Maintenance and Calibration

43

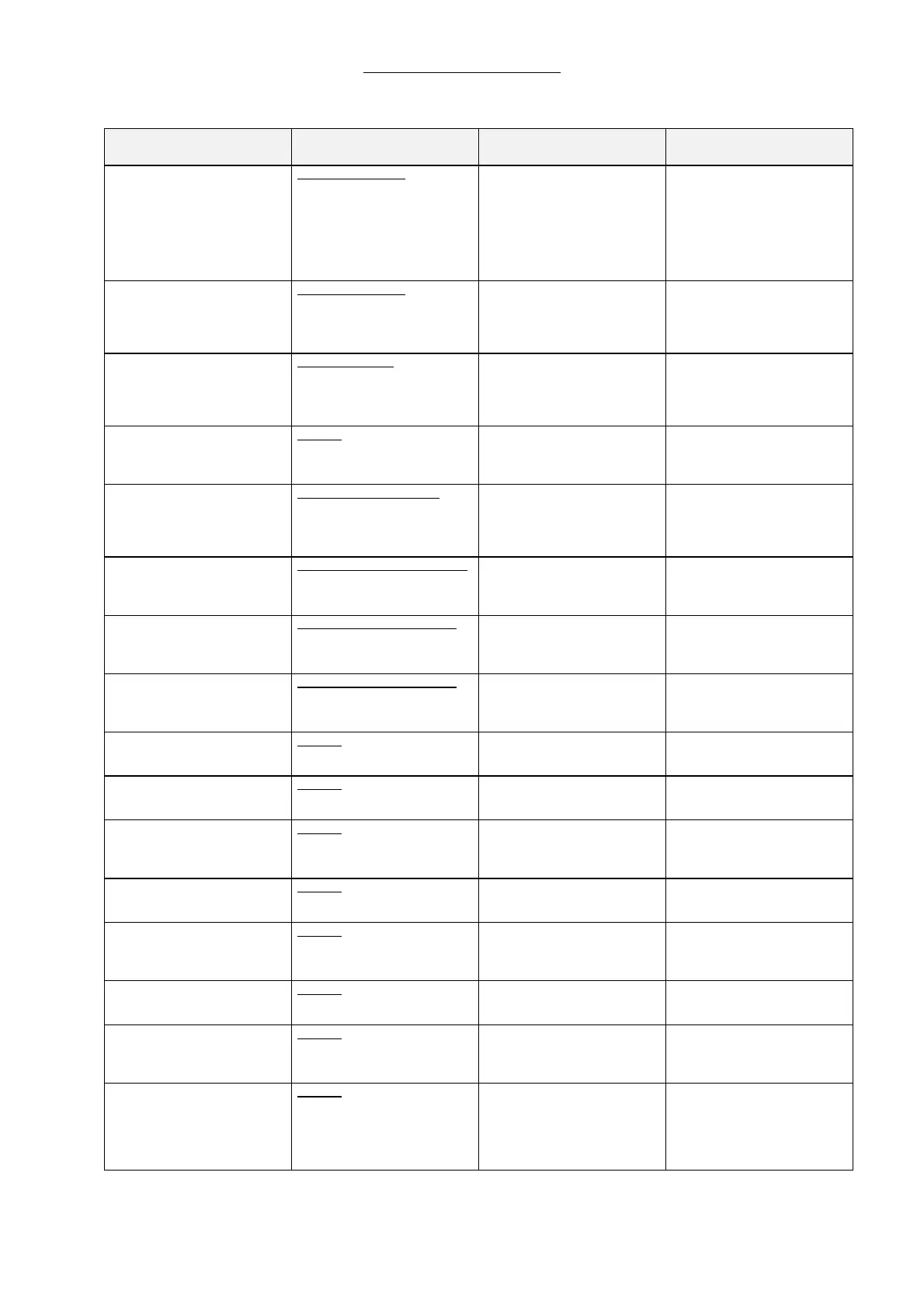

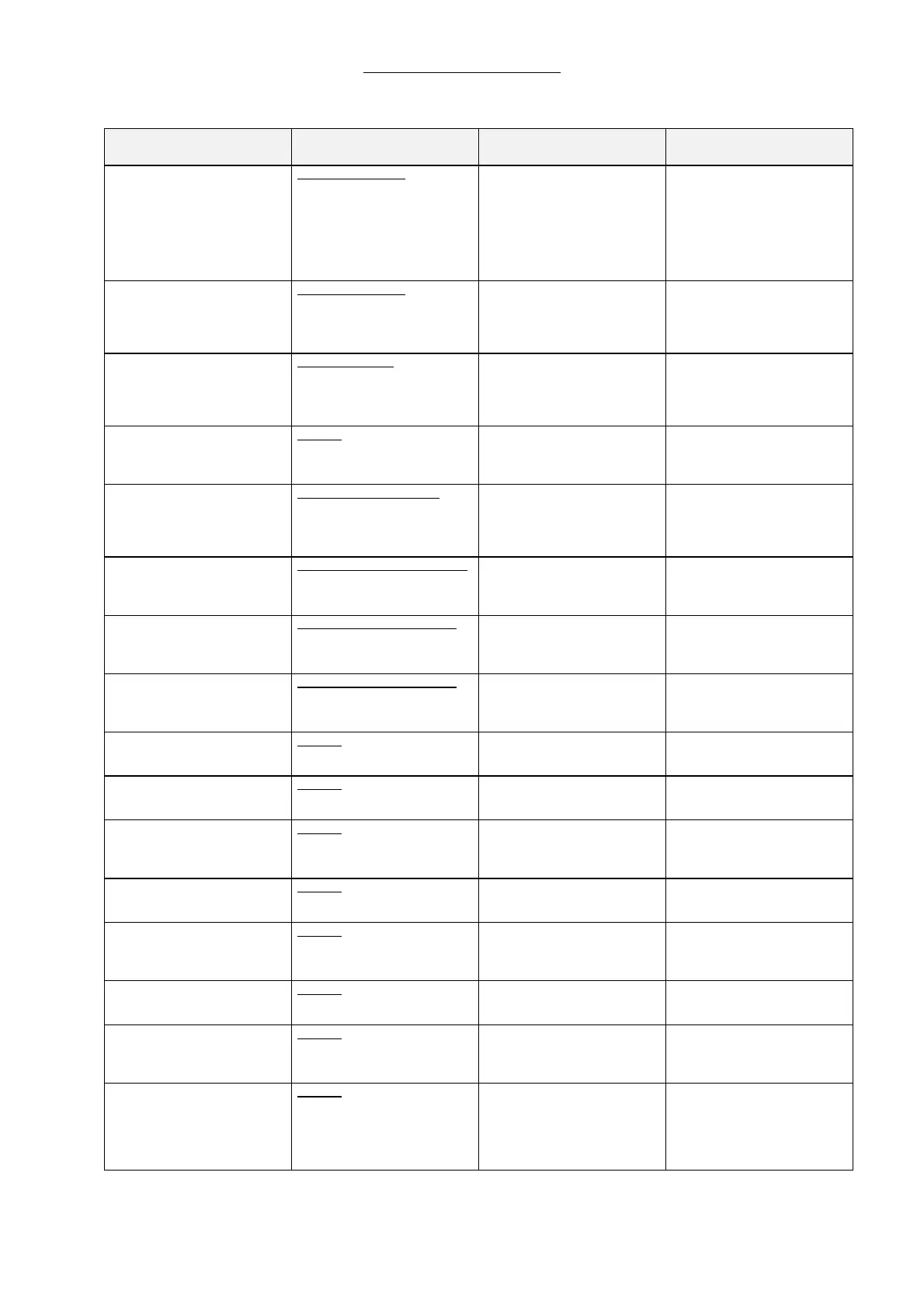

Display message Cause Corrective action User

Corrective action

Service technician

Valve Error: Use Manual

Ventilation

Call Service

AVM3-2 CMV/ PCV

The actual internal flow value

should be 0 during expiration

Finish the case with manual

ventilation;

