Maintenance

Periodic Maintenance

Lubrication

Greasing the Machine

Grease with No . 2 lithium or molybden um g rease .

1. Diseng ag e the blade-control switc h (PTO) and

mo v e the motion-control lev ers outw ard to the

P ark position.

2. Shut off the mac hine , remo v e the k ey , and w ait

for all mo ving par ts to stop before lea ving the

operating position.

3. Clean the g rease ttings with a rag .

Note: Mak e sure to scrape any paint off the front

of the tting(s).

4. Connect a g rease gun to the tting .

5. Pump g rease into the ttings until g rease begins

to ooze out of the bearings .

6. Wipe up any ex cess g rease .

Greasing the Front Caster Pivots

Service Interval : Y early

Gr ease type: Lithium or molybden um g rease

1. R emo v e the dust cap and

adjust the caster pi v ots; refer to

Adjusting the Caster -Pi v ot Bearing ( pag e 40 ) .

Note: K ee p the dust cap off until y ou ha v e

nished g reasing the caster pi v ots .

2. R emo v e the hex plug .

3. T hread a g rease tting (1/4 inc h–28 taper thread)

into the hole .

4. Pump g rease into the tting until it oozes out

around the top bearing .

5. R emo v e the g rease tting from the hole .

6. Install the hex plug and dust cap .

Greasing the Caster-Wheel Hubs

Service Interval : Y early

Gr ease type: Lithium or molybden um g rease

1. P ark the mac hine on a lev el surface , diseng ag e

the PTO , and mo v e the motion-control lev ers

outw ard to the P ark position.

2. Shut off the mac hine , remo v e the k ey , and w ait

for all mo ving par ts to stop before lea ving the

operating position.

