208 Fixed Cycles: Contour Pocket, Contour Trains

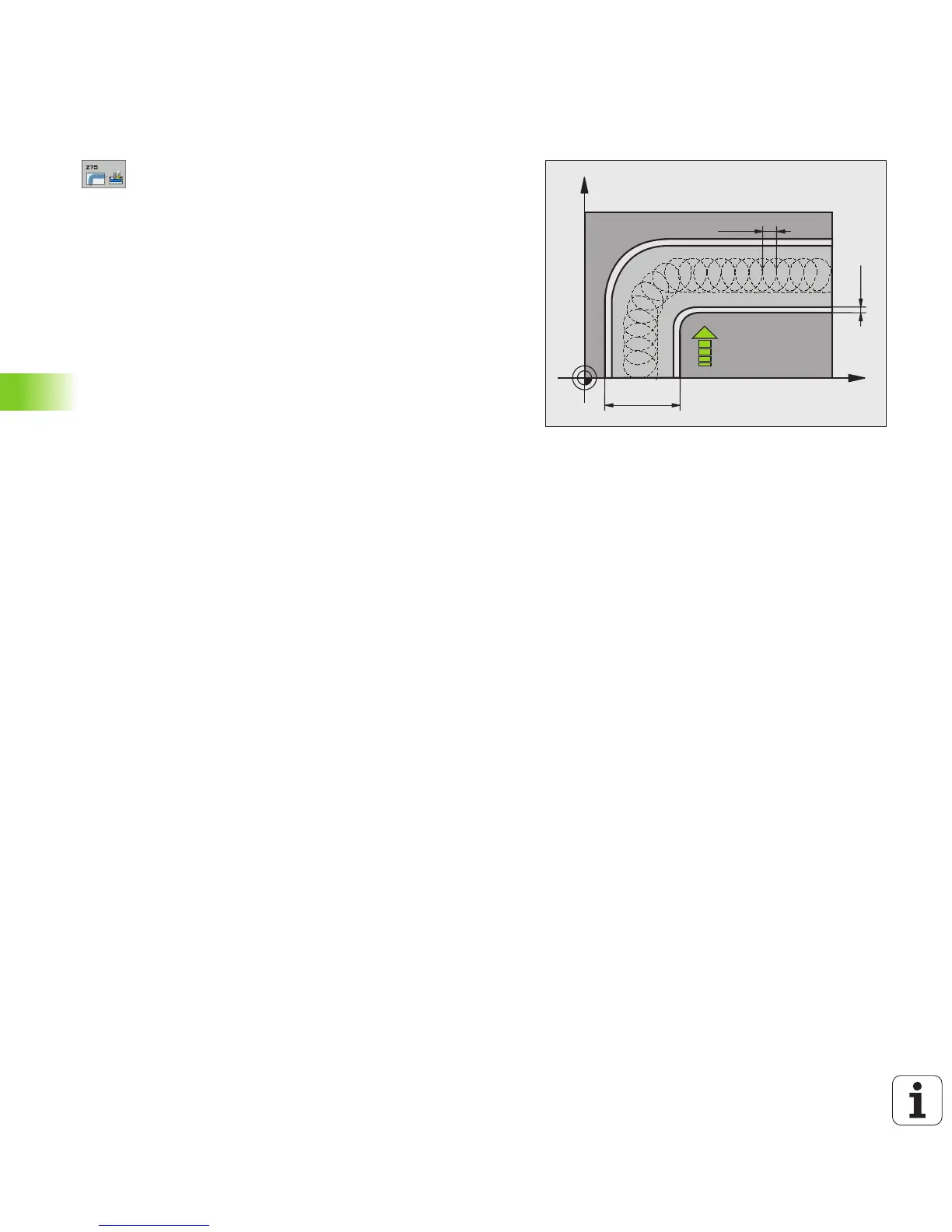

7.11 TROCHOIDAL SLOT (Cycle 275, DIN/ISO: G275)

Cycle parameters

U Machining operation (0/1/2) Q215: Define the

machining operation:

0: Roughing and finishing

1: Only roughing

2: Only finishing

The TNC also executes side finishing if the finishing

allowance (Q368) defined is 0.

U Slot width Q219: Enter the slot width; If you enter a

slot width that equals the tool diameter, the TNC will

only machine the contour outline. Input range 0 to

99999.9999

U Finishing allowance for side Q368 (incremental):

Finishing allowance in the working plane.

U Infeed per rev. Q436 absolute: Value by which the

TNC moves the tool in the machining direction per

revolution. Input range: 0 to 99999.9999

U Feed rate for milling Q207: Traversing speed of the

tool during milling in mm/min. Input range: 0 to

99999.999; alternatively FAUTO, FU, FZ

U Climb or up-cut Q351: Type of milling operation with

M3:

+1 = climb milling

–1 = up-cut milling

Alternatively PREDEF

Loading...

Loading...