D2 Drive User Guide v1.8 8. Protection Function

HIWIN Mikrosystem Corp. 237

8.2. Position and velocity errors protection

8.2.1. Position error limit

There is a position error in the servo control. The position error is usually larger when the

motor moves. Moreover, some external factors may also cause that the position error

becomes abnormally large, such as that bearings or linear guideways on the mechanism have

a high friction due to the lack of lubricators, the winding or cable tray is too tight, foreign

objects invades on the motor travel, the motor hits the abnormal object or hard stop, the

position encoder is abnormal or interfered, and other conditions. In order to avoid all kinds of

anomalies leading the position error too big, D2 drive has a “Error windows”. When the

position error is over this “Error windows”, the drive will generate an error message of

“Position error too big”, start the emergency stop procedure, send the brake signal, and

disable the motor.

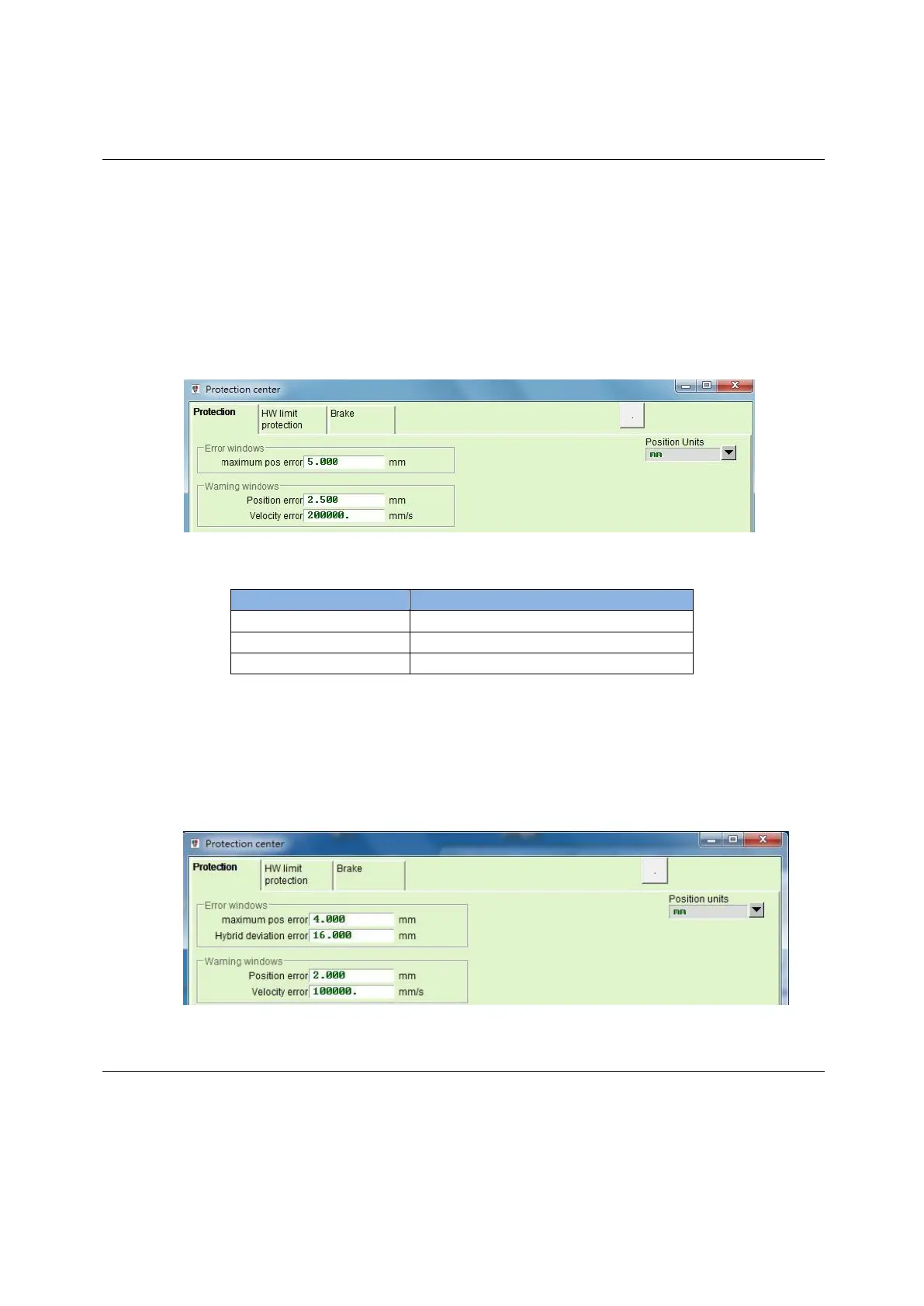

Fig. 8-4

Table 8-3

Maximum position error limit

