User Instructions

MAN-02-04-60-0350-EN Rev. 3 February 2019

72

Section 14: Lubricant Recommendation and Requirements

Lubricant Recommendation and Requirements

Section 14: Lubricant Recommendation

and Requirements

14.1 Main Body: -25 to +60°C

Operating oil: DIN 51 517-CLP-HC

i.e. fully synthetic high-performance gear oils based on poly-alpfa-olens (PAO)

• Viscosity class: 320 ISO VG

• Lubricant requirement: 0,25 Lt

14.2 Output Type A and Spindle Drives

(Linear Actuators) -40 to +85°C

Grease DIN 51862- G 1 -G

il. e. water repellent complex grease on Al-soap base with high resistance to acids and alkalis

• Temperature range: -40 bis +85 C

• Worked penetration 0,1 mm: um 265

• Dripping point: ca. 260 C

• NLGI-Class: 1

• acid-free, not or only slightly reactive with water

14.3 Basic Lubricant Service Interval

Bettis actuators must be serviced 10 years after delivery by Bettis Antriebstechnik GmbH,

A-1230 Vienna The functionality and durability of the lubricant is however contingent upon

the operating conditions. Where appropriate reduction factors must be considered.

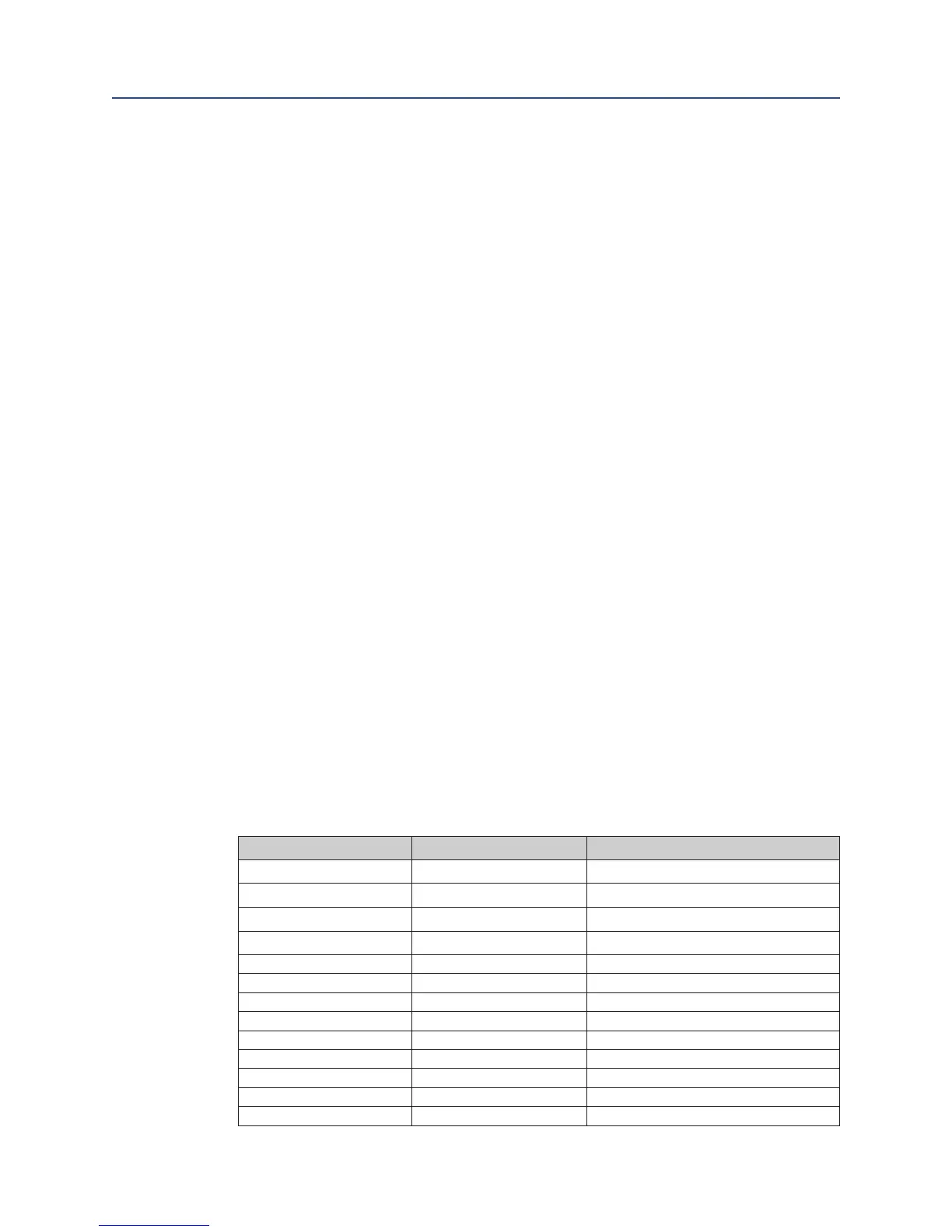

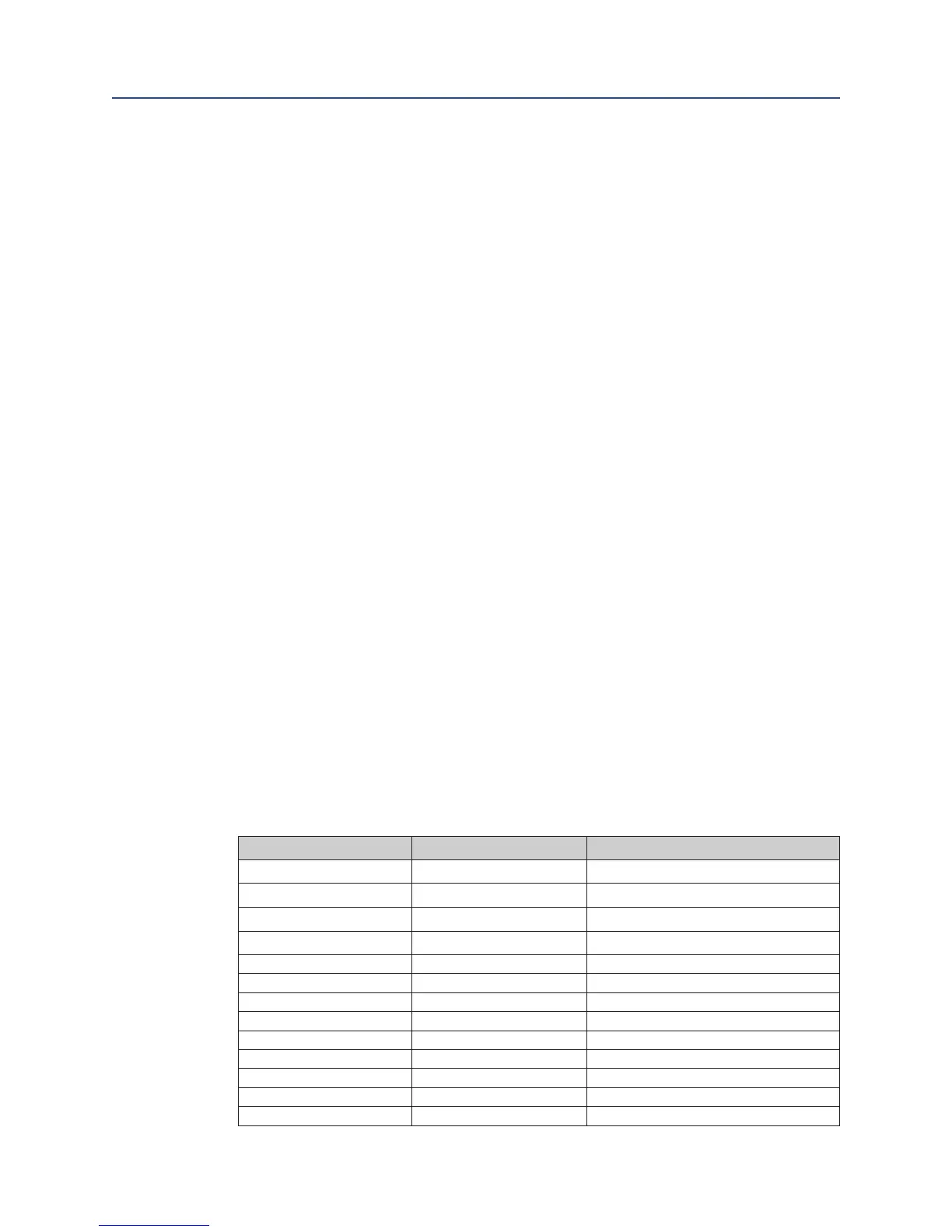

Table 31. Reduction Factors

Operating condition (s) Definition Reduction factor (multiplier)

Duty time Dt (Total engine running time)

Extremely high DT over 1250 hours/year 0,5

High DT over 500 hours/year 0,7

Extremely low DT less than 0,5 hours/year 0,8

Ambient temperature (permanent or long-term)

Extremely changeable between -10 and +50 °C 0,5

Extremely high above +50 °C 0,7

Extremely low below - 25 °C 0,9

Output speed (on actuator main shaft)

High speed over 80 U/min 0,8

Utilisation (relative to rated power)

Very high über 90% 0,8

high between 80 and 90% 0,9

Loading...

Loading...