Preventive Maintenance

64

4 Verify O2 pressure loss alarm (whistle) and N2O cutoff.

a Ventilate a test lung in the CMV mode.

b Set the AIR/N

2

O switch to N

2

O

c Flow 1 l/min O

2

and 1 l/min N

2

O using the flow meter spindle valves.

d Interrupt the O

2

supply to the Modular

+

.

e Verify the O

2

pressure loss alarm whistle for approximately 7 seconds, and the flow of nitrous

oxide lowers to 0 l/min. If O

2

is the ventilator drive gas, an electrical alarm and message will

also activate.

f Verify at the same time, Air is available by adjusting the AIR spindle valve. AIR flow will be

available regardless of the position of the AIR/N

2

O switch position. Air flow can be increased

by rotating the Air flow spindle.

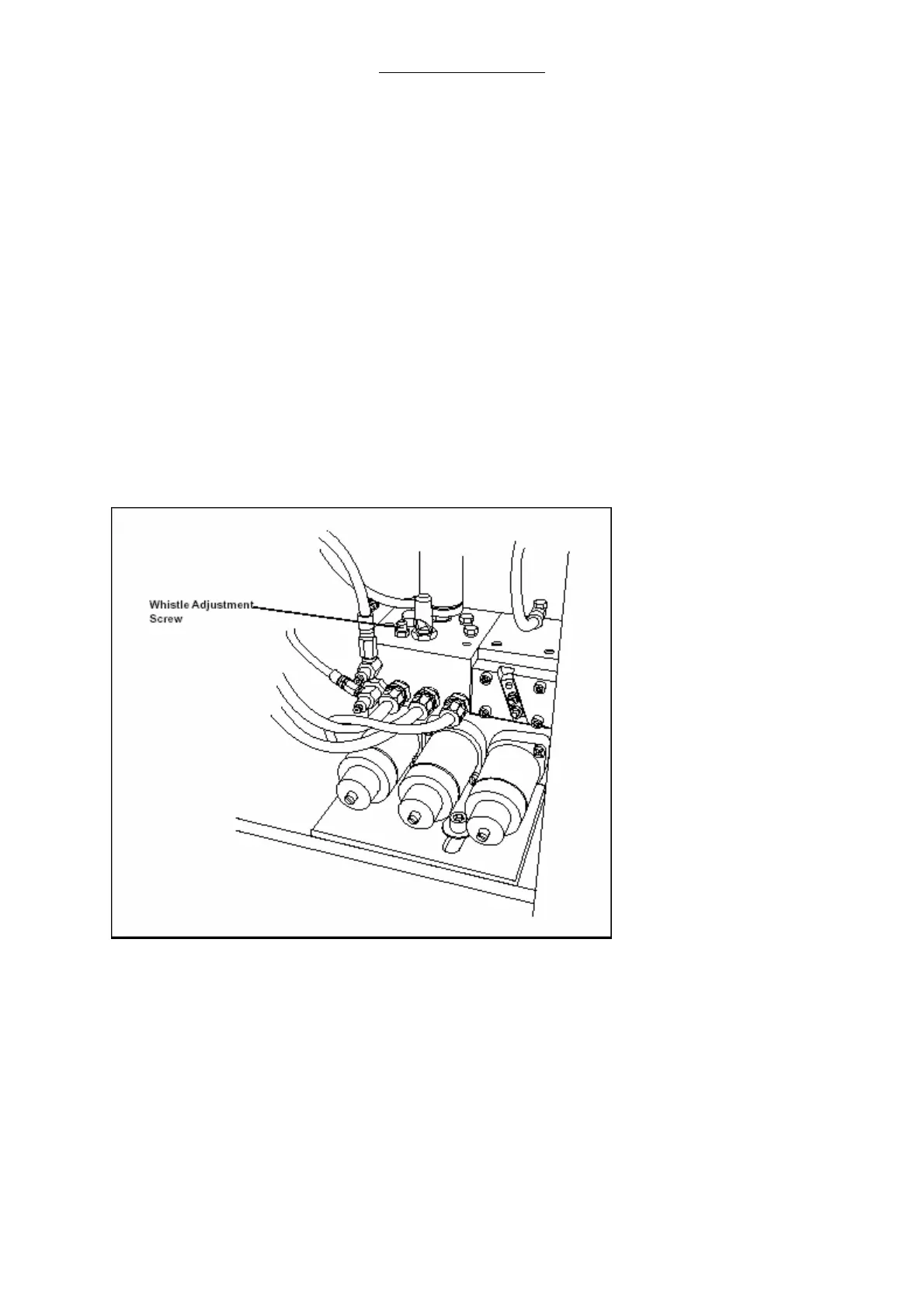

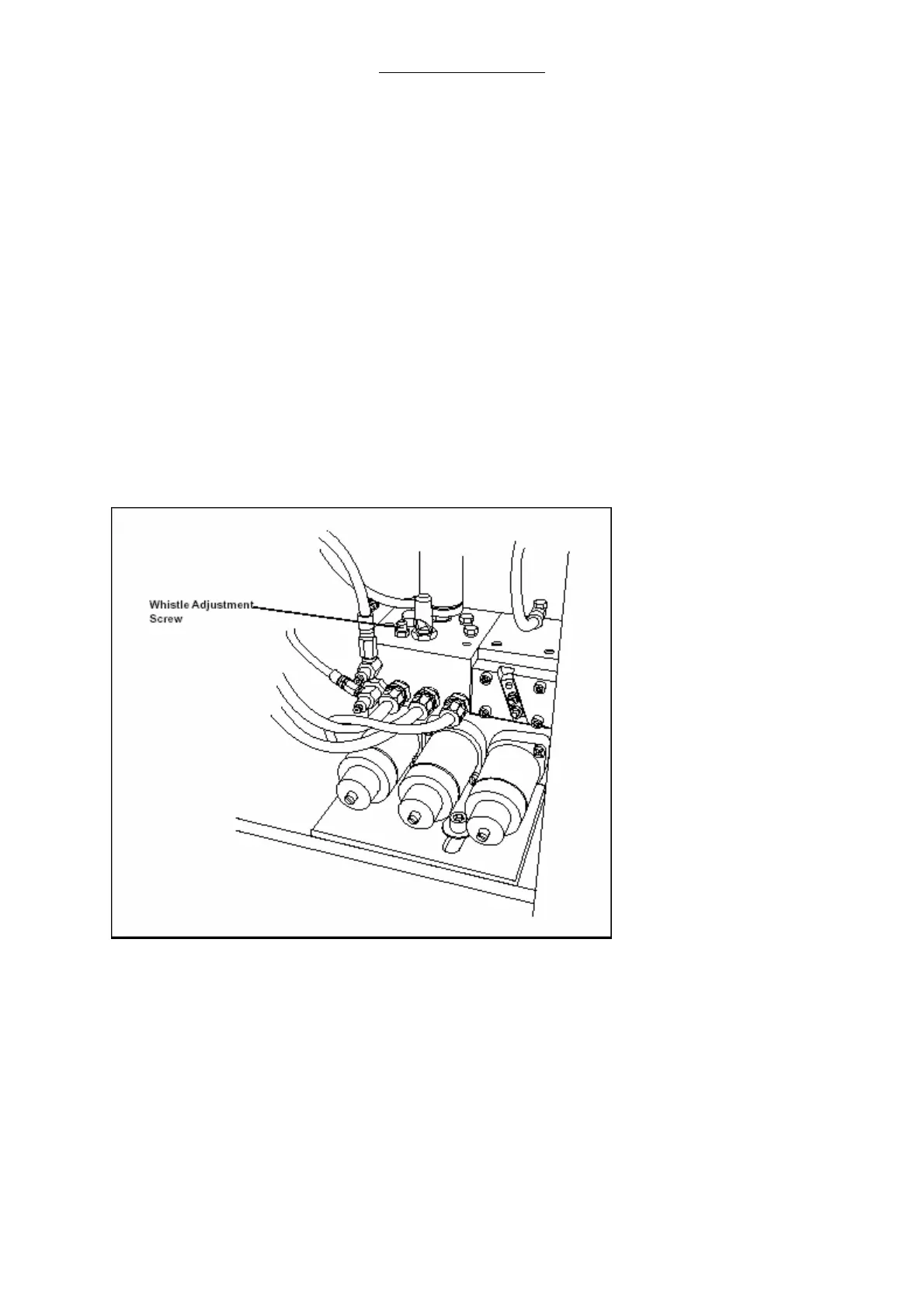

g If necessary, adjust the time and loudness level of the O2 deficiency whistle by setting the

screw adjustment next to the Whistle reservoir.

Fig. 21 O2 Whistle adjustment (appearance may differ due to different configuration options)

5 Verify line voltage alarm.

a Interrupt AC line voltage while the respirator unit is in manual/spontaneous or automatic

ventilation mode.

b Verify that the line power alarm sounds and that the AC connector icon appears on the

display. The alarm is reset when reconnecting the line power supply.

c Verify the battery icon appears on the screen after AC reconnection. This indicates battery

charging.

Loading...

Loading...