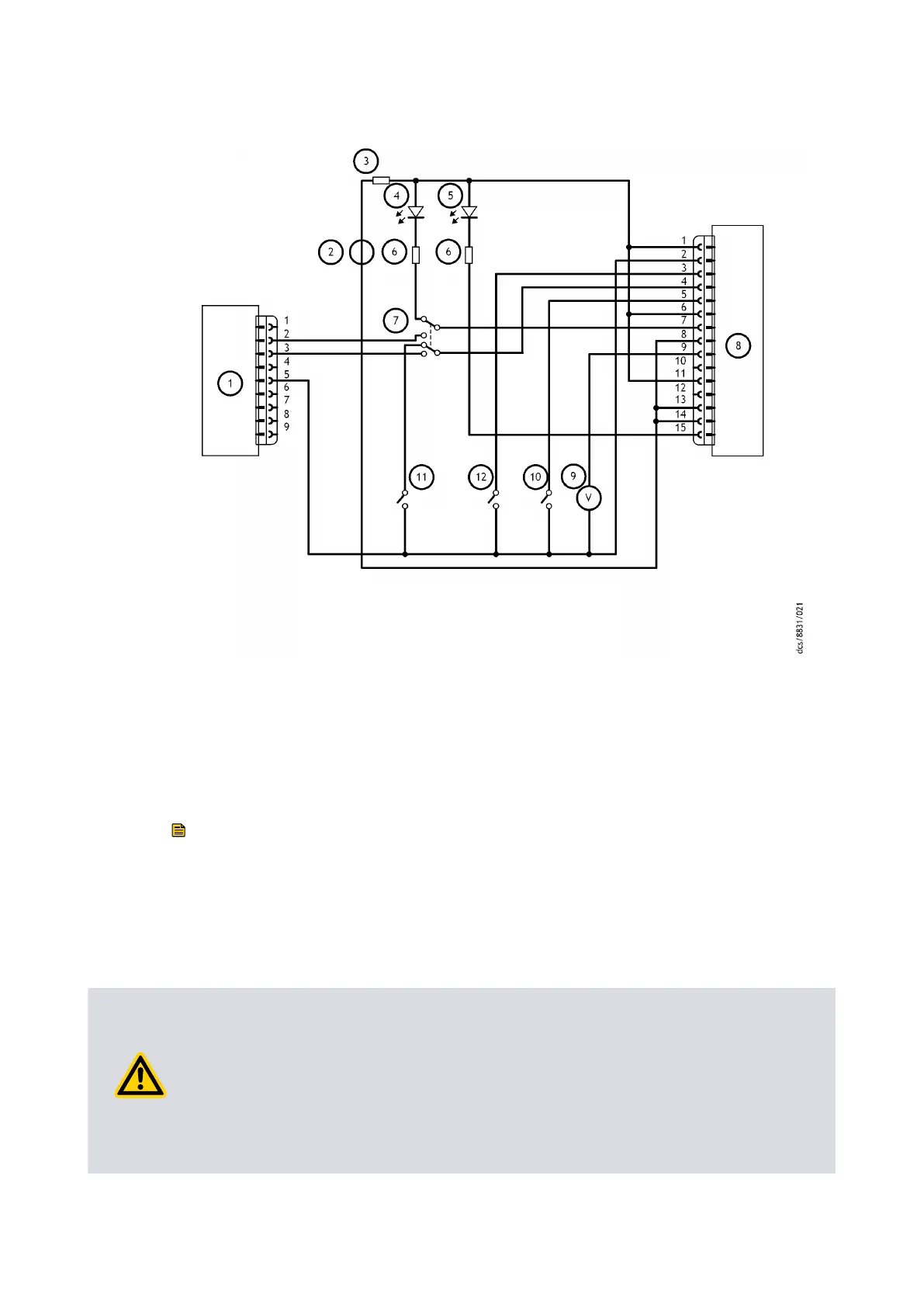

Figure 19 Logic interface connecon - mix

ed parallel and serial operaon

1. RS232 interface on control equipment 2. 24 V d.c. electrical supply

3. Fuse 4. Oponal LED indicat

or ‑ system OK

5. Oponal LED indicator ‑ normal speed 6. Current limit resistor for LED

7. Oponal serial link selector 8. pump

9. Oponal voltmeter 10. Oponal serial enable switch

11. Oponal standby switch 12. Start switch

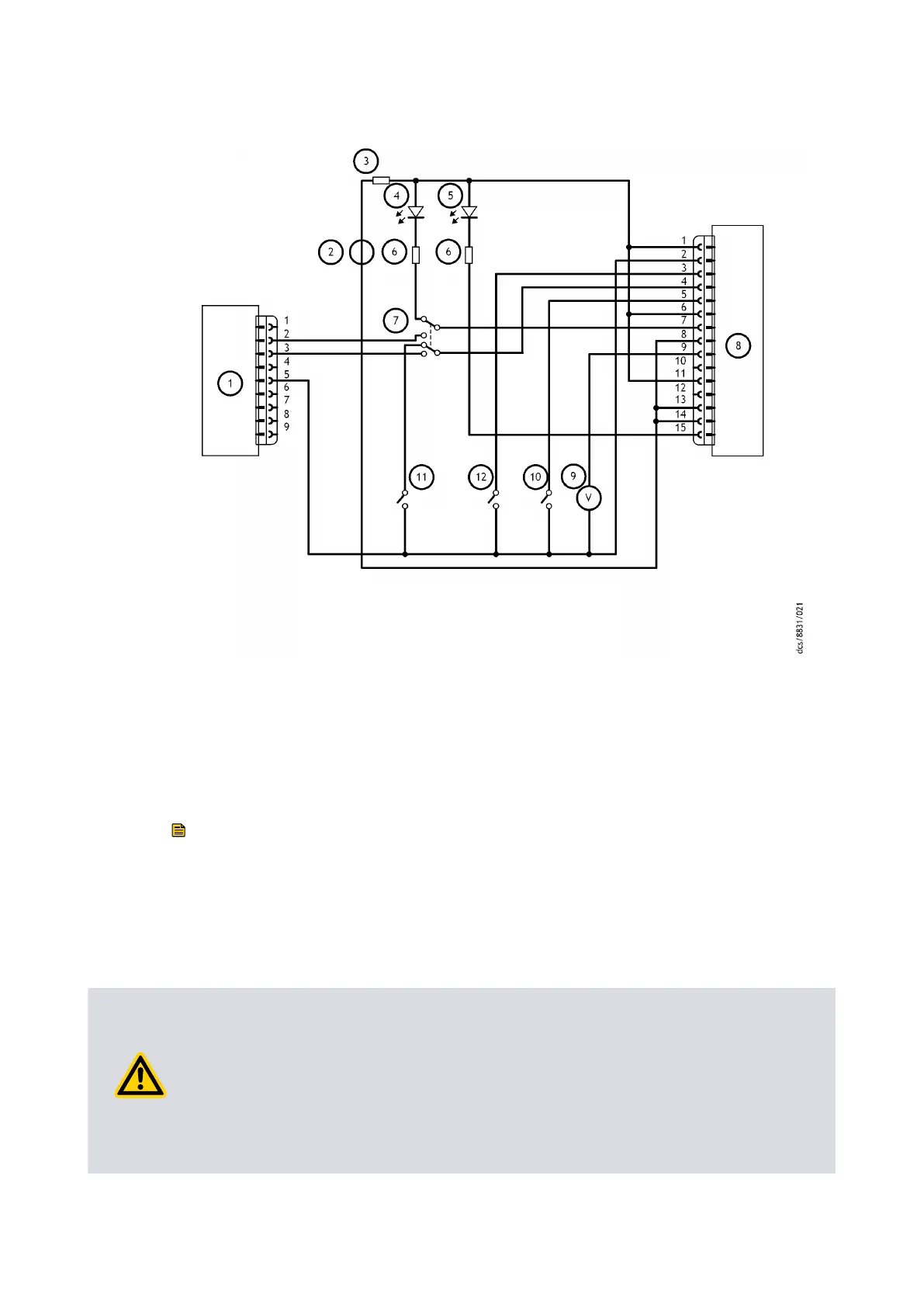

1. RS232 interface on control equipment 2. 24 V d.c. electrical supply

3. Fuse 4. Oponal LED indicator ‑ system OK

5. Oponal LED indicator ‑ normal speed 6. Current limit resistor for LED

7. Oponal serial link selector 8. pump

9. Oponal voltmeter 10. Oponal serial enable switch

11. Oponal standby switch 12. Start switch

Note:

The volt

age supply to the pump controller can be more than 24 V. But the circuits

connected to the normal and fail line must have maximum external pull‑up voltage

rang as given in Table: Logic interface technical data.

4.9 Vent opons, vent valve connecon and control

CAUTION: RATE OF INCREASE IN PRESSURE

Risk of damage t

o equipment. If you vent the pump when it is at full rotaonal speed

and the rate of increase in pressure is too high, the pump can get damaged and its life

can decrease. We recommend to limit the rate of increase in pressure (refer to Figure:

Maximum allowed rate of increase in pressure during venng: pressure against me

(pump inially at full speed)) or open the vent valve only aer the pump speed has

decreased to 50% of the full rotaonal speed.

04/2022 - ©Edwards Limited

Page 57B80000880_G

B80000880_G - Inst

allaon

Loading...

Loading...