5. Diagnosis and error treatment

5-5

Festo P.BE-SPC11-SYS-ASI-EN en 0203NH

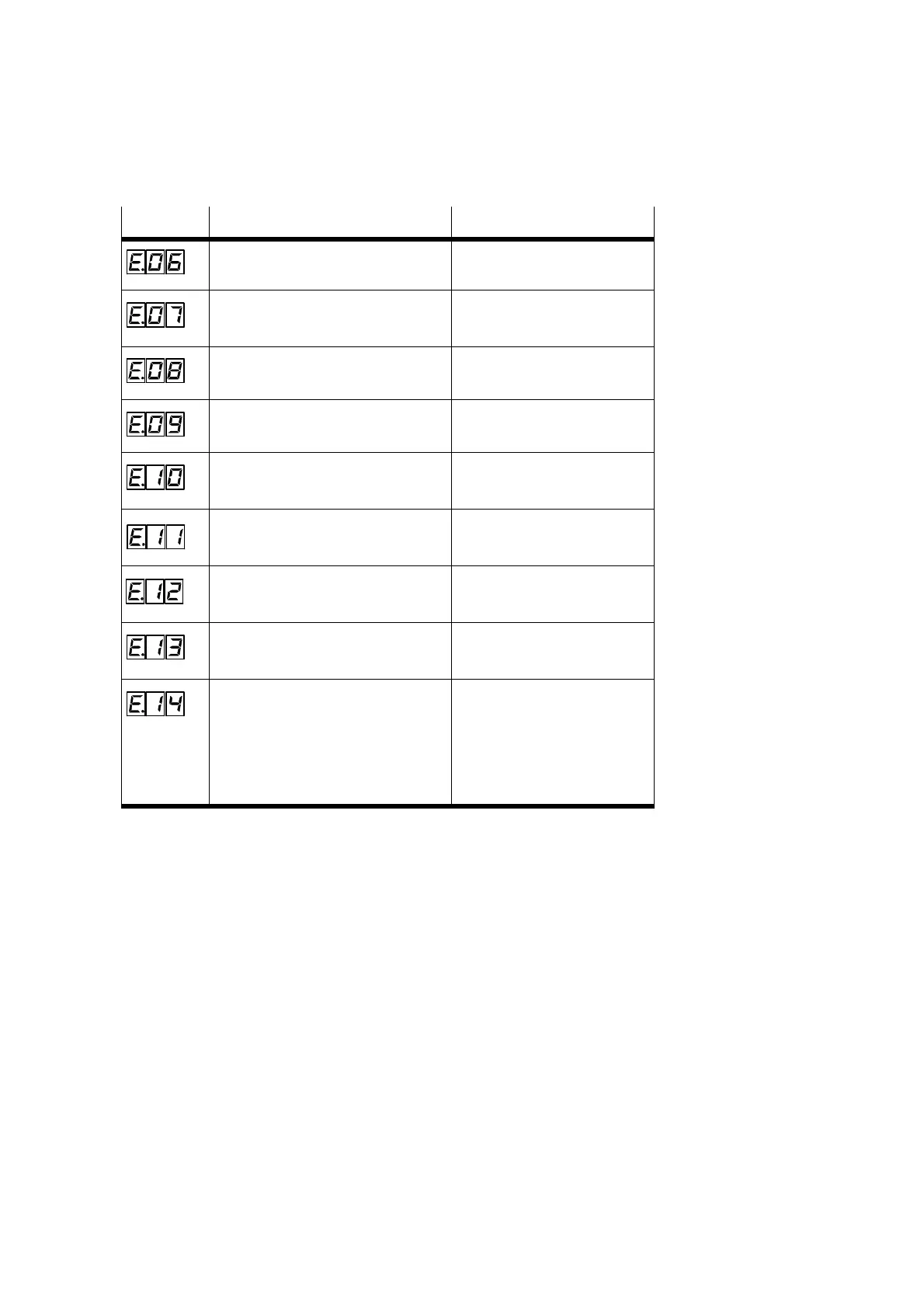

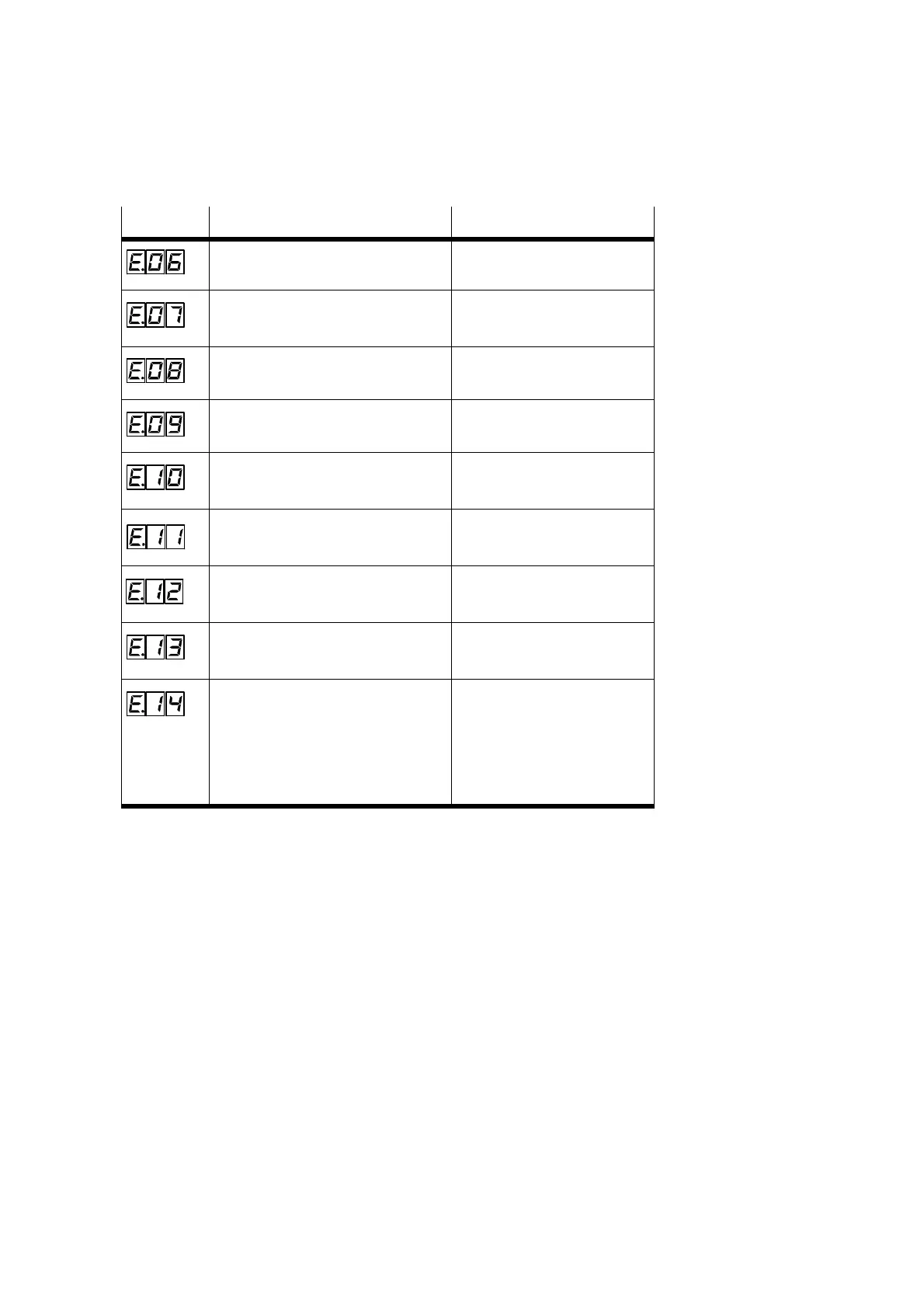

Fault no. Eliminating faultsOperating status

Amplification stage, cushioning stage or

system parameter set incorrectly.

S Correct the parameters

The measuring system has no valid length

code (non-permitted measuring system

length or length code does not exist).

Ser vicing required

SPC11 damaged ( E EPROM-ACK fault). S Replace the SPC11

Measuring system type is not supported

(invalid measuring system ID read).

S Replace the measuring system

Communication to T emposonics is faulty

(non-plausible data has been received).

S Check the measuring system

length or replace the measuring

system.

Communication to T emposonics is faulty

(non-plausible data has been received).

S Check the measuring system

length or replace the measuring

system.

Incorrect direction of movement ascertained

during positioning stroke; tubing is incor-

rectly connected.

S Correct the tubing of the propor-

tional directional control valve.

Time out, The position c annot be reached

fast enough (positioning timeout approx.

10 s).

S Removeobstructioninpositioning

path or check compressed air

supply.

Intermediate position does not exist or is

outside the permit ted positioning range.

S Increase the positioning range

and teach the end positions

again, in order that the intermedi-

ate positions lie within the per-

mitted positioning range.

or

S Teach the intermediate positions

again.

Loading...

Loading...