Maintenance, 10h

4812164601_C.pdf2023-01-05

Sprinkler system/Drum

Cleaning of sprinkler nozzle

3

2

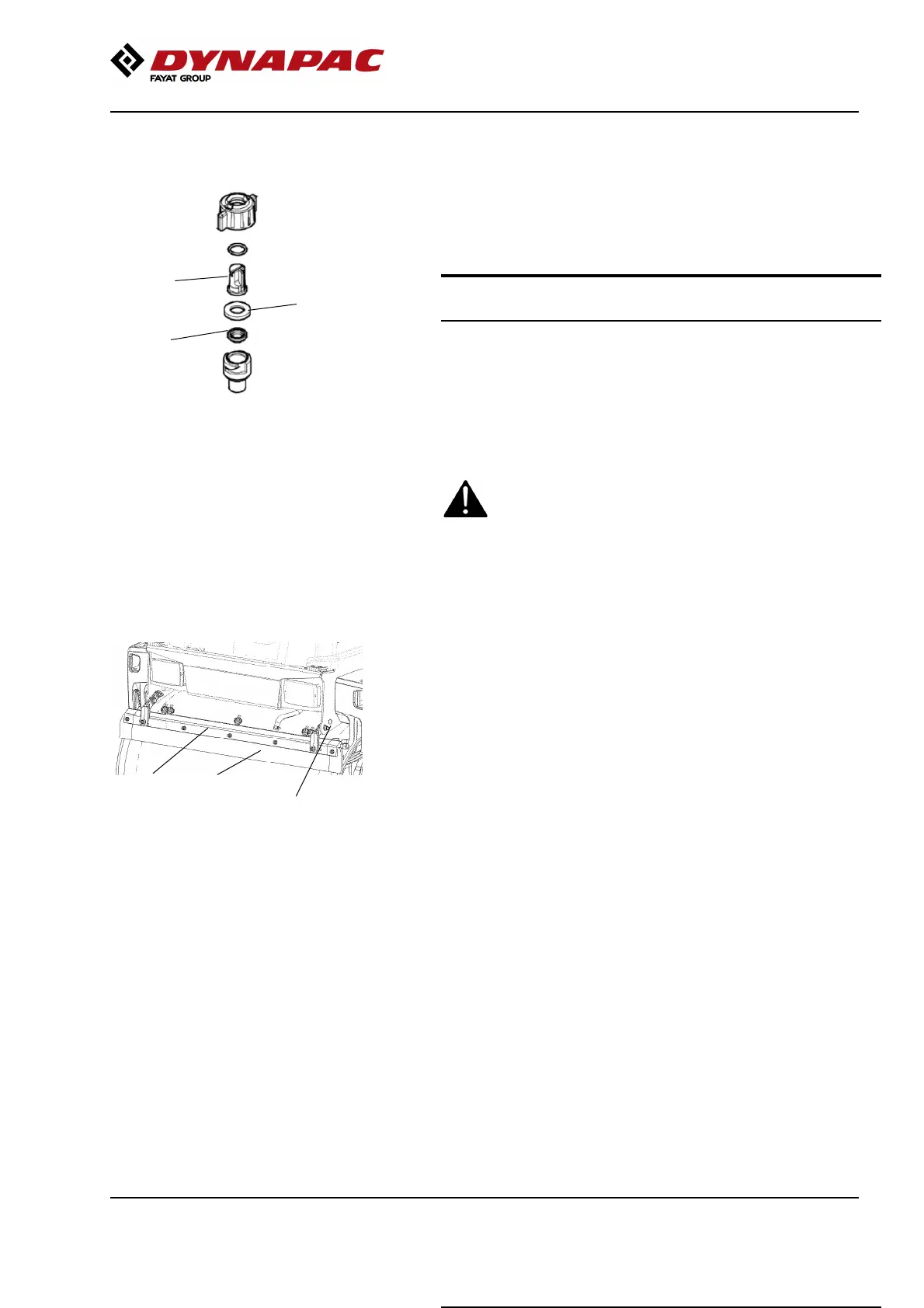

Fig. Nozzle

1. Nozzle

2. Gasket

3. Filter

1

Dismantle the blocked nozzle by hand.

Blow the nozzle (1) and fine filter (3) clean using

compressed air. Alternatively, fit replacement parts

and clean the blocked parts later on.

Nozzle Colour l/min (at 2.0

bar)

gal/min (at

40 psi)

Nozzle Colour l/min (at 2.0

bar)

gal/min (at

40 psi)

Standard yellow 0.63 0.20Standard yellow 0.63 0.20

Option blue 0.98 0.30Option blue 0.98 0.30

Option red 1.31 0.40Option red 1.31 0.40

Option brown 1.63 0.50Option brown 1.63 0.50

After inspecting and carrying out any necessary

cleaning, start the system and check that it works.

