3. Control mode: SV and PMSV (00-00=3,4)

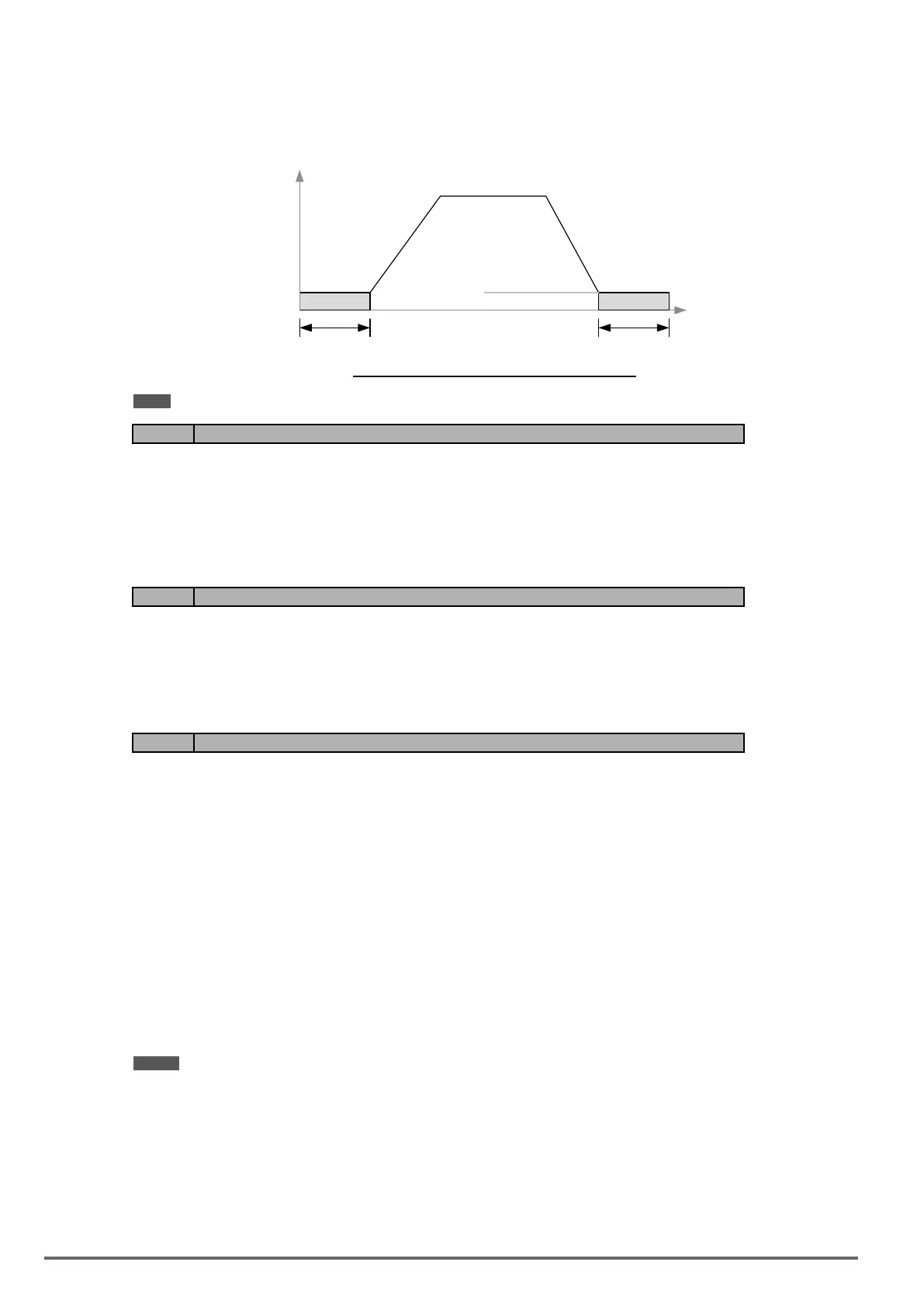

It start zero-speed operation by the time 07-16. Deceleration to stop is according to 07-06 and 07-08. When

output frequency is lower than 07-06 in deceleration time, It start zero-speed operation by the time 07-08.

07 - 16 07 - 08

07 - 06 (Braking start

frequency)

Or 01 - 08 (Fmin)

Zero-

Speed

Operation

Zero-

Speed

Operation

Output

frequency

Time

Figure4.4.57cSVandPMSVzero-speedoperation

Note: When 07-06<01-08, It start zero-speed operation by the setting frequency (01-08).

Code Parameter Name / Range

07-07 DC injection braking current

0~100 %

DC Injection braking current as percentage of the inverter rated current. Increasing this level will increase the

amount of heat generated by the motor windings. Do not set this parameter higher than the level necessary to

hold the motor shaft.

Code Parameter Name / Range

07-08 DC injection braking time at stop

0.00~10.00 s

Duration of DC injection braking during a stop operation. DC injection braking at stop is disabled when parame-

ter 07-08 is set to 0 sec.

Code Parameter Name / Range

07-16 DC injection braking time at start

0.00~10.00 s

Duration of DC injection braking during a start operation. DC injection braking at start is disabled when parame-

ter 07-16 is set to 0 sec.

DC Injection Braking Operation

When DC Injection braking is active DC voltage is applied to the motor, increasing the braking current and

resulting in an increase in the strength of the magnetic eld trying to lock the motor shaft.

To enable DC injection braking during a start operation set the DC injection braking current (07-07) and the

DC injection braking time (07-16) at start to a value greater than 0. DC injection braking at start can be used to

prevent “wind milling effect” in fan applications.

To enable DC injection braking during a stop operation set the DC injection braking current (07-07) and the DC

injection braking time at stop (07-08) to a value greater than 0.

Notes:

- When parameter 07-16 is set to 0 sec. (DC injection braking off). the inverter will start from the minimum output

frequency.

- Increasing the DC braking time (07-08, 07-16) can reduce the motor stop time.

- Increasing the DC braking current (07-07) can reduce the motor stop time.

- During stop operation: If the DC braking start frequency < minimum output frequency (01-08), DC braking is activat-

ed when the output frequency reaches the minimum output frequency level.

- DC Injection braking cannot be used in sensor vector control (SV).

For DC braking operation, please refer to Figure 4.4.57.

192 VDI100 • Instruction manual

Loading...

Loading...