Refer to Table: Logic interface connector pins when y

ou connect the electrical supply to

the customer connector mang half.

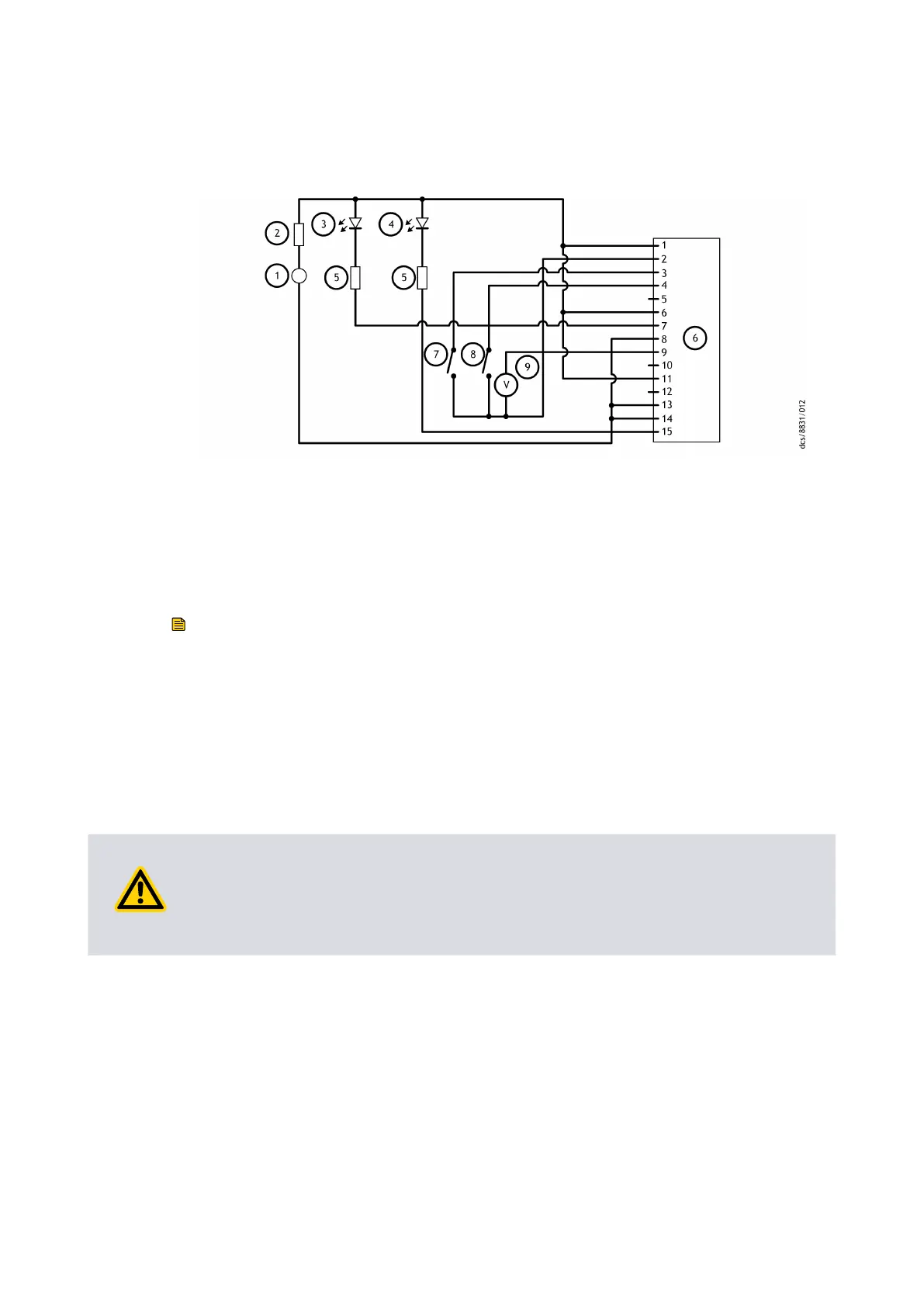

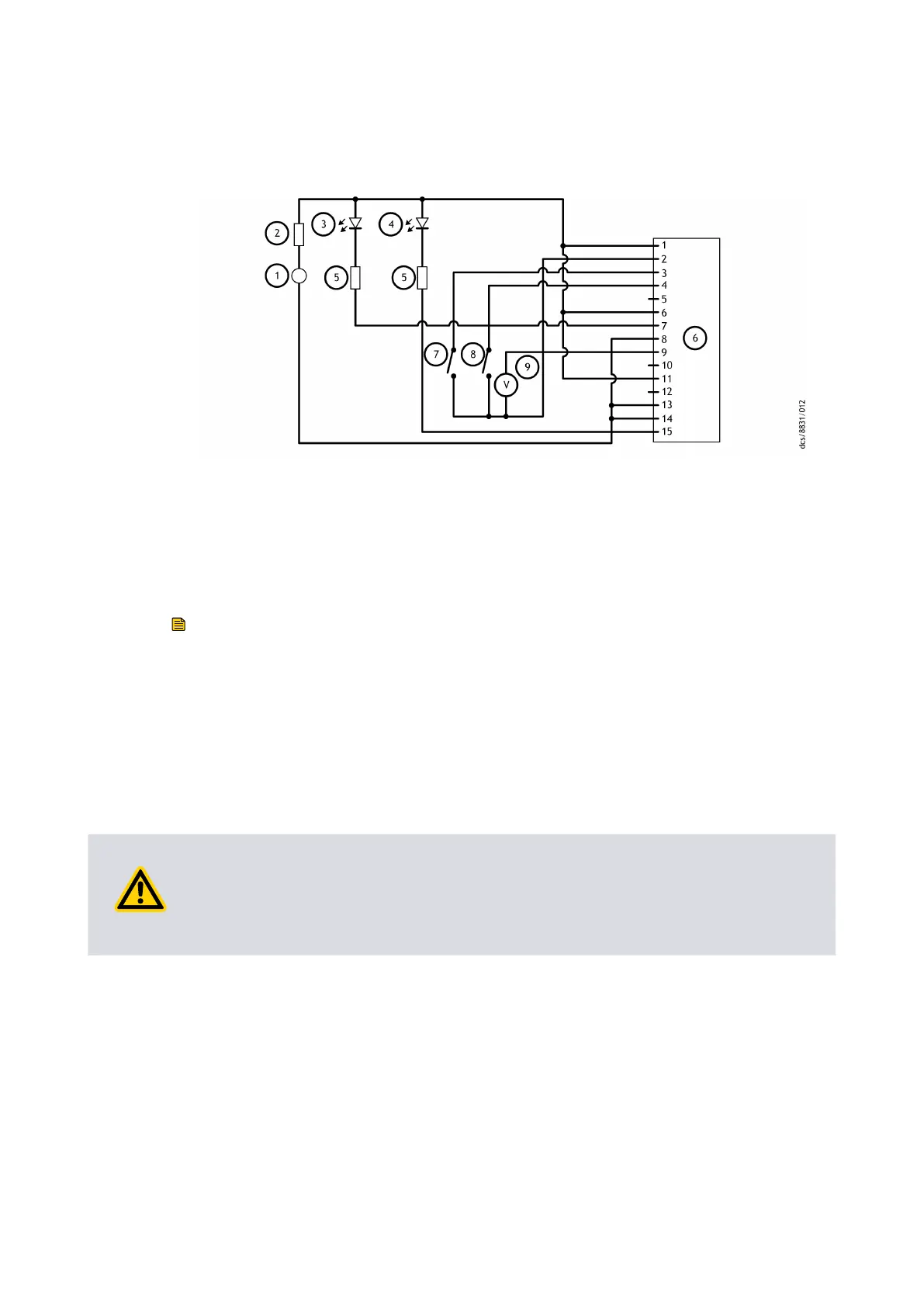

Figure 13 Logic interface connecons - parallel control

1. 24 V d.c. electrical supply 2. Fuse

3. Oponal LED indicat

or ‑ system OK 4. Oponal LED indicator ‑ normal speed

5. Current limit resistor for LED 6. nEXT pump logic interface

7. Start switch 8. Oponal standby switch

9. Oponal voltmeter to monitor analogue

output

1. 24 V d.c. electrical supply 2. Fuse

3. Oponal LED indicator ‑ system OK 4. Oponal LED indicator ‑ normal speed

5. Current limit resistor for LED 6. nEXT pump logic interface

7. Start switch 8. Oponal standby switch

9. Oponal voltmeter to monitor analogue

output

Note:

The volt

age supply to the pump controller can be more than 24 V. But the circuits

connected to the normal and fail line must have maximum external pull‑up voltage

rang as given in Table: Logic interface technical data.

4.6 Connect the parallel control and monitoring

To make the connecons for the parallel control and monitoring, use an applicable

mang half (not supplied).

CAUTION: BACK EMF SUPPRESSION DIODE

Risk of damage t

o equipment. If the normal and fail lines are used to drive the coils of

the d.c. relays, install a back EMF suppression diode in parallel with each relay coil to

protect the pump.

Connect the customer control equipment to the control input pins of the customer logic

interface mang half. Refer to Table: Logic interface connector pins to idenfy the

connector pins of the logic interface.

The control inputs are:

▪ Start

▪ Standby speed

To acvate one of the control inputs, connect the control input pin to the 0 V control

reference. To start the pump, connect the pin 3 (Start / Stop) to the pin 2 (0 V reference).

To stop the pump, remove the connecon between the pin 3 and pin 2. To put the pump

in standby, connect the pin 4 (Standby) and pin 3 (Start / Stop) to pin 2 (0 V reference).

04/2022 - ©Edwards Limited

Page 46B80000880_G

B80000880_G - Ins

t

allaon

Loading...

Loading...