CHAPTER

8

LUBRICATION

GENERAL

INFORMATION

ACAUTION

NEVER

attempt

to

lubricate

or

service

this

unit

when

any

part

of

the

machine

is

in

motion.

ALWAYS

BE

SURE

to

exercise

the

MANDATORY

SAFETY

SHUTDOWN

PROCEDURE

(page

10)

BEFORE

proceeding

to

lubricate

or

service

this

equipment.

NOTE:

The

Maintenance Log Chapter in this

manual

has provisions for recording the dates

and

Hourmeter

readings

after

lubrication

or

other

service

has

been

performed;

use those spaces

to

keep

a

log

for

maintaining

a

current

service

interval record.

Proper

routine lubrication

is

an

important

factor in

preventing

excessive

part

'Near

and

early

failure.

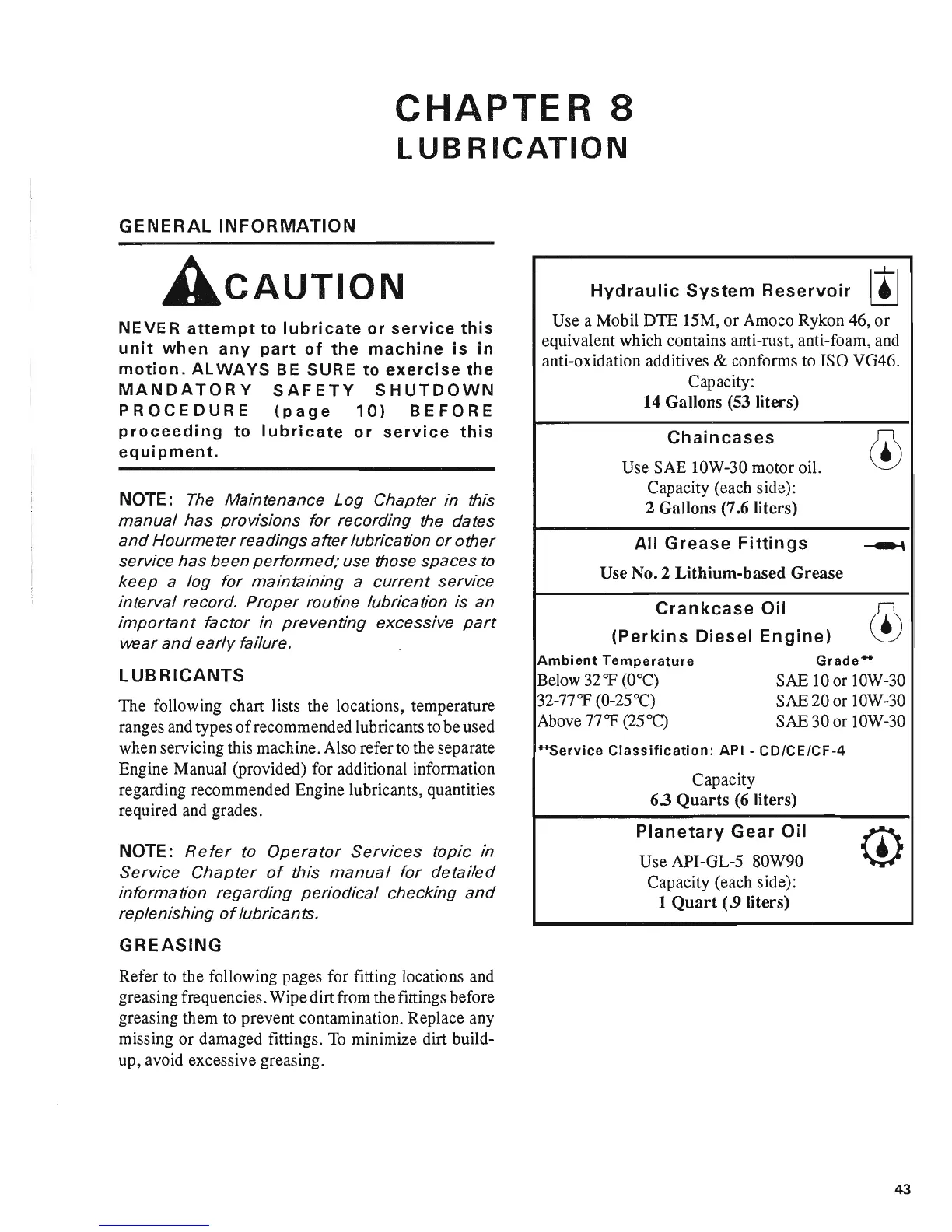

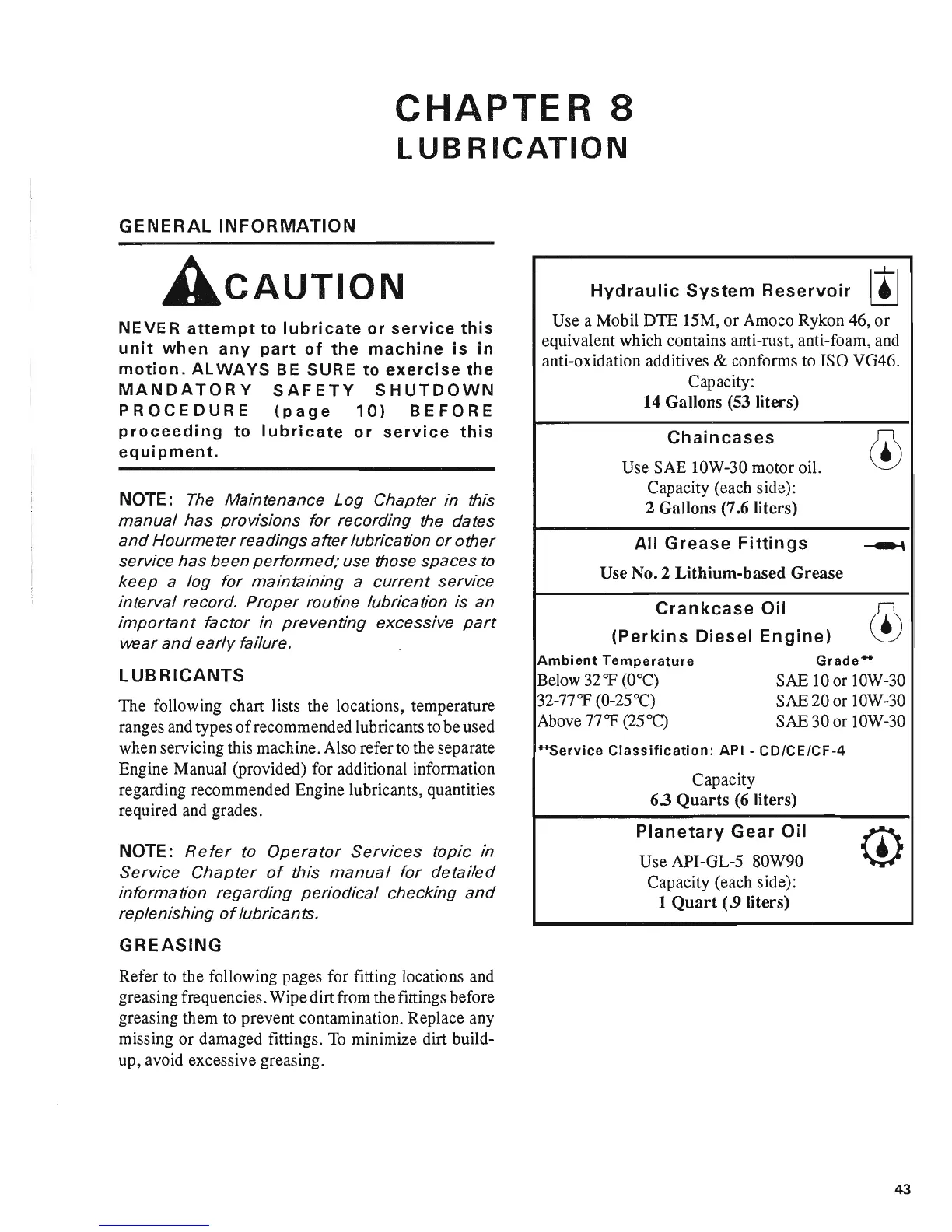

LUBRICANTS

The following chart lists the locations, temperature

ranges and types

of

recommended lubricants to be used

when servicing this machine. Also refer to the separate

Engine Manual (provided) for additional information

regarding recommended Engine lubricants, quantities

required and grades.

NOTE:

Refer

to

Operator

Services

topic

in

