Maintenance and Calibration

46

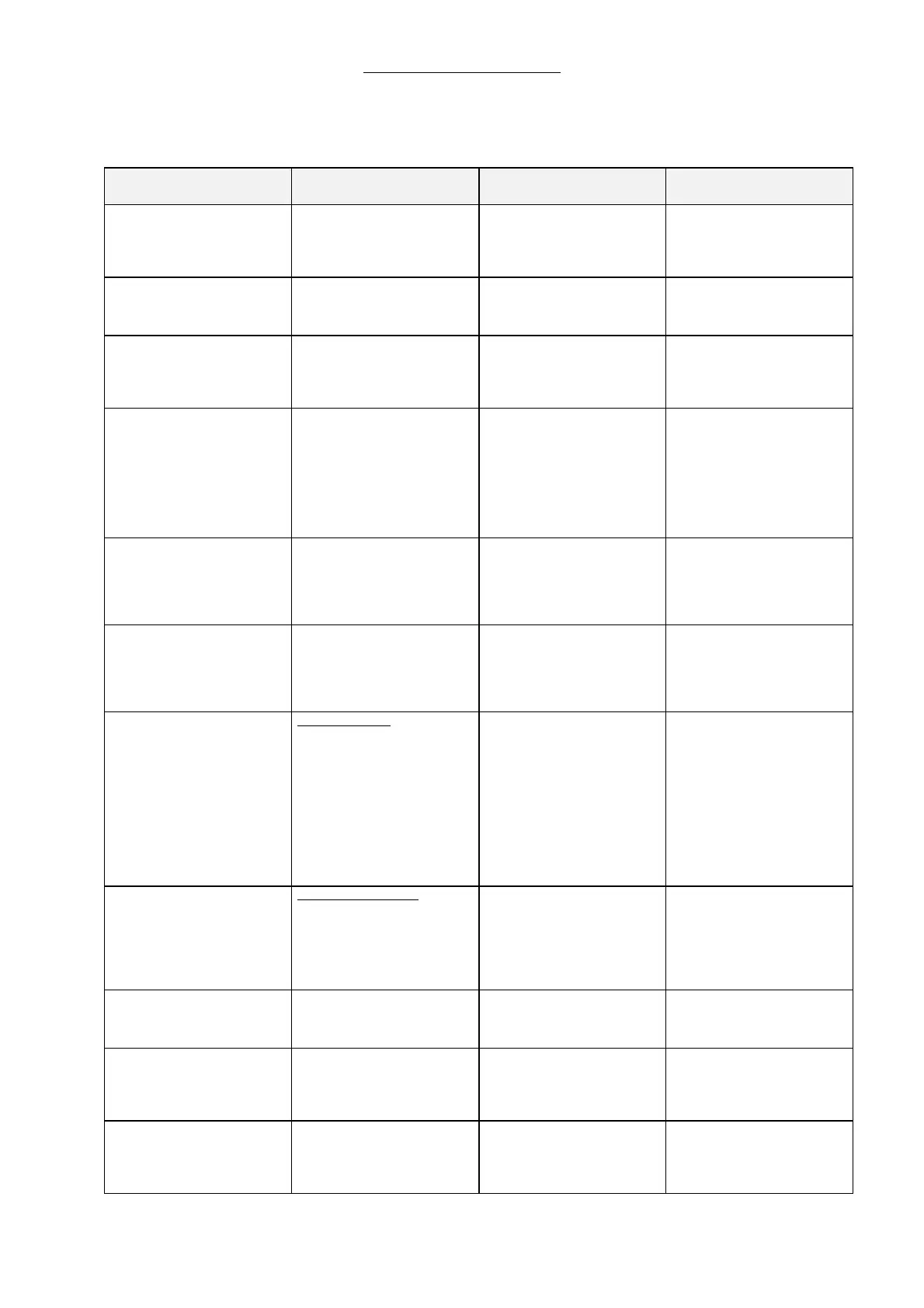

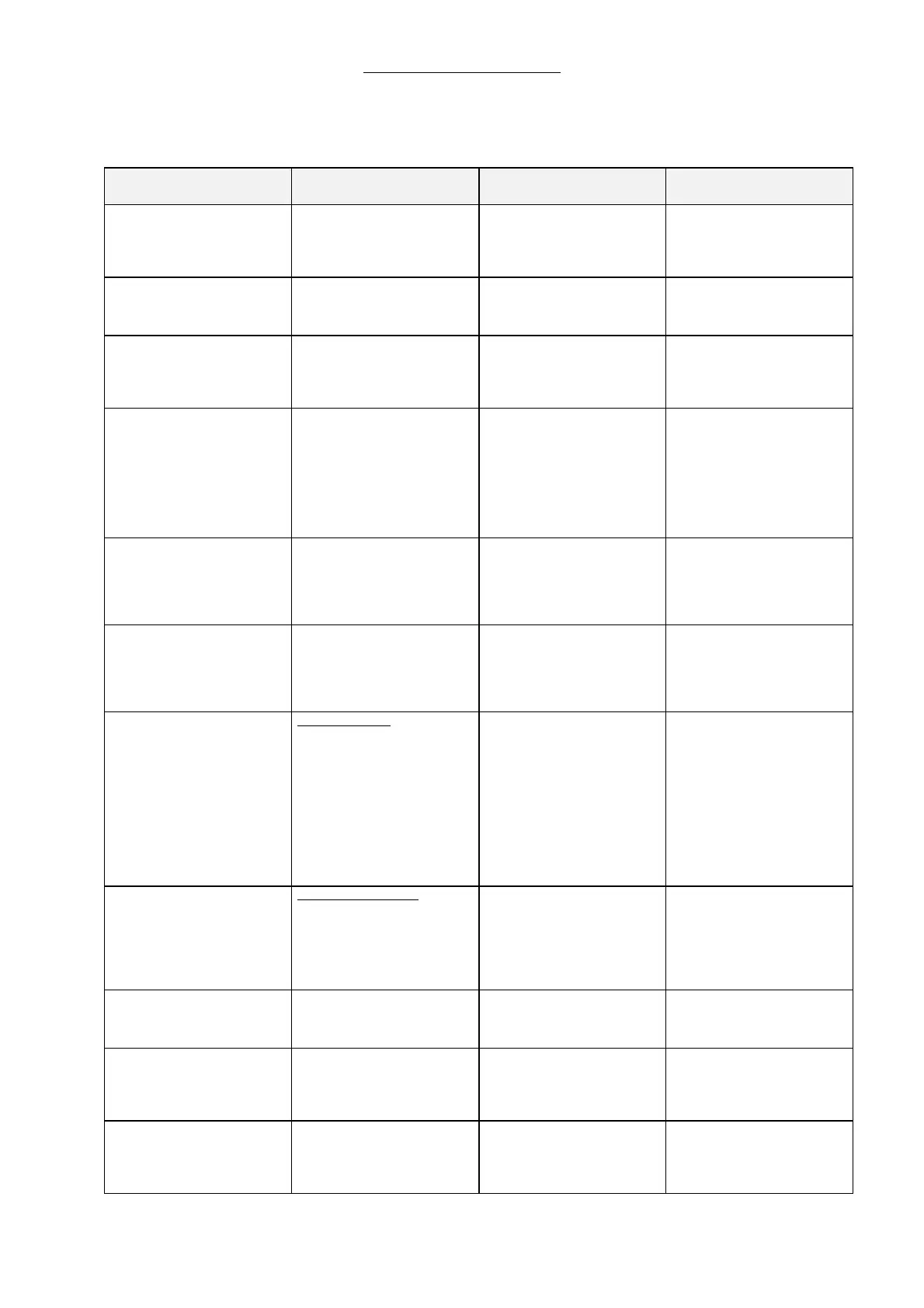

3.4.2 Alarm messages during the compliance test, leak test and O2 calibration

Display message Cause Corrective action User

Corrective action

Service technician

System Resistance

too high

AVM 3-2

If with in 1 sec. after a flow of

12 l/min has been generated, a

pressure increase of 10 mbar is

measured

Repeat the compliance test Check the breathing circuit for

obstructions

Leak rate too high

AVM 3-2

If after 10 mbar have been

reached, 40 mbar are not

reached within 2s

Troubleshoot the breathing

circuit for leakages

Troubleshoot the breathing

circuit for leakages

Compliance out of range

AVM 3-2

The measured compliance has

to be between 2.0 and 9.9

Replace bacteria filter and

breathing circuit. Use the

Compliance test in Standby /

OPTIONS to retest. If all else

fails call Service.

Replace bacteria filter and

breathing circuit. Check the

complete breathing system for

obstructions.

System Error

Cal Required

Call Service

AVM 3-2

Data for parameter or alarm

limit settings was not saved

correctly, the data exchange

between the ventilator modules

and on-screen display is faulty

or the startup test for Internal

circuit EEPROM has failed.

Retry function. Reboot

machine. If all else fails call

Service.

Recalibrate the system. If this

fails, exchange the module 2

processor board

Check Diaphragm Valves

AVM 3-2

The PV closes after 40mbar

has been reached. If after this a

pressure increase of 4 mbar

takes place within 4 s

Remove the Breathing circuit

from the Docking Station and

check the Decoupling and

Expiratory valves for intact

membranes. Replace as

required or call Service.

Remove the Breathing circuit

from the Docking Station and

check the Decoupling and

Expiratory valves for intact

membranes. Replace as

required

Pressure Reading out of

tolerance

Perform Compliance Test

when convenient

If the pressure sensors

measure a difference greater

