294 Programming examples - Using fl ight phases

The mixing direction is to be selected

so that all fl aps are defl ected downward

with the elevator pulled up and defl ected

upward with the elevator pushed down (=

hydroplane). The mix proportion is normally

in the low double-digit range.

Now, within the »Wing mixers« menu, switch to the

"Brake settings" …

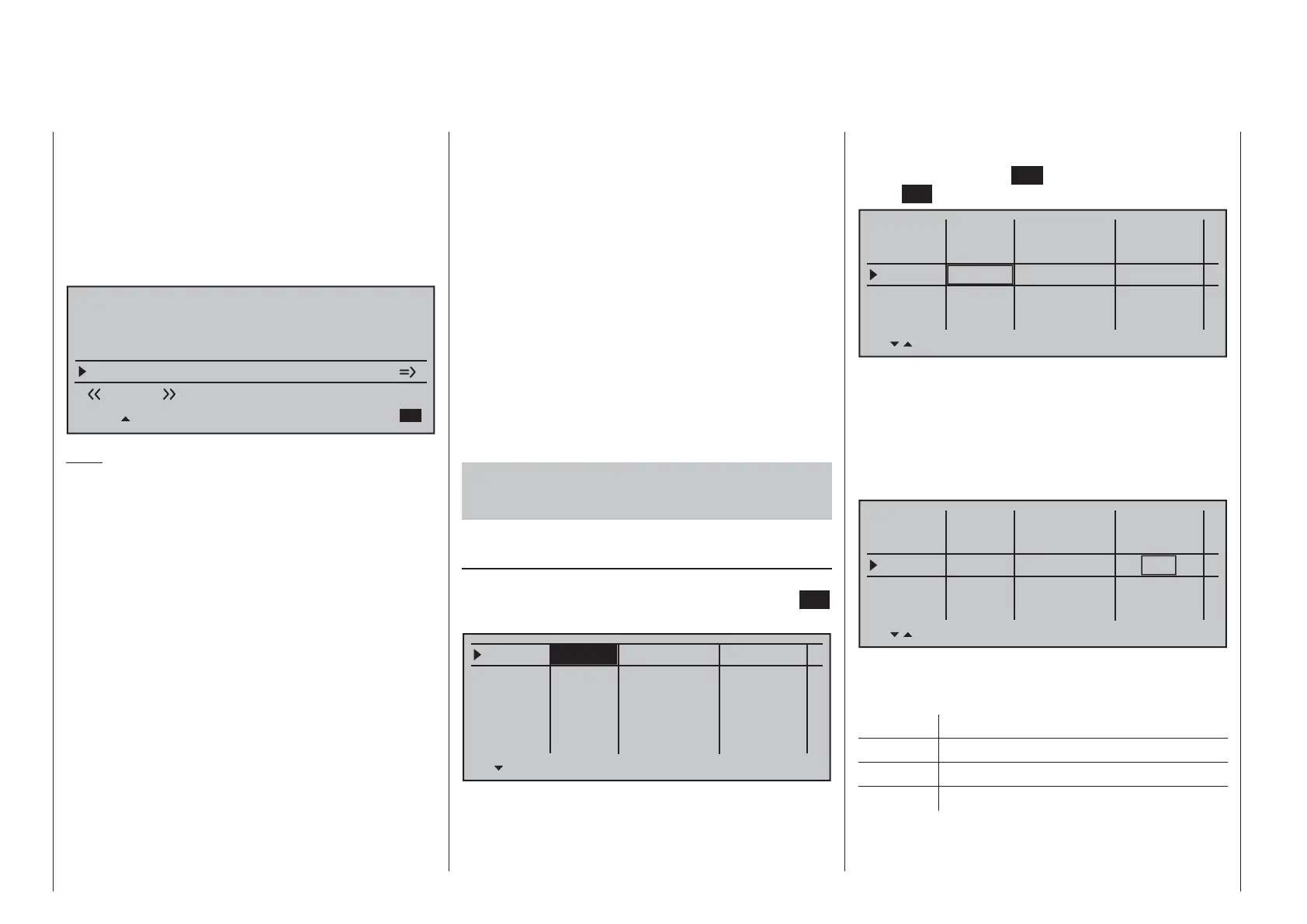

Elevat. curve

BRAKE SETTINGS

Normal

Crow

AI

+22%

WK2

0%

FL

+66%

Diff. reduct.

