5. Diagnosis and error treatment

5-7

Festo P.BE-SPC11-SYS-ASI-EN en 0203NH

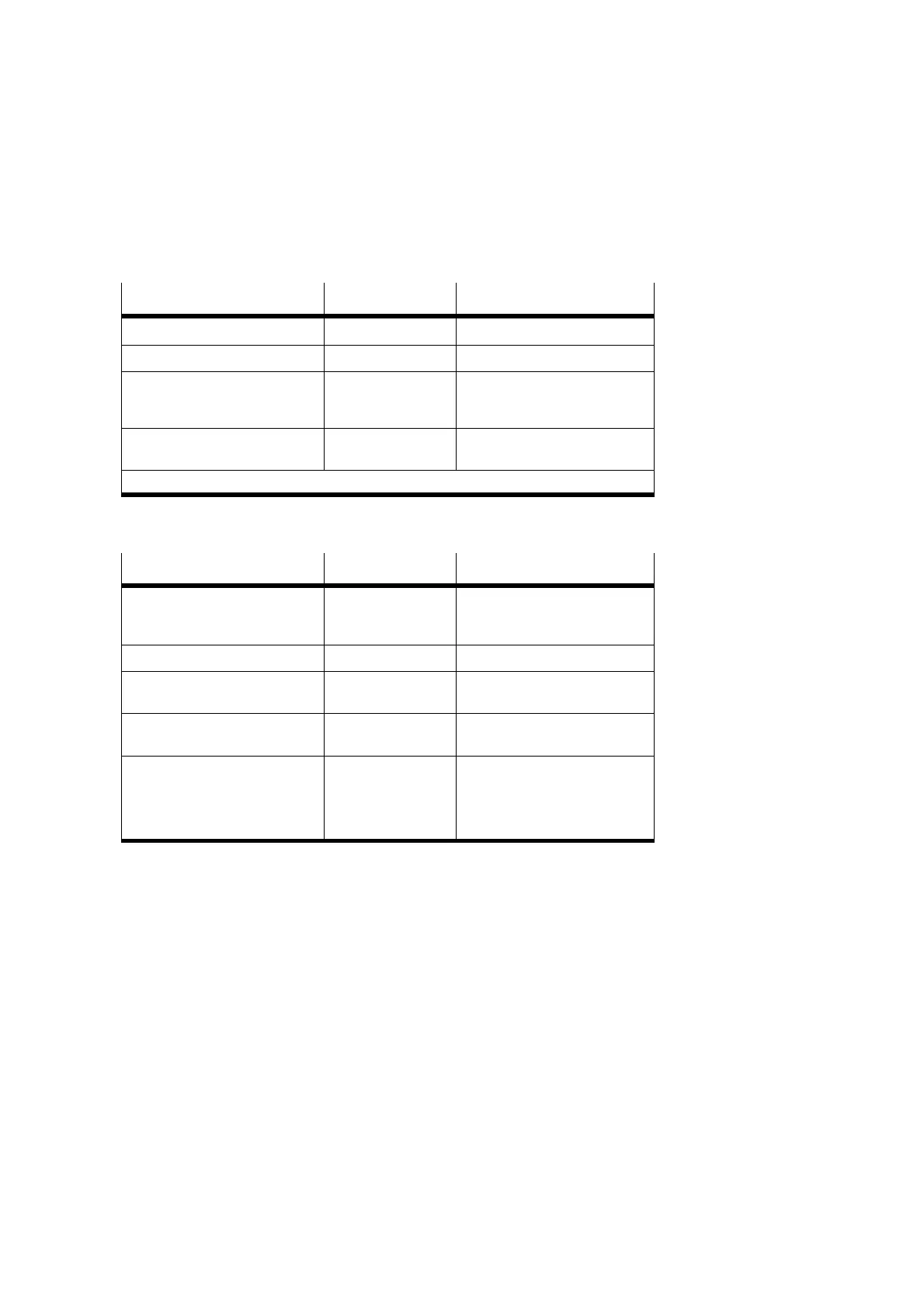

5.3 Faults during operation

1)Themassdoesnotmove.

Cause

Remedy Remarks

No supply pressure Check 5...7 bar required

Valve cable not connected correctly Check See section 3.3.5

Proportional directional control

valve is defective

Check and, if necess-

ary, replace

You can check through the viewing

windowtoseeifthevalveslide

jams.

1)

There are several simultaneous

positioning orders

Check input bits

P.01...P.04

Theremustonlybeonepositioning

order

1) See operating instructions for valve MPYE-5-...