than 3 mbar during the offset

comparison, even though the

system is pressure relieved.

Take the machine out of use;

Call Service

Recalibrate the pressure

sensors and check the

according tubing. If that does

not solve the problem exchange

the module 2

Flow Error:

Use Manual Ventilation

Call Service

Compliance Test

• When during the

offset calibration a flow of

greater than 3 L/min is

detected

• During the

compliance test a flow of

12 L/min is delivered

through the prop. valve. If

the delivered flow is out

of tolerance

Flow Sensor Error

Take the machine out of use;

Call Service

Recalibrate the proportional

valve, internal flow sensor and

the characteristic of the

proportional valve. If that does

not solve the problem,

exchange the

1. proportional valve

2. internal flow sensor

Flow/Volume Readings

not available

Replace Flow Sensor -

Call Service

AVM3-2 Pressure test

• Cannot be set to zero via

the analogue output

• Set DAC value greater

than 1,83V

• The amplifier circuit is not

working correctly

Retry function. Reboot

machine. If else fails call

service

Exchange the external flow

sensor

System Error

Cal Required - Call

Service

EEPROM is checked during the

start up and during the sensor

test for CRC errors

Take the machine out of use;

Call Service

Recalibrate the complete

system. If that does not solve

the problem exchange the

module 2

Calibrate Breathing

System

Perform Compliance Test

The checking of the solenoid

valves failed

Retry function. Reboot

machine. If else fails call

service

Check the correct voltage

supply for the solenoid vales. If

that does not solve the problem

exchange the according

solenoid valve

Insert Breathing system

The system does not detect a

signal from the stop switch in

the docking station

Insert Breathing system, else

call service

Test the correct function of the

stop switch in the service mode.

If the function ids OK, readjust

it’s positioning. If the function is

faulty, exchange the stop switch

Loading...

Loading...