Position error warning value

Velocity error warning value

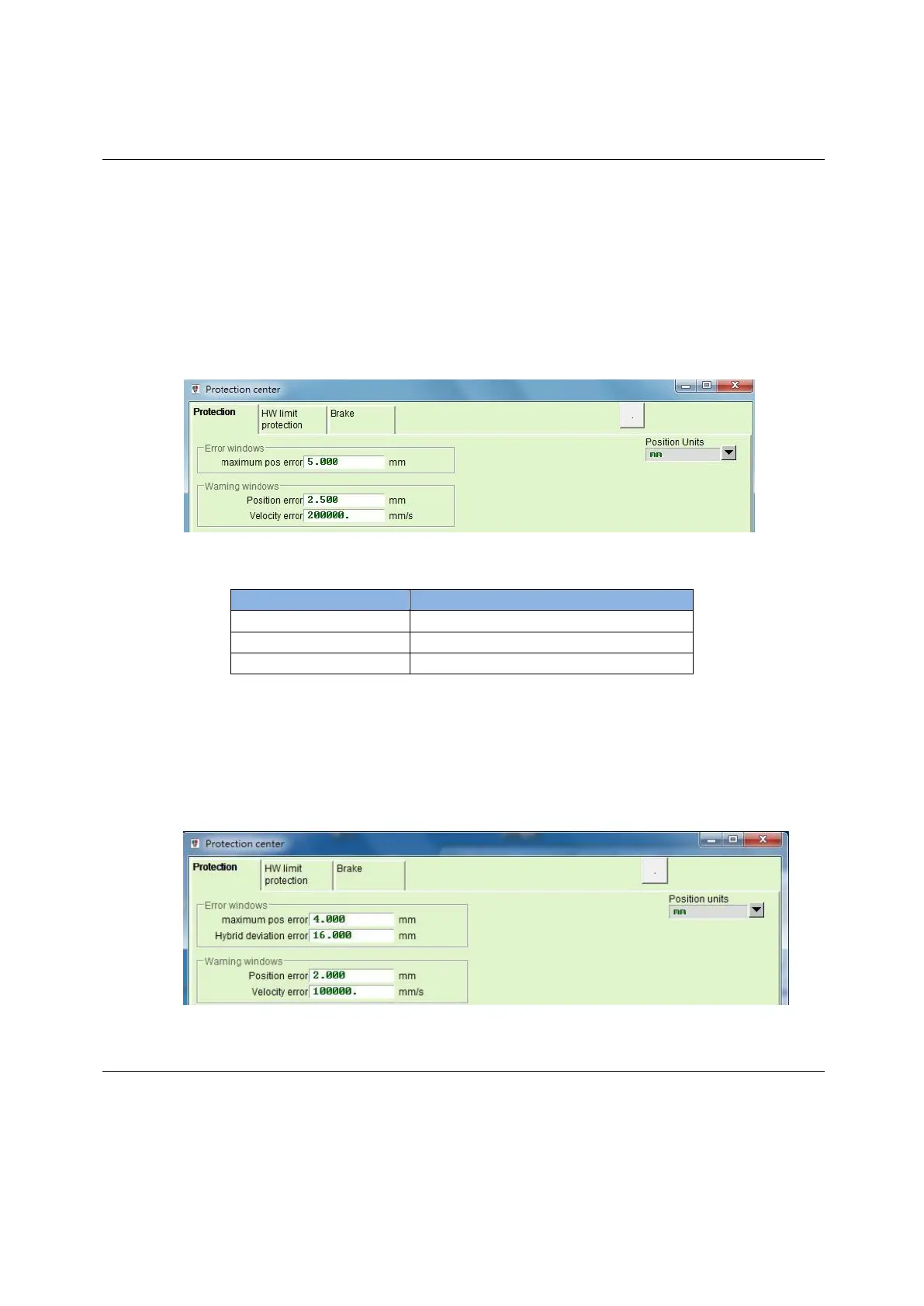

If the drive is the dual-loop model and uses the dual-loop function, the “Protection” tab in the

protection center has a “Hybrid deviation error” field to be set to prevent the mixed control

deviation from being too large, as shown in Fig. 8-5. This may cause the velocity loop or

position loop becomes unstable. When the actual error exceeds this set, the drive generates

an error message of “Hybrid deviation too big”. If the dual-loop function is not used, the

“Hybrid deviation error” field is anti-gray and cannot be set.

Fig. 8-5

8.2.2. Position error and velocity error warnings

In addition to the setting of position error limit described above, D2 drive also provides an

early warning function. When the position error or velocity error exceeds the set value in

“Warning windows”, the warning message will be displayed on the “Status” area of main

window to warn the user that an abnormality has occurred in advance.

Loading...

Loading...