WK2

+33%

0%

+33%

Note:

The "Brake settings" menu is switched "off" if: "Motor

on C1 forward / back" in the »Model type« menu

(page 94) AND the "Motor" column of the »Phase

settings« menu, (page 142) are set to "yes" for the

currently active fl ight phase. Change the fl ight phase,

if applicable.

Crow Further above in this text section, the C1

joystick was set for brake fl ap steering.

In this line you determine the share

with which the AI and FL should be

included on actuation of C1 in the

manner that both ailerons are defl ected

"slightly" upward and both fl aps are

defl ected as far downward as possible.

Now with a simultaneous tap on the

ef keys of the left touch pad, a

change to the »Servo display« menu

can be affected for observation of servo

movements and, in particular, to ensure

that no infl uence on the fl aps takes

place above the adjusted brake offset,

e.g. +90 % and beyond to the throw

limit of the C1 control ("Idle travel" of

the C1 joystick).

Diff. reduct. The value previously entered into

the aileron differentiation line should

also be entered in this "Differentiation

reduction" line to fade this out during

braking.

Elevat. curve

This line is used for the entry of any

correction factor that may be required

for the elevator, see page 174.

Insofar as necessary, again check all fl ap throws and,

by way of the »Servo adjustment« menu, adjust the

servo center, the servo travel and the travel limit.

It may also be time to start the initial fl ight testing,

insofar as all global settings – that is to say, all fl ight-

phase independent settings – are completed.

