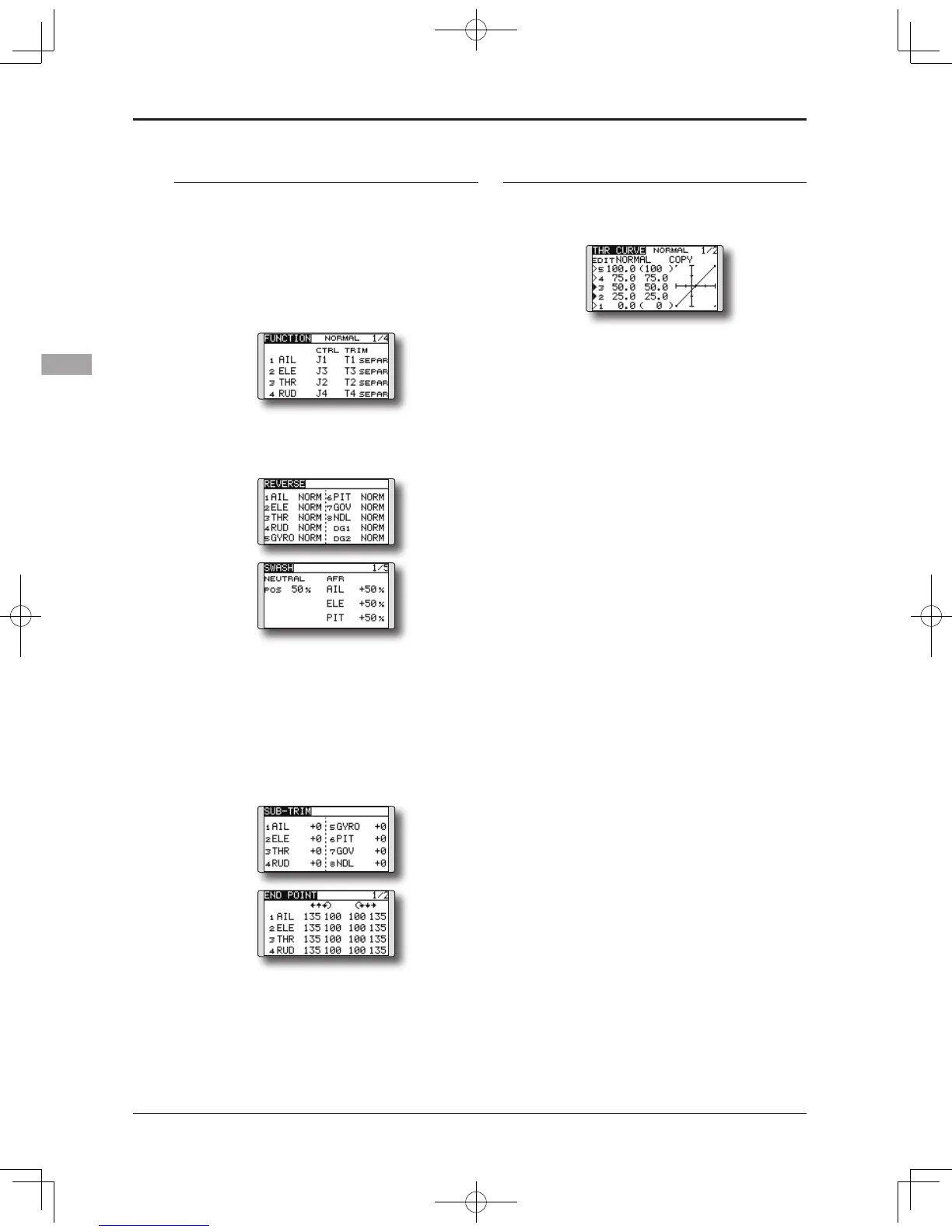

5. Throttle/Pitch curve setting

This function adjusts the throttle or pitch

operation curve in relation to the movement of the

throttle stick for each condition.

<Throttle curve setting example>

Activate the throttle curve of each condition with

the condition select switch.

●Normalcurveadjustment

Normal curve creates a basic throttle curve

centered near hovering. This curve is adjusted

together with the pitch curve (Normal) so that the

engine speed is constant and up/down control is

easiest.

●Idleupcurveadjustment

The low si de Th rottle curve creates a curv e

matched for aerobatics (loop, roll, 3D, etc.).

●Throttleholdcurveadjustment

The curve is not used when performing auto rotation

dives.

Conrmthattherateoftheslowestposition(0%)of

thestickis0%(initialsetting).

<Example of pitch curve setting>

Activate the pitch curve of each condition with

the condition select switch.

●Pitchcurve(Normal)

Make the pitch at hovering approximately +5

º

~6

º

.

Set the pitch at hovering with the stick position at

the50%pointasthestandard.

*Stability at hovering may be connected to the throttle curve.

Adjustment is easy by using the hovering throttle function

and hovering pitch function together.

●Pitchcurve(Idleup1)

The idle up 1 pitch curve function creates a curve

matchedtoairborneight.

