4.3.3 Inlet connecon and orien

taon

The pump can be installed at the vacuum system through the inlet ange. You can

mount the pump in vercal and upright through to horizontal (± 2°). If the pump is

mounted horizontally and used with a rotary vane backing pump, make sure that a

foreline trap is installed to prevent the condensed oil in the backing line from entering in

the turbo pump. If installaon of the foreline trap is not possible, install the pump with

the backing port that points vercally down (± 45°).

Note:

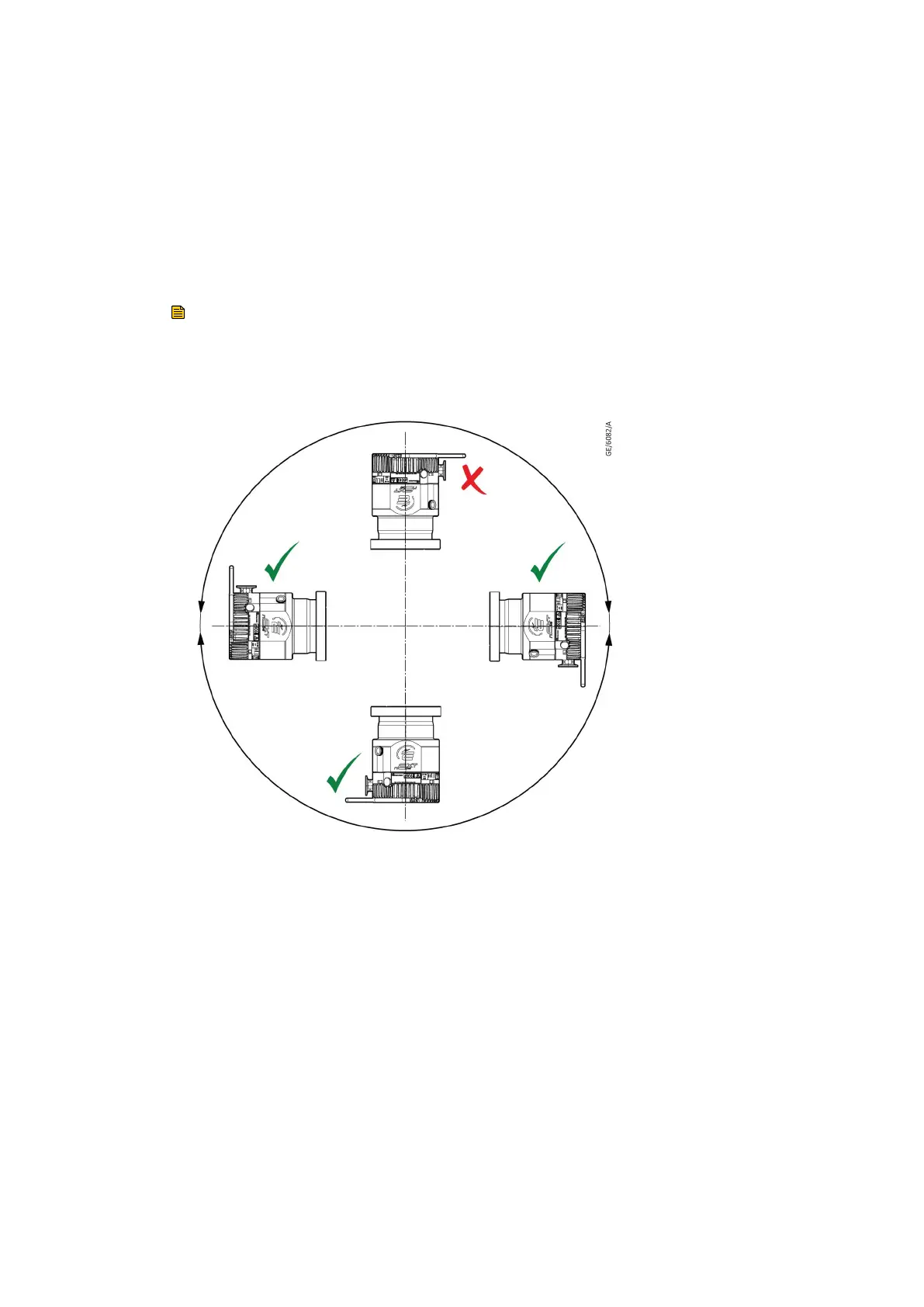

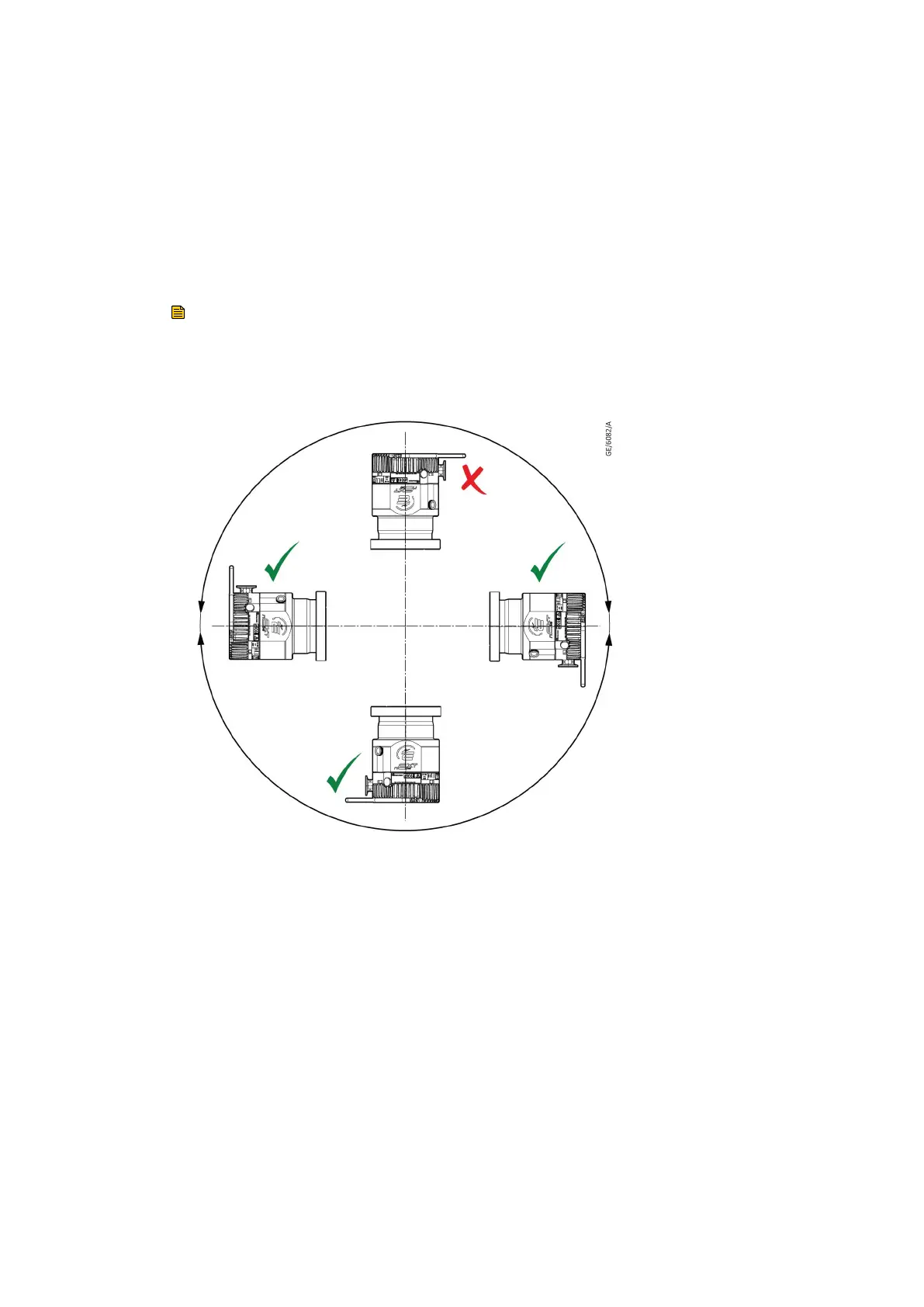

Do not operate the pump in in

verted posion. Refer to Figure: Installaon orientaon.

Figure 12 Installaon orientaon

Make sure that the pump inlet and the components installed to the pump inlet are clean

and dust‑

free. Failure to do so can increase the pump‑down me.

The inlet connecons for the pump are CF ange, ISO ange and VG ange.

▪ If the pump has a CF ange, use the copper compression gasket supplied with the

pump. Use all supplied bolts to connect the inlet ange of the pump to the

vacuum system.

▪ If the pump has an ISO ange, use the manufacturer's combinaon inlet

screen / trapped O‑ring supplied with the pump. Use minimum four claw clamps

(each torqued to 30 Nm) to connect the inlet ange of the pump to the vacuum

system.

You can also use a rotatable collar and the combinaon inlet screen and trapped

O‑ring supplied with the pump to connect the inlet ange of the pump to the

vacuum system. Use all supplied bolts with the rotatable collar.

▪ If the pump has a VG ange, use all supplied bolts of 8 x M10 and w

ashers to

connect the pump to the vacuum system. Flange installaon bolts must have

04/2022 - ©Edwards Limited

Page 41B80000880_G

B80000880_G - Inst

allaon

Loading...

Loading...