144 Fixed Cycles: Pocket Milling / Stud Milling / Slot Milling

5.2 RECTANGULAR POCKET (Cycle 251, DIN/ISO: G251)

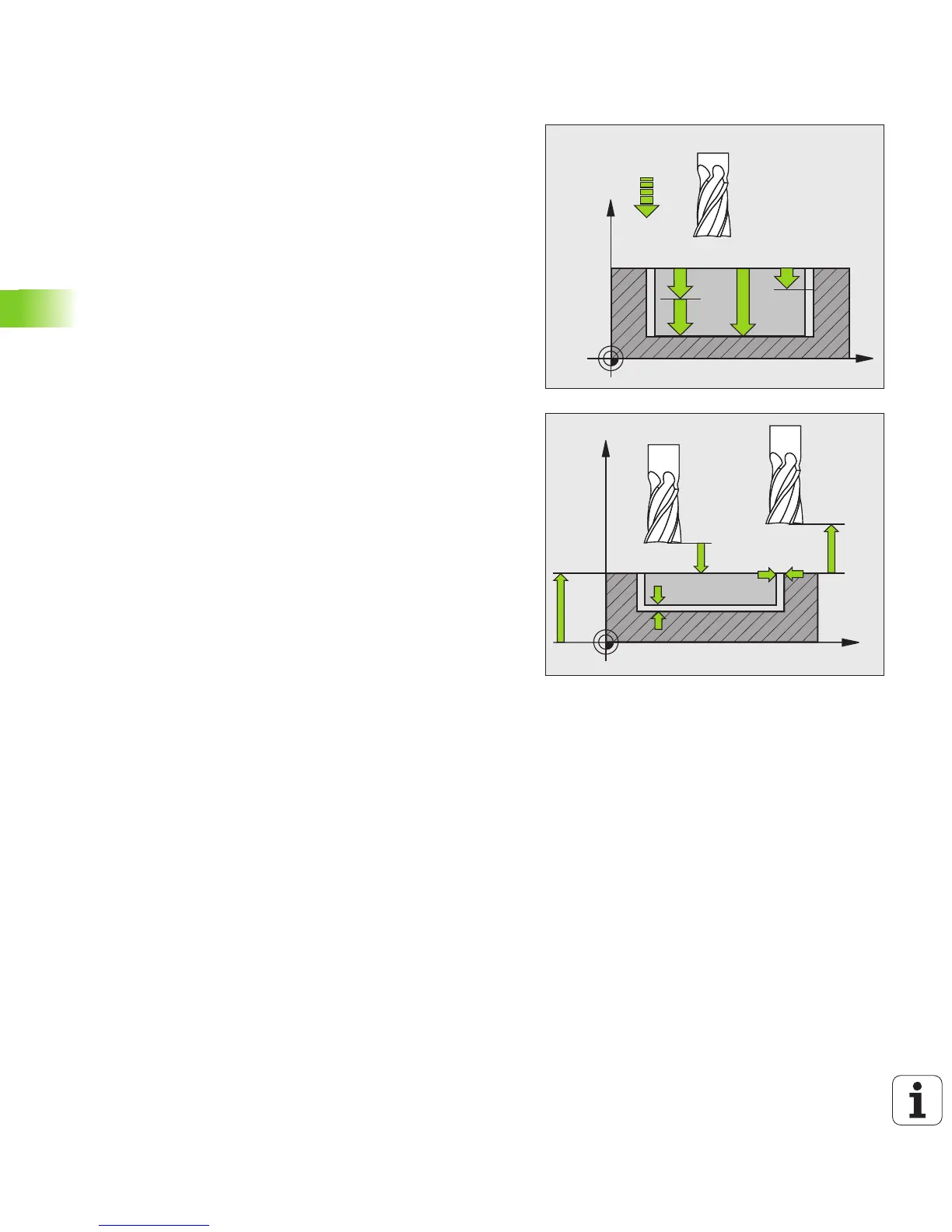

U Depth Q201 (incremental): Distance between

workpiece surface and bottom of pocket. Input range:

-99999.9999 to 99999.9999

U Plunging depth Q202 (incremental): Infeed per cut.

Enter a value greater than 0. Input range 0 to

99999.9999

U Finishing allowance for floor Q369 (incremental):

Finishing allowance in the tool axis. Input range 0 to

99999.9999

U Feed rate for plunging Q206: Traversing speed of

the tool while moving to depth in mm/min. Input

range: 0 to 99999.999; alternatively FAUTO, FU, FZ.