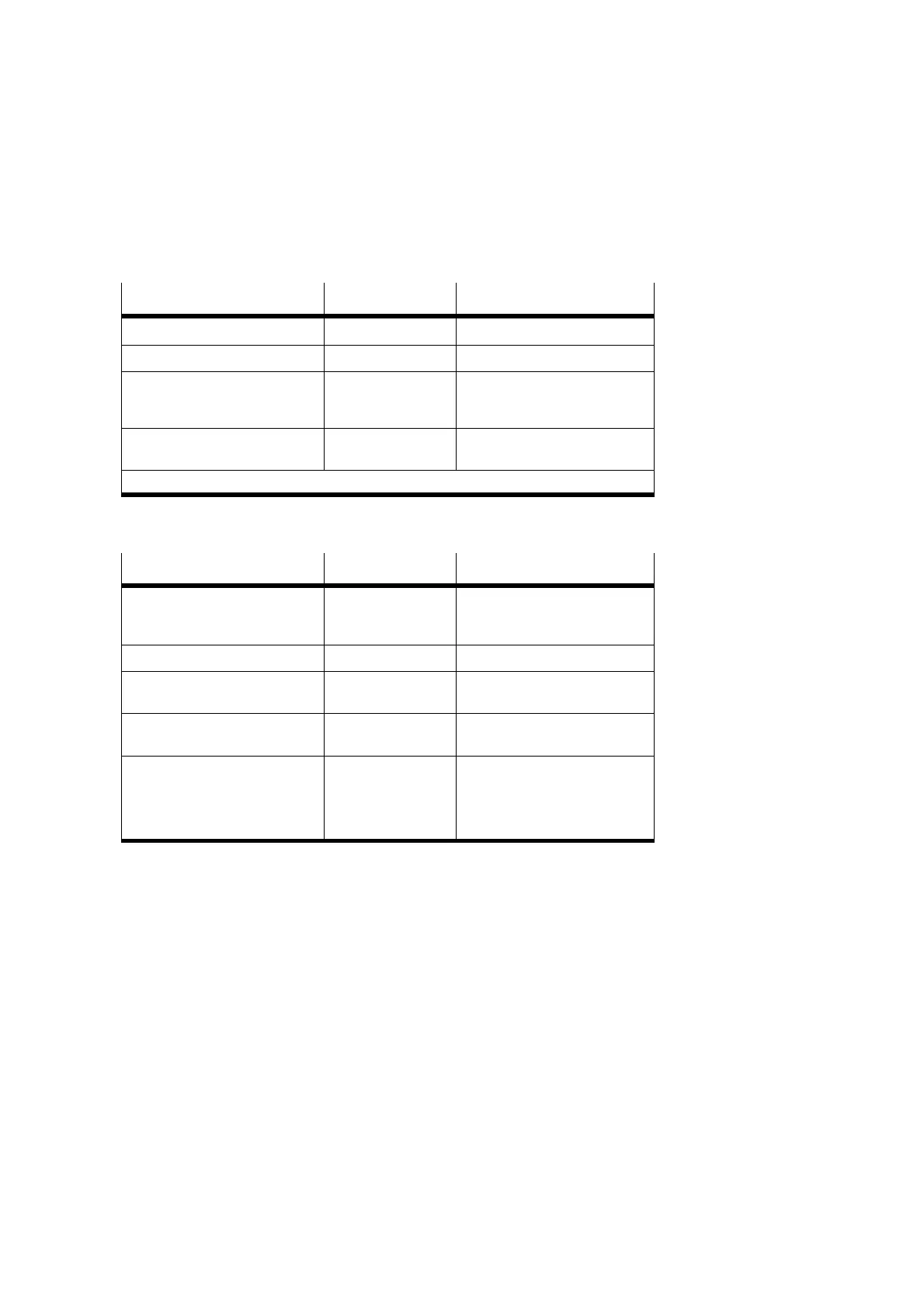

2) Bad behaviour during mo vement to end position.

Cause

Remedy Remarks

System is not mounted correctly Check fitting and

mechanical parts

Check measuring system and drive

for parallelism, mechanical play

and sluggishness

System is not earthed correctly Check See chapter 3

Parameters are not set optimally Check parameters See manual “Drive-specific supple-

ment”

High fluctuations in supply pressure

(

> 0.5 bar)

Check the supply

pressure

If necessary, fit a compr essed air

reservoir

Non-permitted mass load Check mass load and

parameters

If necessary, place a basic loa d in

position, in order that the maximum

permitted value range is not ex-

ceeded during positioning with

different masses.

Loading...

Loading...