D2 Drive User Guide v1.8 2. Specifications

HIWIN Mikrosystem Corp. 11

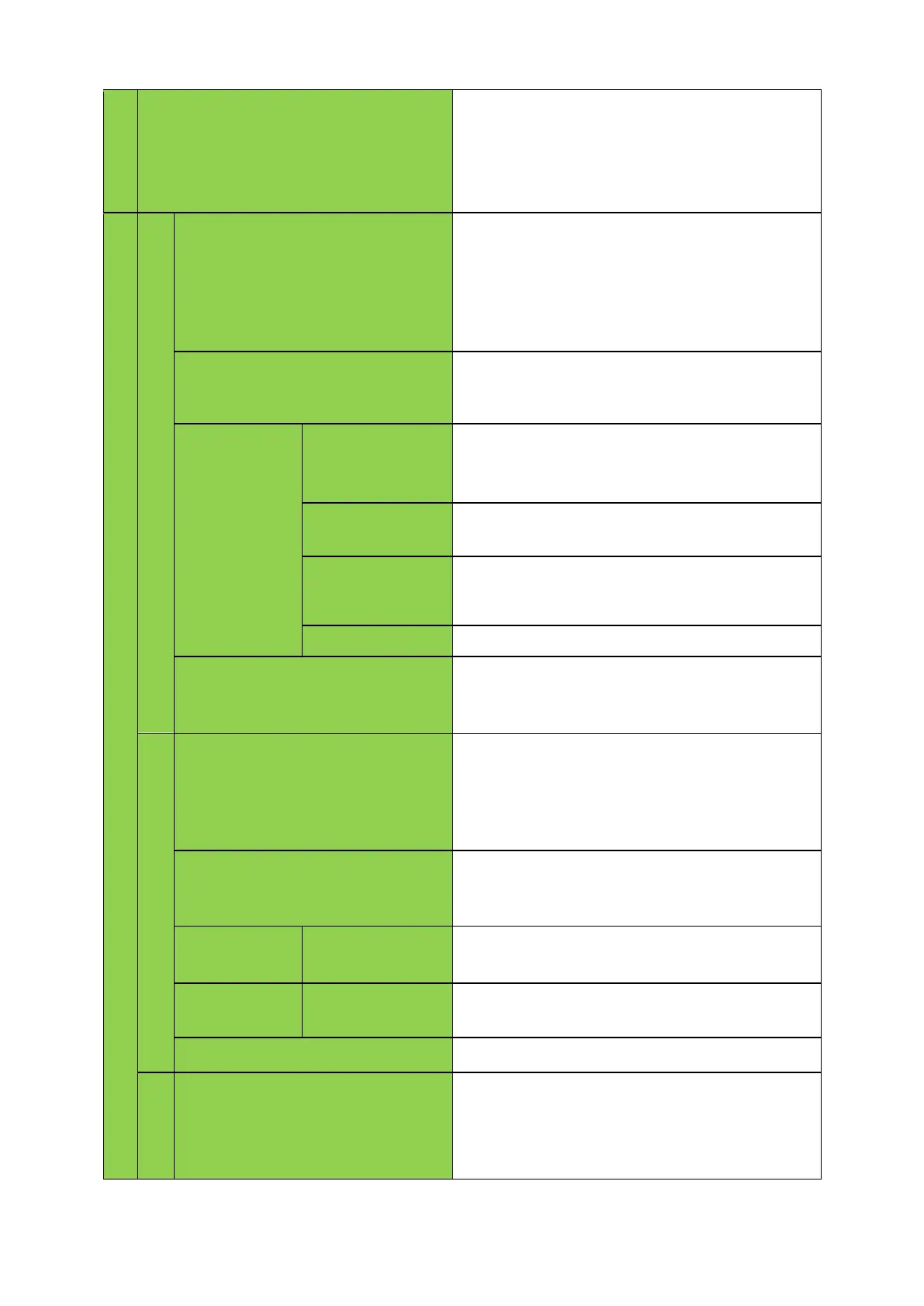

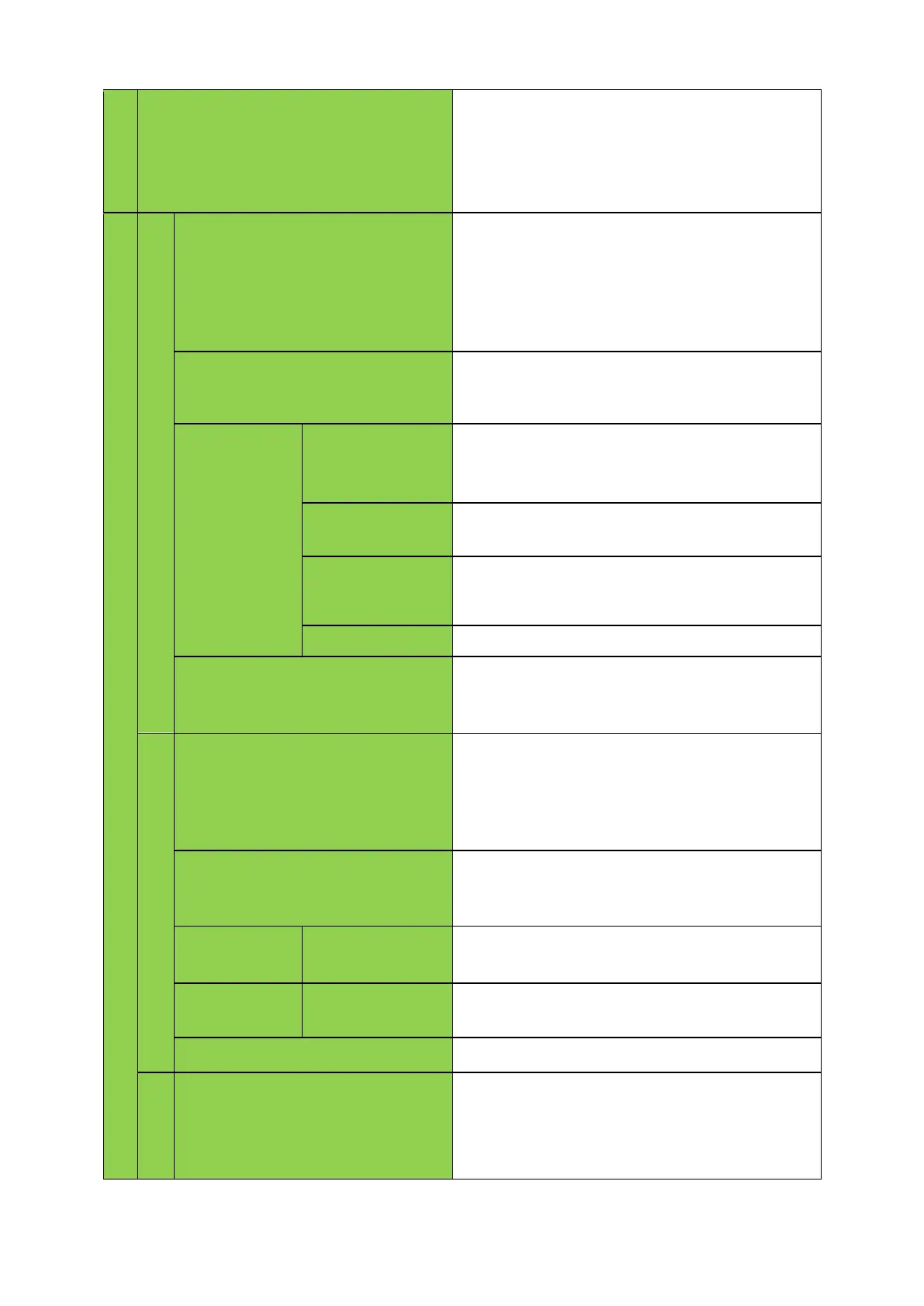

Switchable control modes

(1) Position control;

(2) Velocity control;

(3) Torque control ;

(4) Position/velocity control;

(5) Position/torque control ;

(6) Velocity/torque control;

(1) Inhibit pulse command;

(2) Axis enable;

(3) Switch between primary and secondary CG;

(4) Electronic gear selection;

(5) Left limit switch;

(6) Switch between primary and secondary mode;

(7) Clear error;

(8) Right limit switch, etc.

(1) Servo ready;

(2) Errors;

(3) In-position;

(4) Zero speed detected, etc.

Maximum input

pulse frequency

Photo-coupler interface (single-ended input): 500 Kpps;

Line driver interface (differential input): 4 Mpps (16M

count/s with AqB).

Signal format of

input pulse

(1) Pulse/direction (Pulse/Dir);

(2) Pulse up/pulse down (CW/CCW);

(3) Quadrature (AqB).

Electronic gear

(Division/

Multiplication of

command pulse)

Gear ratio: pulses/counts

Pulses: 1 - 2,147,483,647; counts: 1 – 2,147,483,647.

Smooth factor: 1 - 500 (0: no smoothing filter)

Vibration suppression feature (VSF)

VSF can remove the vibration frequency that occurs

during movement. It can reduce the vibration caused by

the system’s structure and improve the machine’s

productivity.

(1) Zero speed clamp;

(2) Axis enable;

(3) Switch between primary and secondary CG

(4) Left limit switch

(5) Switch between primary and secondary mode

(6) Clear error

(7) Right limit switch, etc.

(1) Servo ready;

(2) Errors;

(3) In-velocity;

(4) Zero speed detection, etc.

Velocity commands can be provided by the duty cycle of

PWM input. Parameters are used to set the scale and

command direction.

Velocity command can be provided by the analog voltage.

Parameters are used to set the scale and command

direction.

The input of zero speed clamp is possible.

(1) Axis enable;

(2) Switch between primary and secondary CG;

(3) Left limit switch;

(4) Switch between primary and secondary mode;

(5) Clear error;

(6) Right limit switch, etc.

Loading...

Loading...