CHECK TIRE PRESSURES

AWARNING

Inflating

or

servicing

tires

can

be

dangerous.

Whenever

possible,

trained

personnel

should

service

and/or

mount

tires.

Do NOT

place

your

fingers

on

the

tire

bead

or

rim

during

inflation;

serious

injury

or

amputation

could

result.

To

avoid

possible

death

or

serious

injury,

follow

the

safety

precautions

below:

D BE SURE the Rim

is

clean and free of rust.

D Lubricate both the tire beads and rim flanges with

a soap solution.

Do

NOT use

oil

or

grease.

D

Use

a clip-on tire chuck with a remote hose

and

gauge which allows you to stand clear of the tire

while inflating it.

D NEVER inflate beyond 35 PSI (240 kPa) to seat

the beads.

If

the beads have NOT seated by the

time the pressure reaches 35 PSI, deflate the as-

sembly, reposition the tire on the rim, relubricate

both parts and re-inflate. Inflation pressure be-

yond 35 PSI with unseated beads may break the

bead

or

rim with explosive force sufficient to cause

death

or

serious injury.

D After seating the beads, adjust the inflation pres-

sure to the recommended operating pressure

listed.

D

Do

NOT weld, braze,

or

otherwise attempt to

repair

and

use a damaged rim.

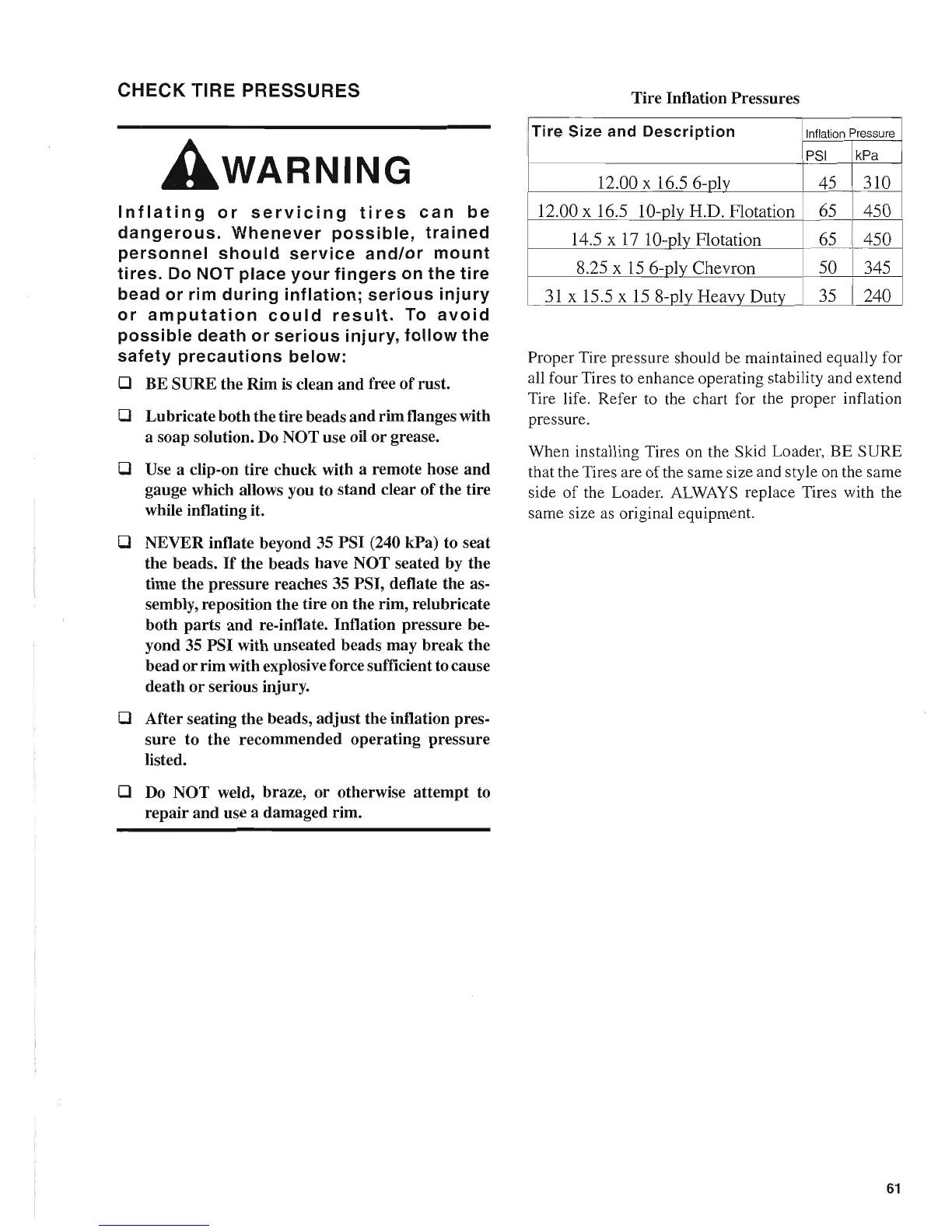

Tire Inflation Pressures

Tire

Size

and

Description

i .

i Inflalion Pressure

PSI

!

ikPa

12.00 X 16.5 6-ply

45

I

310

12.00

X 16.5 lO-ply B.D. Flotation

65

450

14.5

X

17

10-ply Flotation

65

450

8.25 x

15

6-ply Chevron

50 345

I

I

31

x 15.5 x

15

8-ply Heavy Dutv I

35 240

Proper Tire pressure should be maintained equally for

all four Tires to enhance operating stability and extend

Tire life. Refer to the chart for the proper inflation

pressure.

When installing Tires on the Skid Loader, BE SURE

that the Tires are

of

the same size and style on the same

side

of

the Loader.

ALWAYS

replace Tires with the

same size

as

original equipment.

61

Loading...

Loading...