Set to -7

º

~+12

º

as standard.

●Pitchcurve(Idleup2)

The high side pitch setting is less than idle up 1.

The standard is +8

º

.

●Pitchcurve(Hold)

At auto rotation, use the maximum pitch at both

the high and low sides.

[Pitch angle setting example]

Throttle hold: -7

º

~+12

º

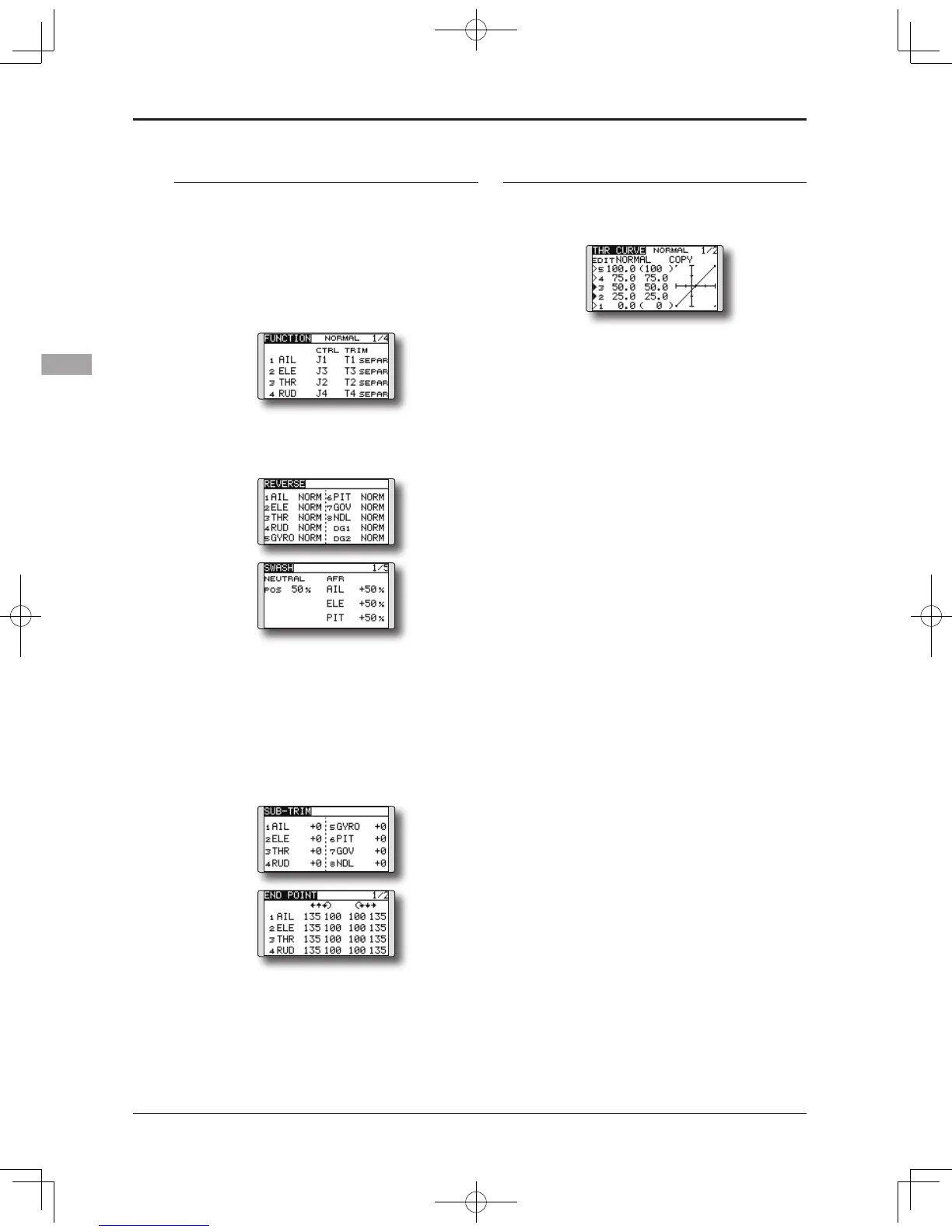

4. Servo Connection

Connect the throttle rudder, aileron, elevator,

pitch, and other servos in accordance with the

kit instruction manual. For a description of the

connection method, see "Receiver and Servos

Connection".

Note: The channel assigned to each function

can be checked at the Function menu of the

Linkage Menu.

● If the direction of operation of the servo

is incorrect, use the Reverse function of

the Linkage Menu. Also use the swash AFR

function in other than the H-1 mode.

●Adjustthedirectionofoperationofthegyro.

(Gyro side function)

● Connect the throttle linkage so that the

carburetor can fully close at full trim throttle

cut.

●Adjusttheneutralpositionatthelinkageside

andnetunewiththeSub-Trimfunctionand

End Point function. To protect the linkage,

a limit position can also be set with the End

Point function.

●Swashplatecorrection(ExceptH-1mode)

*If any interactions are noticed, for a description of the

linkage correction function, please refer to the SWASH

function, p.65.

Loading...

Loading...