D2 Drive User Guide v1.8 6. Drive Tuning

HIWIN Mikrosystem Corp. 189

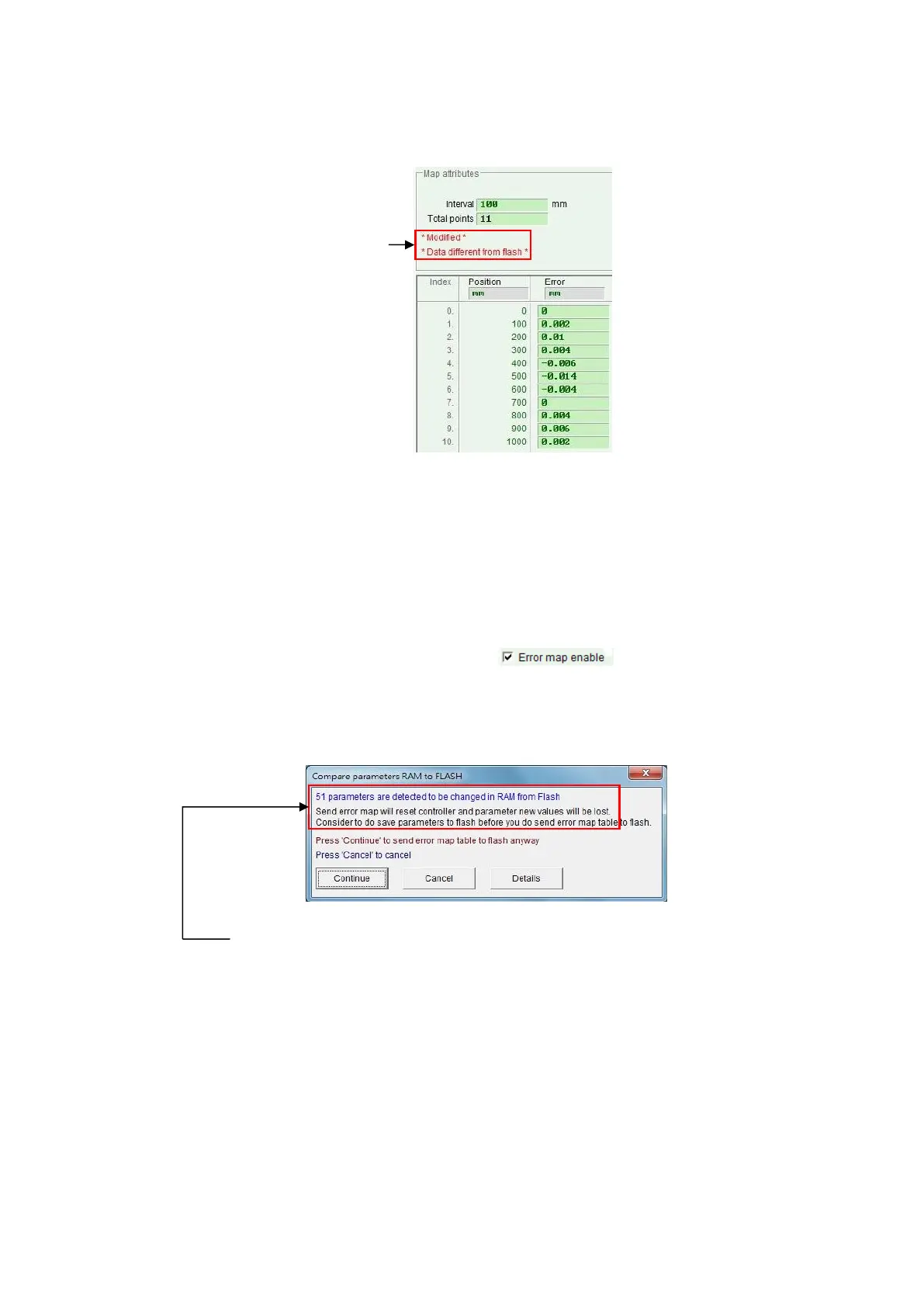

value in the “Error” field is obtained from the error measurement of laser

interferometer. For example, when the target position is 100 mm, the laser

measurement returns to 100.002 mm.

Fig. 6-61 Parameter setting of error map

Note 1. When the error compensation value is entered into the table, the entered

value is rounded to an integer multiple of encoder resolution. For example, if

the encoder resolution is 2 um and the entered compensation value is 1 um,

the program will forcibly convert it to 2 um. If the input is 0.5 um, it will be

converted to 0 um.

Note 2. Because the displayed accuracy is only to the third decimal, select the

appropriate unit for “Position” and “Error”.

Step 3. Check the option of “Error map enable” ( ).