3. R emo v e the caster wheel from the caster forks .

4. R emo v e the seal guards from the wheel hub .

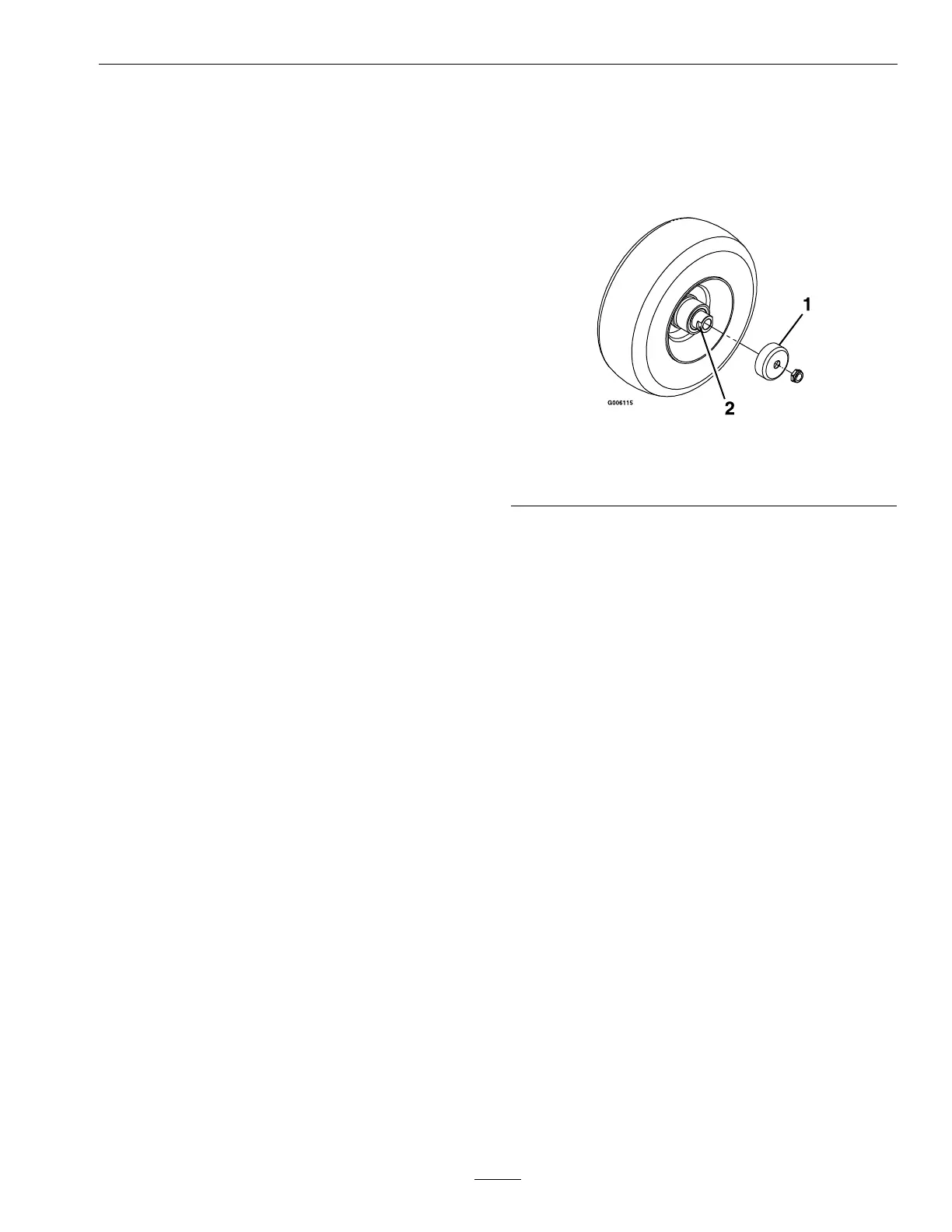

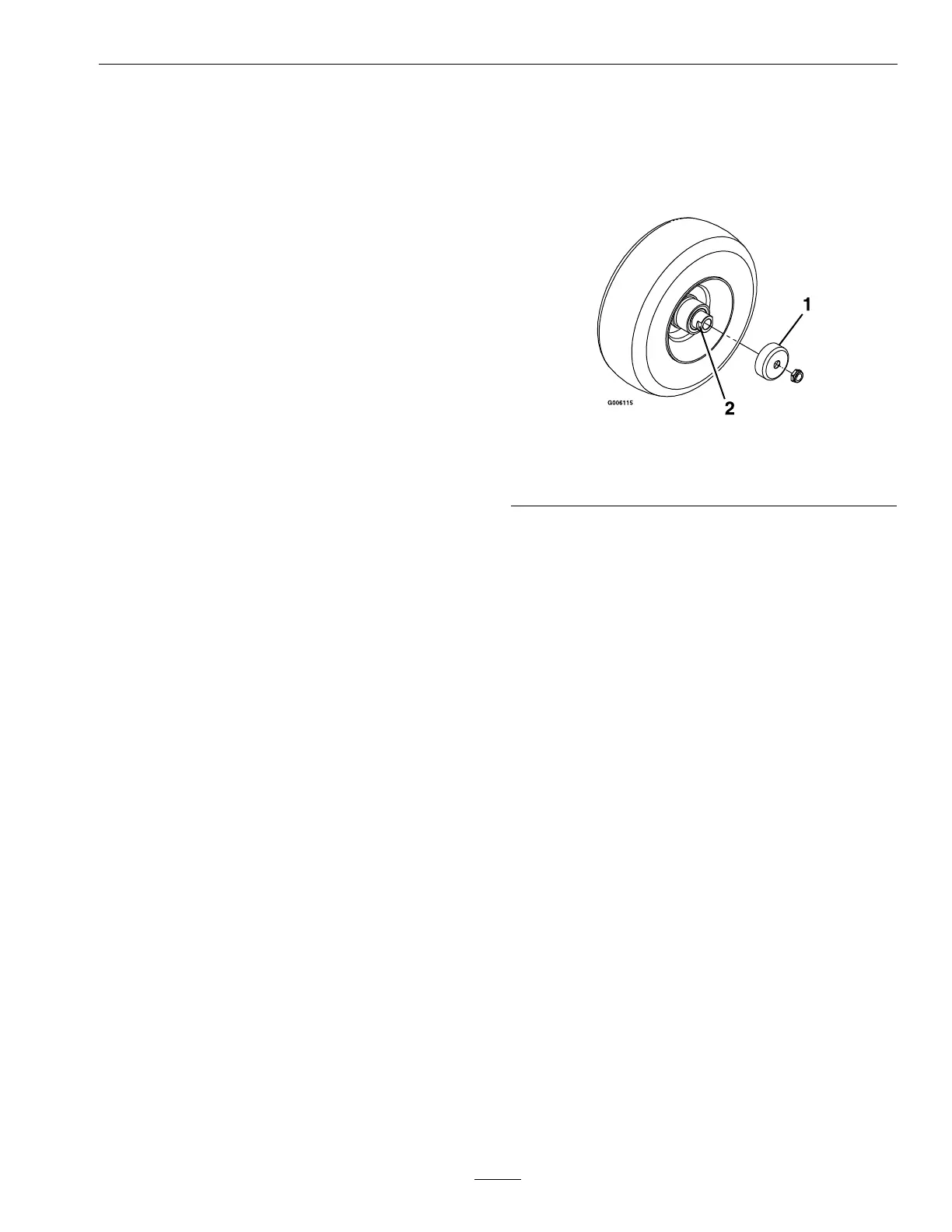

g006115

Figure 45

1. Seal guard 2. Spacer nut with wrench

ats

5. R emo v e 1 spacer n ut from the axle assembly in

the caster wheel.

Note: T hread-loc king adhesi v e has been applied

to loc k the spacer n uts to the axle .

6. R emo v e the axle with the other spacer n ut still

assembled to it from the wheel assembly .

7. Pr y out the seals , inspect bearings for w ear or

damag e , and re place them if necessar y .

8. P ac k the bearings with a g eneral-pur pose g rease .

9. Inser t 1 bearing and 1 new seal into the wheel.

Note: Y ou m ust re place the seals .

10. If both spacer n uts in the axle assembly ha v e been

remo v ed (or brok en loose), apply thread-loc king

adhesi v e to 1 spacer n ut, threading it onto the axle

with the wrenc h ats facing outw ard.

Note: Do not thread the spacer n ut all of the

w a y onto the end of the axle . Lea v e appro ximately

3 mm (1/8 inc h) from the outer surface of the

spacer n ut to the end of the axle inside the n ut.

11. Inser t the assembled n ut and axle into the wheel

on the side of the wheel with the new seal and

bearing .

12. With the open end of the wheel facing up , ll

the area inside the wheel around the axle full of

g eneral-pur pose g rease .

13. Inser t the second bearing and the new seal into

the wheel.

37

Loading...

Loading...