Take the machine out of use;

Call Service

Recalibrate the proportional

valve, internal flow sensor and

the characteristic of the

proportional valve. If that does

not solve the problem,

exchange the

1. proportional valve

2. internal flow sensor

Calibrate Breathing

System

Perform Compliance Test

when convenient

AVM3-2 CMV, PCV

Difference between the set and

the detected state of each

solenoid valve for more than

200 ms

The intermitting tone is reset via

the mute button

(acknowledgement)

Reset the error message via

the compliance test

Check the correct voltage

supply for the solenoid vales. If

that does not solve the problem

exchange the according

solenoid valve

Pressure Reading out of

tolerance

Perform Compliance Test

when convenient

AVM3-1, AVM3-2

A difference between the two

pressure sensors of more than

10 mbar

The intermitting tone is reset via

the mute button

(acknowledgement)

Reset the error message via

the compliance test

Recalibrate the pressure

sensors and check the

according tubing. If that does

not solve the problem exchange

the module 2

No drive gas; please

check

AVM3-1

Monitoring of the pressure

switch for the driving gas

Ensure the driving gas supply,

restart the ventilation on

request.

Check the gas supply, the

correct tubing and the correct

connection and function of the

pressure switch

Flow/Volume Readings

not available

Replace Flow Sensor –

Call Service

AVM3-1 during ventilation

External flow sensor is broken

or short-circuited

The intermitting tone is reset via

the mute button

(acknowledgement)

Reset the error message via

the compliance test

Exchange the external flow

sensor

A P N E A

AVM3-1. Manual/ spontaneous

Within a period of 15 to 60

seconds a expiration cannot be

detected

Create expiration Ensure the correct function of

the circle system

Breathing Circuit

Disconnect

AVM3-1 CMV, (S)CMV, PCV

The peak pressure PPEAK is

lower than 0.5 mbar and lower

then the set pressure limit Pmin

Create a pressure increase in

the inspiration phase

Ensure the correct function of

the circle system and the

correct electrical and pneumatic

function of the solenoid valves

PEEP greater than Pmin

AVM3-1 CMV, (S)CMV, PCV

The end expiratory pressure is

greater than the set pressure

limit Pmin

Lower the end expiratory

pressure or raise the pressure

limit Pmin

Check the correct position and

function of the APL valve.

Ensure the correct function of

the circle system

FiO2 lower than FiO2

min

AVM3-1

The measured O2 value is

lower than the set O2min limit

Increase the O2 value or raise

the limit O2min

Recalibrate and check the

correct function of the O

2

cell.

Exchange if necessary

Tidal Volume lower than

V

TE

AVM3-1

The measured V

TE

value is

lower than the set V

TE

min limit

Increase the V

TE

value or raise

the limit V

TE

min

Peak pressure greater

than alarm limit

AVM3-1

The measured Ppeak value is

greater than or equal to the set

Pmax limit

Decrease the Ppeak value or

raise the limit Pmax

Peak pressure below

alarm limit

AVM3-1

The measured Ppeak value is

lower than the set Pmin limit

Increase the Ppeak value or

lower the limit Pmin

Minute Volume below

alarm limit

AVM3-1

The calculated M.Vol value is

lower than the set M.Vol min

limit

Increase the ventilation rate or

the V

TE

value or lower the limit

Pmin

PEEP greater than

PEEP-Setting

AVM3-1

The measured PEEP value is 5

mbar higher than the set PEEP

Decrease the PEEP value or

raise the set PEEP

Check the correct position and

function of the APL valve

FiO2 greater than FiO2

alarm limit

AVM3-1

The measured FiO2 value is

greater than the set FiO2max

limit

Decrease the FiO2 value or

raise the set FiO2max limit

Re-calibrate the O2 sensor

Check Vent Dial position

AVM3-1

The selector switch position is

monitored An invalid position

must be eliminated within two

seconds. After this the alarm

message appears.

The last detected valid position

is maintained until a new valid

position is detected, then the

message disappears

1. Check the correct function of

the Vent Dial

Loading...

Loading...