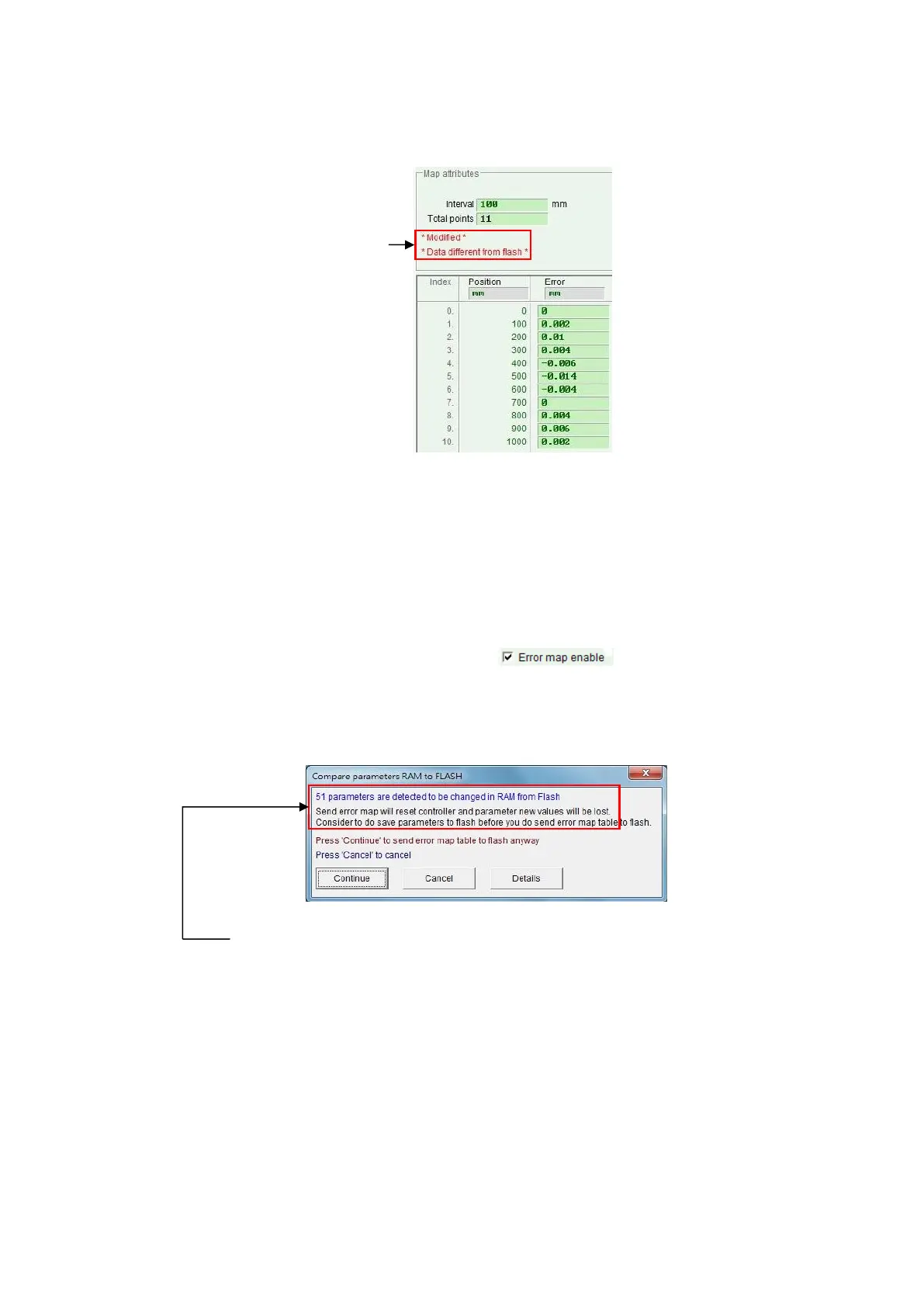

Step 4. Choose the “Send table to flash” option of “Flash” in the function menu. If there are

other parameters modified except error map parameters, and not yet saved in Flash,

the following window will be displayed. If there is no parameter needed to save

except error map parameters, go to Step 6.

Fig. 6-62

Step 5. Click the “Cancel” button and go to the HMI main window to save servo parameters

into Flash. After servo parameters are saved, redo Step 4.

Step 6. When the “confirm” window appears, click the “Confirm” button to save error map

parameters into Flash. After erro map parameters are saved, the drive will

automatically execute the “Reset” action.

reminder to

inform that the

modified

compensation

value has not

been saved to

the drive’s

Current parameters except error map parameters are different from those

in the drive’s Flash. If click the “Continue” button to save error map

parameters to Flash, servo parameters will be lost due to the forced

Loading...

Loading...