H E Y E R P a s i t h e c

Rev. 0.2 Draft – 12/09 HEYER Pasithec, Operator’s manual 47 / 106

Follow the steps to test the flow control:

1. Connect the pipeline gas supply or open the cylinder valves slowly.

2. Turn counter-clockwise O

2

, N

2

O, AIR flow control valve.

Make sure no gas flows in the flowmeter.

3. Turn on the Pneumatic and Electronic Switch and choose the “O

2

+N

2

O” option.

4. Do not use this system if the battery is not fully charged or other ventilator failure alarm occurs.

•

Step 5 and step 6 are only applicable for the N

2

O system test.

WARNING: During Step 5 and Step 6, continue to use the link systems.

Only adjust control test (N

2

O in step 5 and O

2

in step 6).

Adjust flow according to order (N

2

O first, O

2

second).

If adjustable range is exceeded, adjust flow control and perform this step

again.

5. To test the flow increase of the link system:

•

Turn the N

2

O and O

2

flow control clockwise to the end.

•

Turn the N

2

O flow control slowly counterclockwise.

•

Set the N

2

O flow control to the rate described in the following table. The O

2

flow must be

higher than the minimum flow limit.

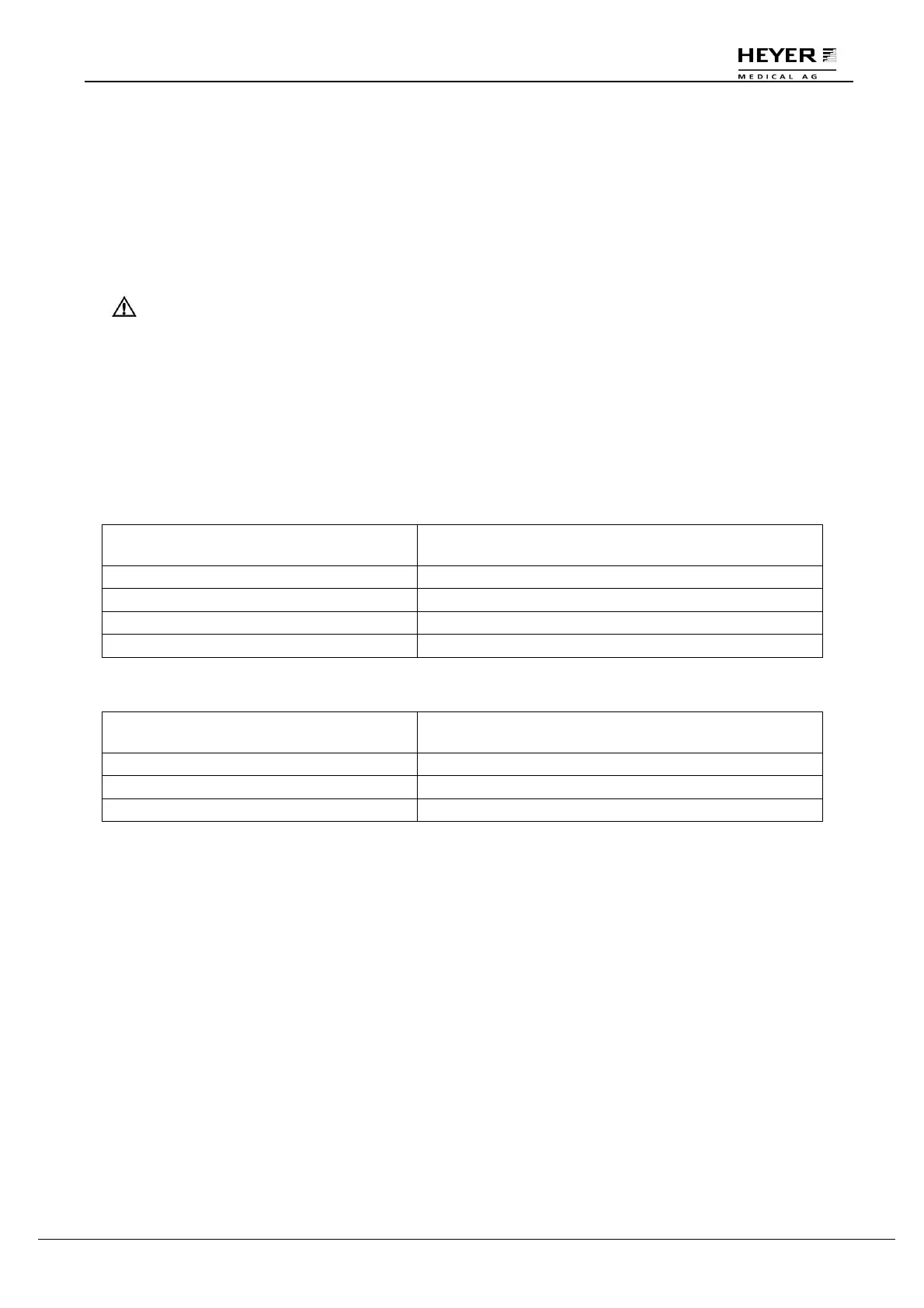

N

2

O flow

(liters per minute):