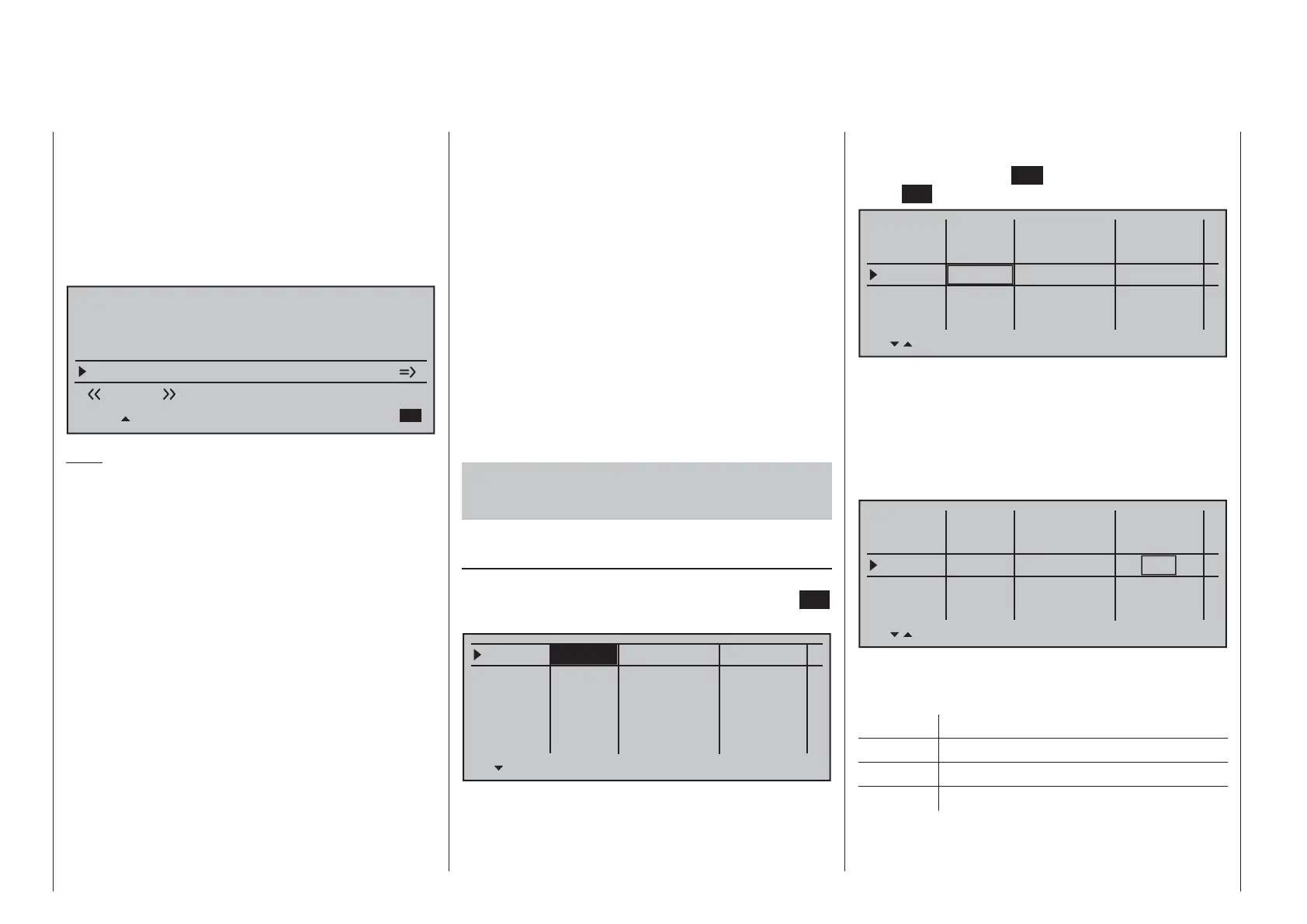

Two additional fl ight phases are now to be set

up below, each of which requires a somewhat

different fl ap position.

Therefore, switch to the menu …

»Phase settings« (page 142)

… and activate the assignment of phase names in

the "Name" column with a brief tap on the center

SET

key of the right touch pad:

Phase 1

Phase 2

Phase 3

Phase 4

Phase 5

0.1s

0.1s

0.1s

0.1s

0.1s

Name

Fl.ph.Tim. Sw. time

–

–

–

–

¾

Now give Phase 1 – the "Normal phase" – that is also

the phase which includes the previous settings, the

name "Normal", which you select from a list with the

selection keys.

Phase 2 is given the name "Thermal" and Phase 3 is

given the name "Speed". Now conclude the entries

with a brief tap on the

ESC key of the left touch pad

or the

SET key of the right touch pad:

Phase 1

Phase 2

Phase 3

Phase 4

Phase 5

0.1s

0.1s

0.1s

0.1s

0.1s

Name

Fl.ph.Tim. SW. time

–

–

–

–

¾

Normal

Thermal

Speed

Now move the marker frame beyond the "Fl.ph.Tim"

column to the right into the column "Sw. time" and set

a "switching time" from any other phase into the given

phase in order to avoid an abrupt phase change; in

other words to avoid erratic changes of fl ap positions.

Now try out different switching times. In this example

we have specifi ed 1 s in each case:

Phase 1

Phase 2

Phase 3

Phase 4

Phase 5

1.0s

1.0s

1.0s

0.1s

0.1s

Name

Fl.ph.tim. Sw. time

–

–

–

–

¾

Normal

Thermal

Speed

Whether or not one of the phases 1 … 8 currently has

an assigned switch and the state of the switch can be

seen in the "status" column at the far right.

Symbol Meaning

– No switch assigned

+ Phase can be called via switch

¾

Indicates the currently active phase

Since, except for phase 1, all other phases are still

designated with a "-" symbol, now switch in the

menu to …

Loading...

Loading...