EPSON AcuLaser C1900/AcuLaser C900 Revision B

Troubleshooting Check Points and Remedy for Paper Jam 159

3.4 Check Points and Remedy for Paper Jam

3.4.1 Initial Checking

If any paper jam has occurred, check the initial check items as listed below first. If any

problem is found as a result of initial checking, take an appropriate action for solution.

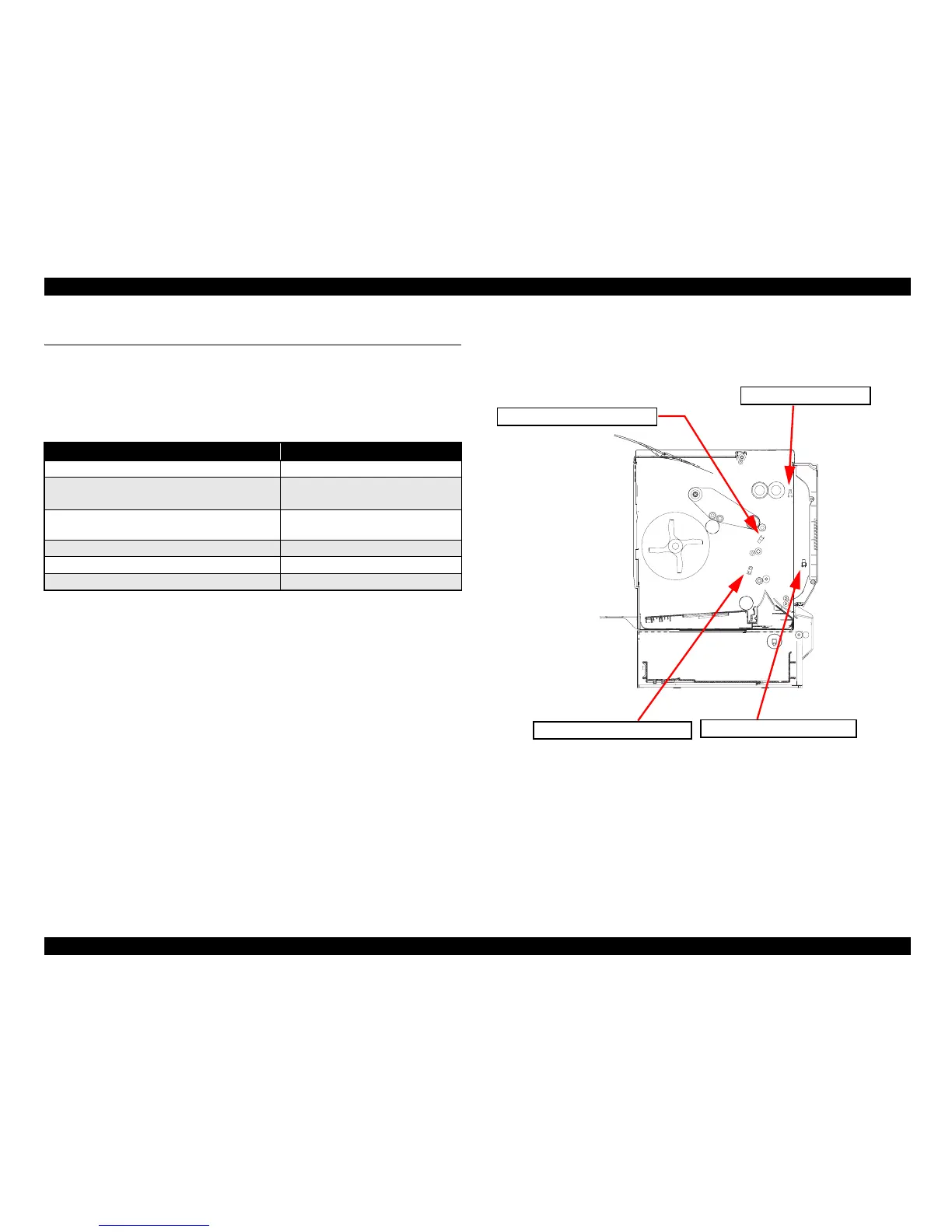

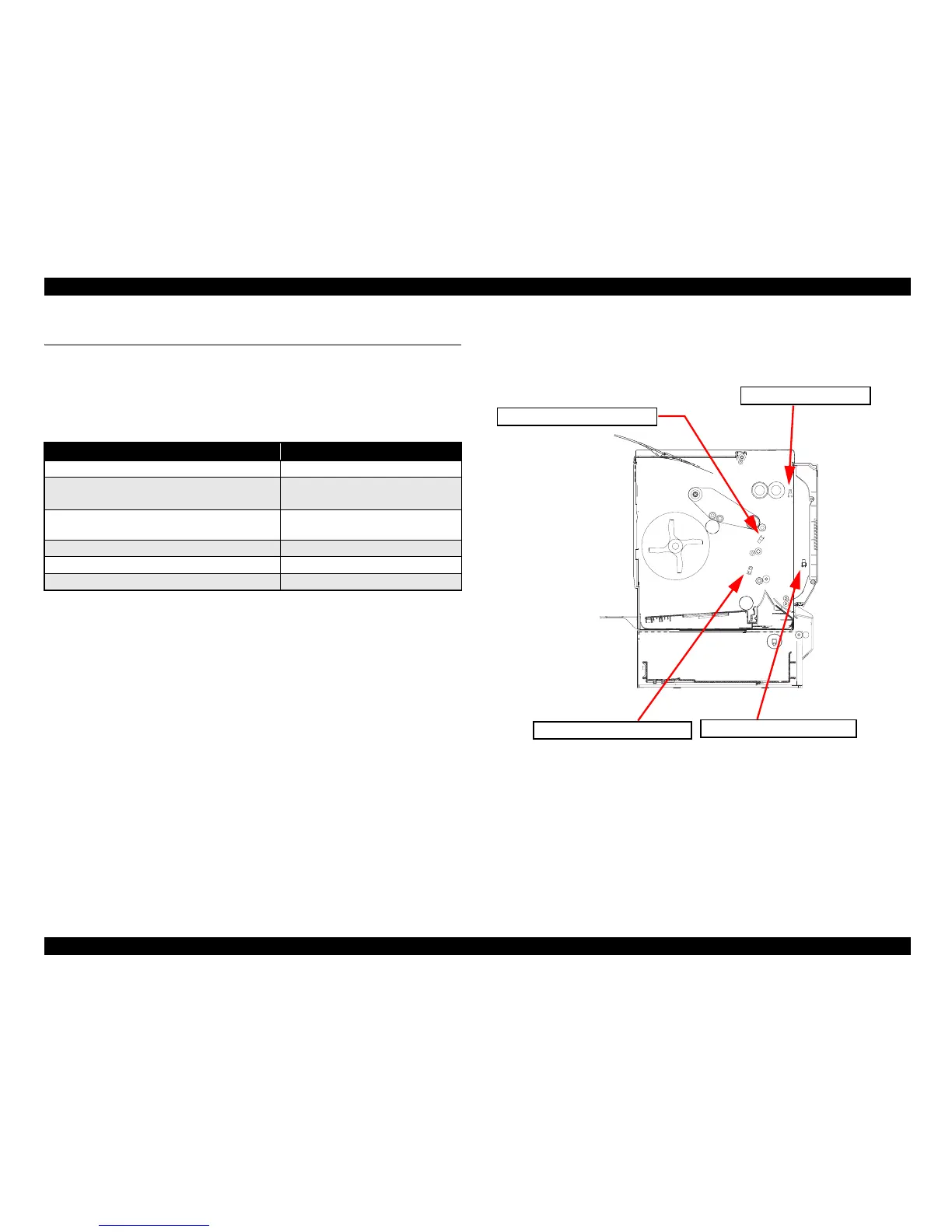

3.4.2 Locations of Jam Detection Sensors

When Duplex Unit and 500-sheet Cassette Unit are installed

Figure 3-2. Locations of Jam Detection Sensors

Table 3-1.

Check Item Solution

Is the paper used as specified? Replace the paper.

Is the paper free from curling, waving or moisture? Replace the paper.

Tell the customer how to store paper.

Is the paper path free from foreign matters, dirt or

deformation?

Clean the paper path or replace relevant

parts.

Are the rollers free from dirt, deformation or wear? Clean or replace the relevant roller.

Is the paper size consistent with the restraint plate? Ensure consistency.

Do the actuators operate normally? Repair or replace the relevant actuator.

Fusing Loop Detection Sensor (PC11)

4011T055AA

Paper Eject Sensor (PC10)

Timing Roller Front Sensor (PC2)

Duplex Unit Transport Sensor (PC17)

Loading...

Loading...