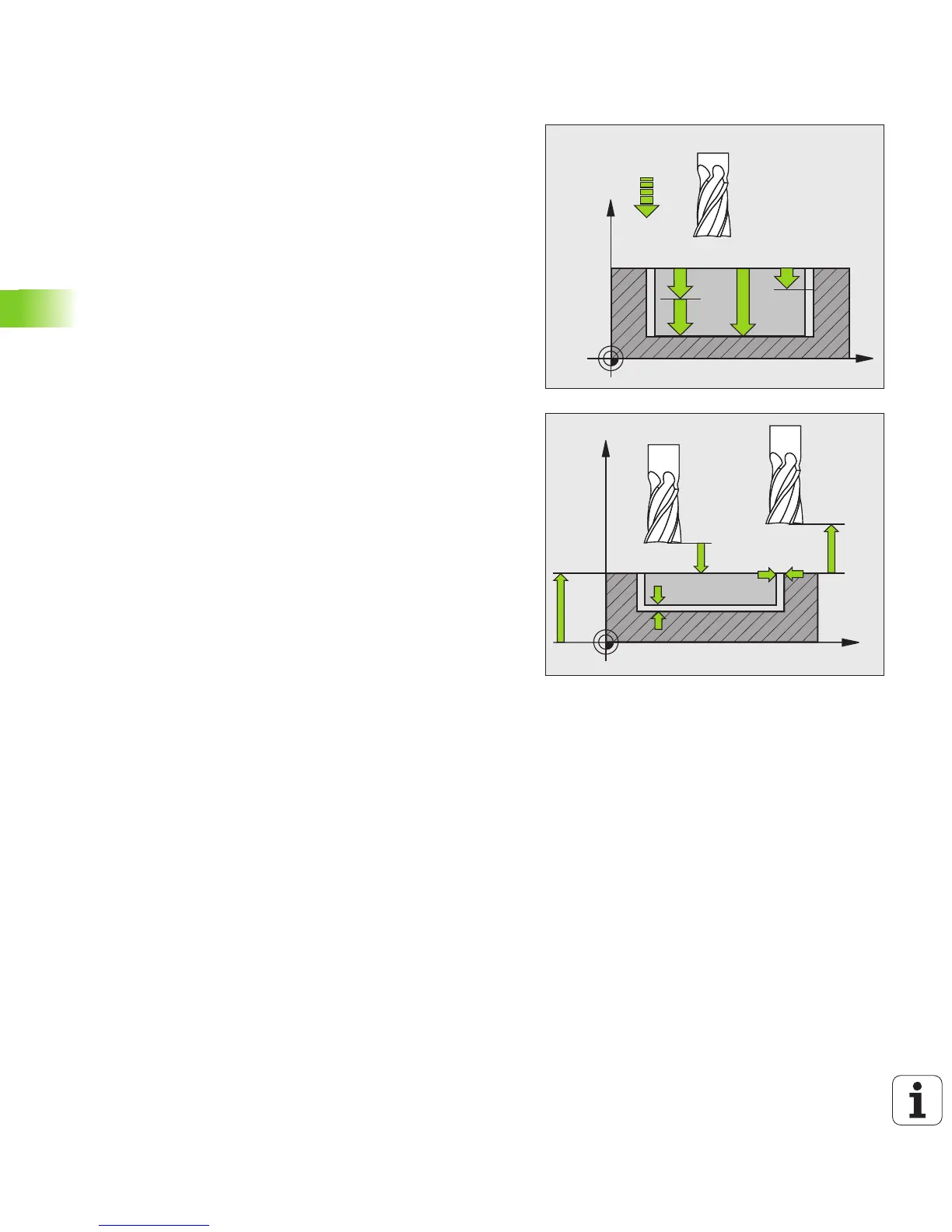

U Infeed for finishing Q338 (incremental): Infeed per

cut. Q338=0: Finishing in one infeed. Input range 0 to

99999.9999

U Setup clearance Q200 (incremental): Distance

between tool tip and workpiece surface. Input range

0 to 99999.9999, alternatively PREDEF

U Workpiece surface coordinate Q203 (absolute):

Absolute coordinate of the workpiece surface. Input

range -99999.9999 to 99999.9999

U 2nd setup clearance Q204 (incremental): Coordinate

in the spindle axis at which no collision between tool

and workpiece (fixtures) can occur. Input range 0 to

99999.9999, alternatively PREDEF

Loading...

Loading...