Service

Chapter

of

this

manual

for

detailed

informa tion regarding

periodical

checking

and

replenishing

of

lubricants.

GREASING

Refer

to

the following pages for fitting locations and

greasing frequencies. Wipe dirt from the fittings before

greasing them to prevent contamination. Replace any

missing

or

damaged fittings.

To

minimize dirt build-

up, avoid excessive greasing.

Hydraulic

System

Reservoir

It I

Use a Mobil DTE 15M,

or

Amoco Rykon 46,

or

equivalent which contains anti-rust, anti-foam, and

anti-oxidation additives

& conforms to ISO VG46.

Capacity:

14 Gallons

(53

liters)

Chaincases

Use SAE 10W-30 motor oil.

Capacity (each side):

2 Gallons (7.6 liters)

All

Grease

Fittings

Use

No.2

Lithium-based Grease

Crankcase

Oil

(Perkins

Diesel

Engine)

Ambient

Temperature

Below 32"F

(O°C)

32-77"F (0-25°C)

Above 77

"F

(25°C)

Grade++

SAE

10

or

lOW

-30

SAE 20 or lOW-30

SAE 30 or lOW-30

++Service

Classification:

API

-

CD/CE/CF-4

Capacity

63

Quarts

(6 liters)

Planetary

Gear

Oil

Use API-GL-5 80W90

Capacity (each side):

1

Quart

(.9 liters)

43

Loading...

Loading...