Wear protective goggles when working with

compressed air.

Wear protective goggles when working with

compressed air.

Scrapers, fixed

Checking - Setting

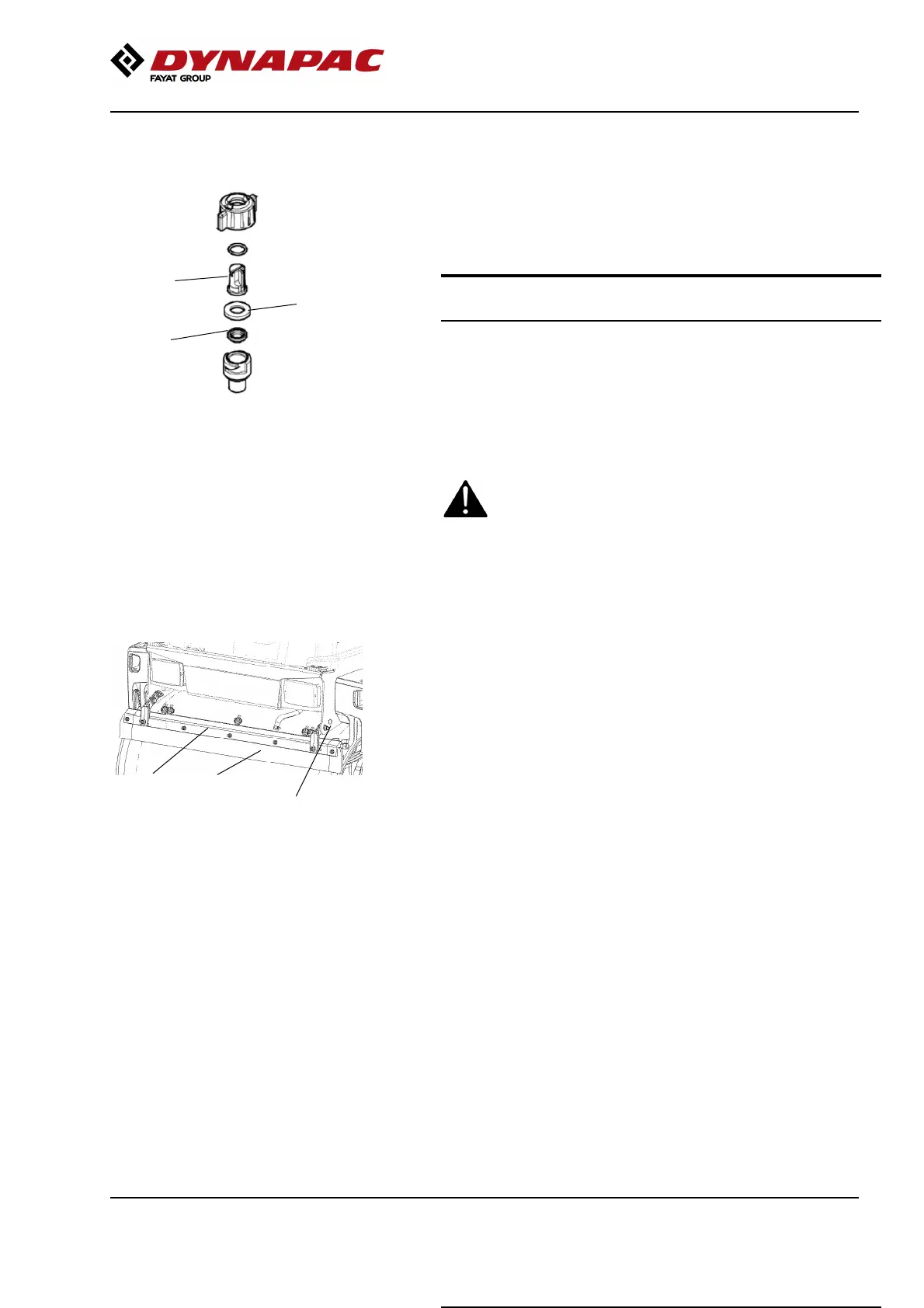

Fig. Drum

1. Scraper blade

2. Adjusting screws

3. Mounting plate

3

2

1

Make sure that the scrapers are undamaged. Adjust

the scrapers so that they are 1-2 mm from the drum.

For special asphalt compounds, it may be better if the

scraper blades (1) lie lightly against the drums.

Asphalt remnants can accumulate on the scraper and

affect the contact force. Clean as required.

Loosen the screws (2) to adjust the contact pressure

of the scraper blade against the drum.

Lock this setting by tightening the lock nut (2) against

the mounting plate (3).

Adjust the contact surface

on both scraper attachments.

Remember to tighten all the screws

after any adjustment.

127

Loading...

Loading...