260 Fixed Cycles: Multipass Milling

10.4 RULED SURFACE (Cycle 231, DIN/ISO: G231)

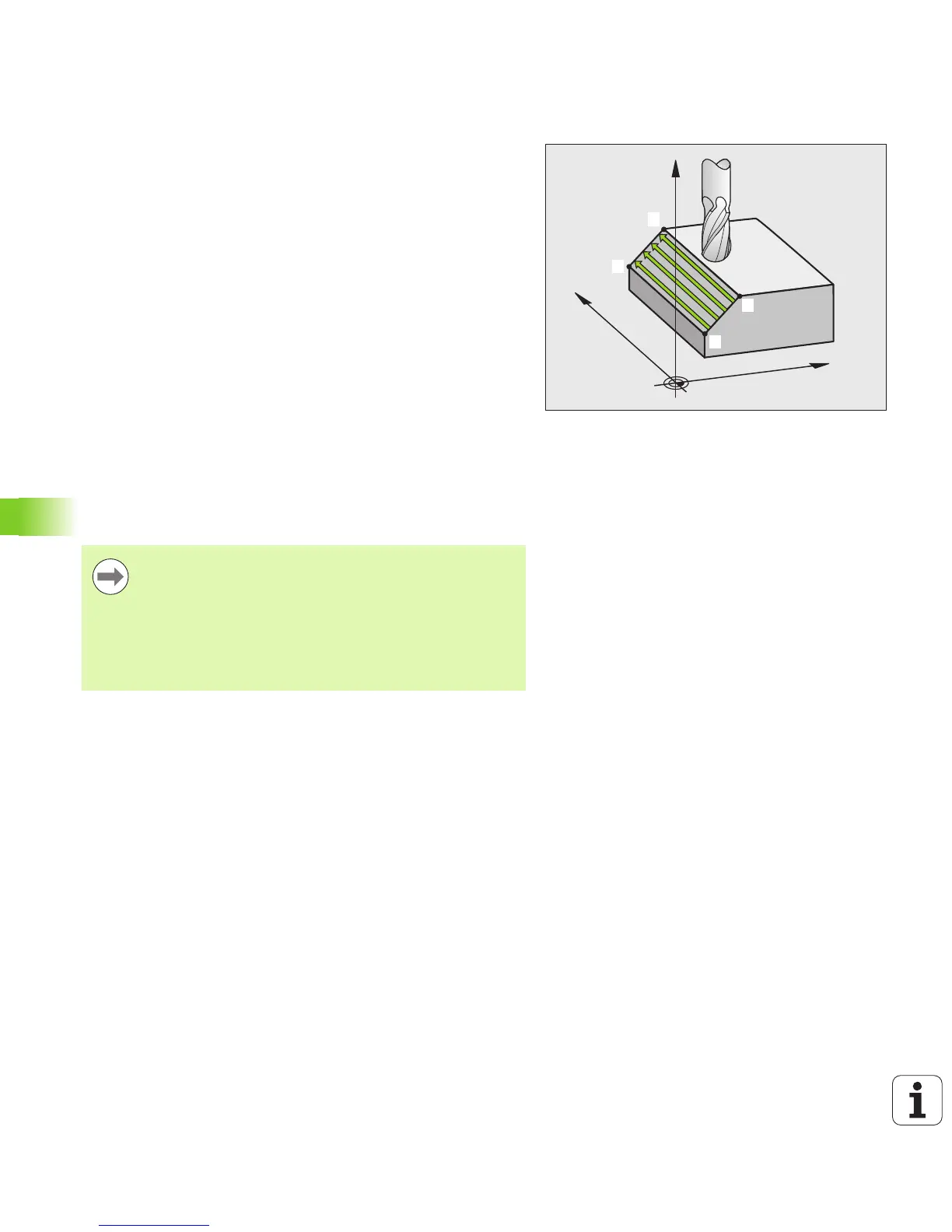

Cutting motion

The starting point, and therefore the milling direction, is selectable

because the TNC always moves from point 1 to point 2 and in the total

movement from point 1 / 2 to point 3 / 4. You can program point 1 at

any corner of the surface to be machined.

If you are using an end mill for the machining operation, you can

optimize the surface finish in the following ways:

A shaping cut (spindle axis coordinate of point 1 greater than

spindle-axis coordinate of point 2) for slightly inclined surfaces.

A drawing cut (spindle axis coordinate of point 1 smaller than

spindle-axis coordinate of point 2) for steep surfaces.

When milling twisted surfaces, program the main cutting direction

(from point 1 to point 2) parallel to the direction of the steeper

inclination.

If you are using a spherical cutter for the machining operation, you can

optimize the surface finish in the following way:

When milling twisted surfaces, program the main cutting direction

(from point 1 to point 2) perpendicular to the direction of the

steepest inclination.

Please note while programming:

From the current position, the TNC positions the tool in a

linear 3-D movement to the starting point 1. Pre-position

the tool in such a way that no collision between tool and

fixtures can occur.

The TNC moves the tool with radius compensation R0 to

the programmed positions.

If required, use a center-cut end mill (DIN 844).

Loading...

Loading...