O

2

flow (must be higher than the minimum flow)

(liters per minute):

1.5 0.5

3 1

6 2

9 3

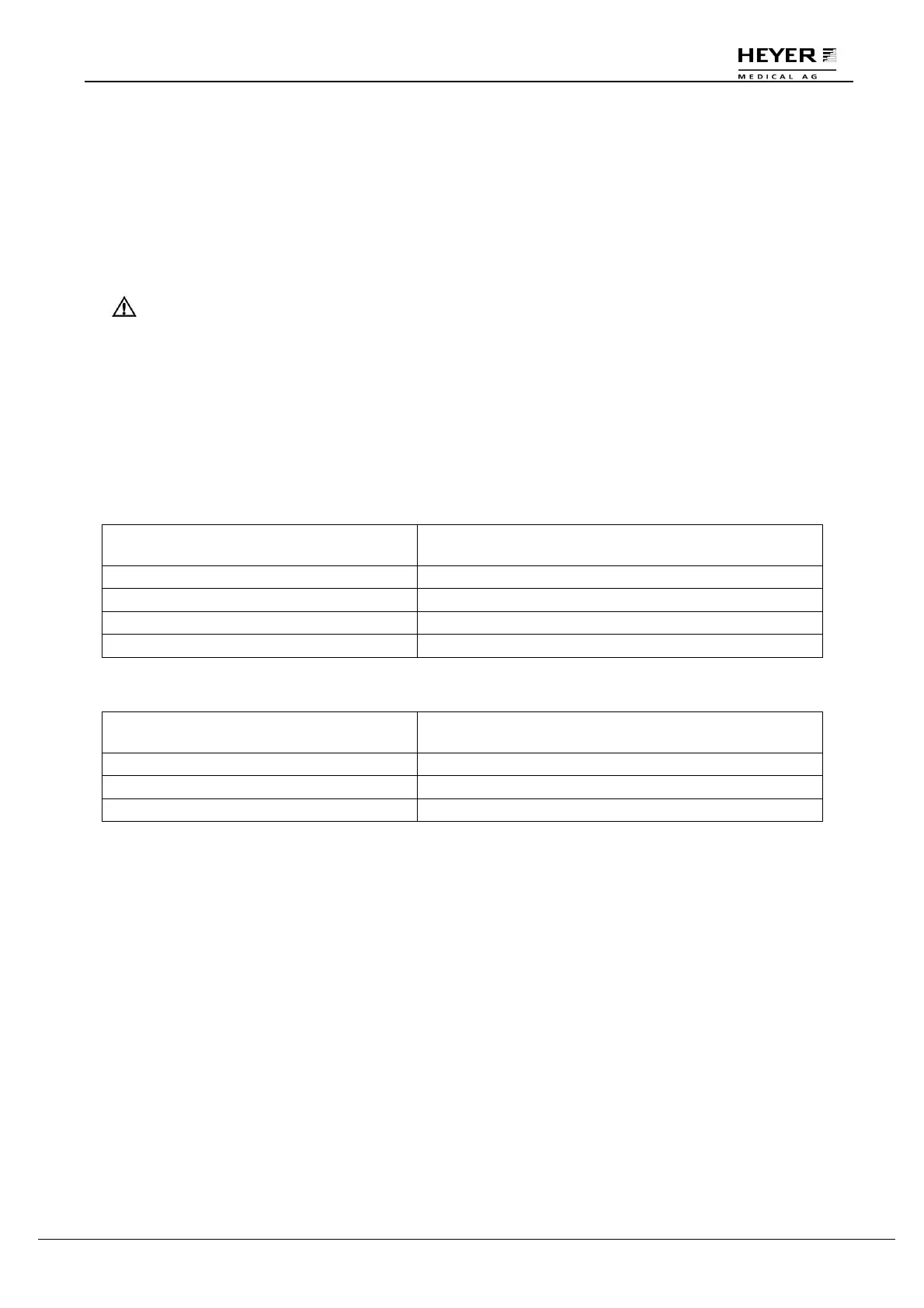

6. Test the function of the link system when flow is reduced.

N

2

O flow

(liters per minute):

O

2

flow (must be higher than the minimum flow)

(liters per minute):

6.0 2.0

3.0 1.0

0.6 0.2

7. Adjust full flow of all gases to ensure that the flowmeter float moves smoothly.

8. Shut off the oxygen supply by closing the oxygen cylinder valve or by disconnecting the oxygen

pipeline supply.

9. When using the flow control:

•

As pressure decreases, the oxygen-supply failure alarm must continuously sound.

•

Disconnect the flow of nitrous oxide and oxygen to be sure that the oxygen flow will be the

last to stop.

•

If the oxygen is the driving gas of the ventilator, the oxygen-supply failure alarm must

continuously sound.

10. Turn all flow control valves completely clockwise to close.

11. Change the Pneumatic and Electronic Switch to “O

2

+AIR”.

12. Adjust full flow of O

2

and AIR to ensure that the flowmeter float moves smoothly.

13. Adjust the knob of the N

2

O flowmeter and ensure that there is no gas in the flowmeter.

14. Turn off the Pneumatic and Electronic Switch.

Loading...

Loading...