Commissioning

Chapter 2 OPERATION MANUAL

V1.3.0en/06.07.15//14.06 Liability for errors and misprints excluded. CC®

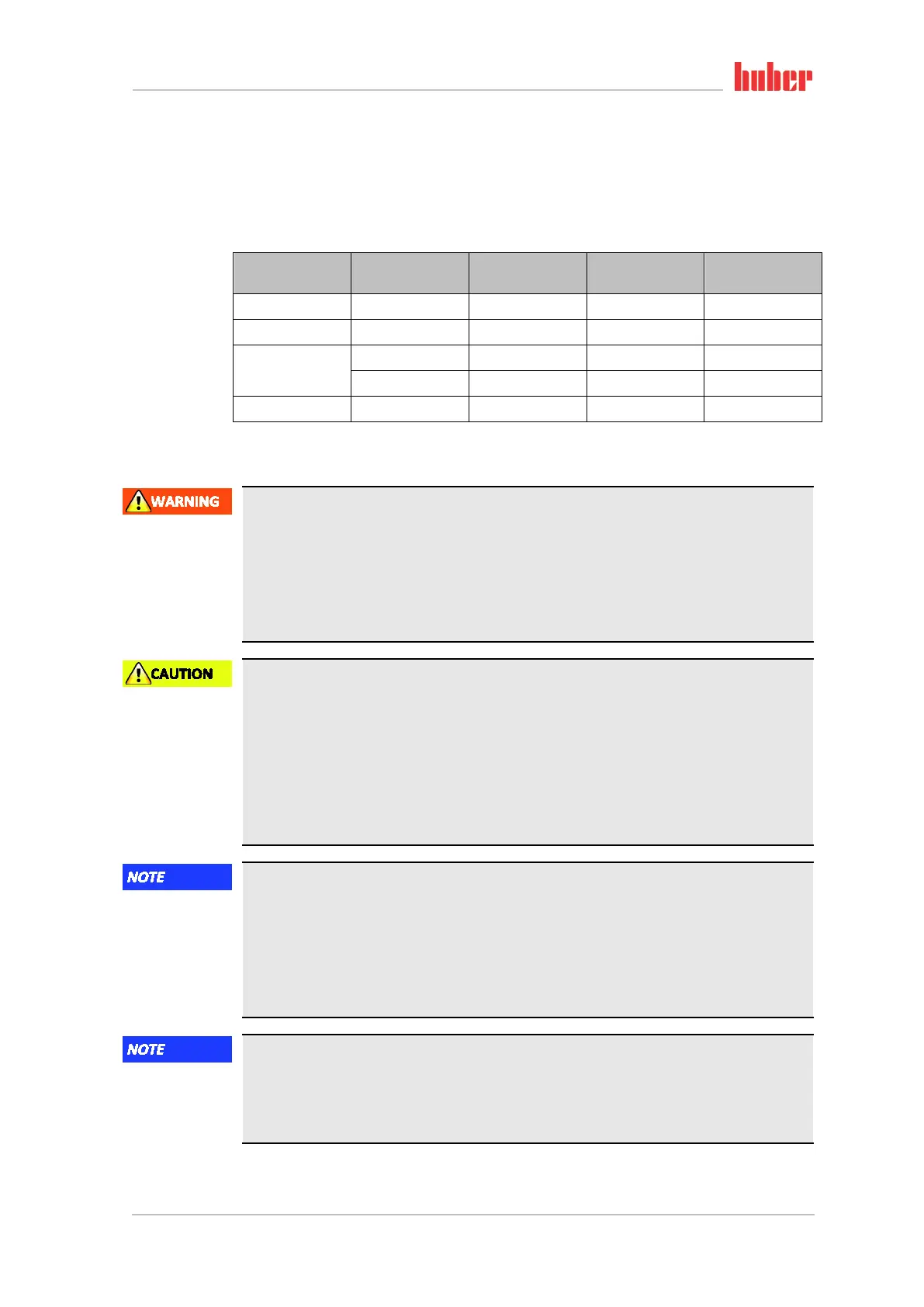

2.6 Wrench sizes and torques

Note the wrench sizes that result for the pump connection on the temperature control unit. The

following table lists the pump connections and the resulting wrench sizes, and torque values. A leak

test must always be performed, and the connections tightened if necessary. The values of the max-

imum torque (see table) must not be exceeded.

Pump connection

Sleeve nut wrench

size

Connector wrench

size

Recommended

torques in Nm

Maximum torques

in Nm

M16x1 19 AF 17 AF 20 24

M24x1.5 27 AF 27 AF 47 56

M30x1.5

36 AF 32 AF 79 93

36 AF 36 AF 79 93

M38x1.5 46 AF 46 AF 130 153

2.7 Temperature control units with water cooling

Open electrical wires below the temperature control unit at cooling water inlet temperatures

below 10 °C.

DEATH FROM ELECTRICAL SHOCK BY WATER ENTRY INTO THE ELECTRIC LINES.

A cooling water inlet temperature below 10 °C may result in condensation in the temperature

control unit and at the cooling water connections. The condensation is caused by high humidity

at the cooling water-bearing components. In this case, the condensation exists the tempera-

ture control unit at the bottom.

Electrical lines directly below the temperature control unit must be protected against liquid

Use of unsuitable/defective hoses and/or hose connections

INJURIES

Thermal fluid

Use appropriate hoses and/or hose connections.

Check periodically for leaks and the quality of the hose and hose connections and take suitable

measures (replace) as required.

Isolate and protect temperature control hoses against contact/mechanical load.

Cooling water

Reinforced hoses must be used to satisfy tougher safety requirements.

Shut off the cooling water supply to the temperature control unit even for shorter downtimes

No protection against corrosion

DAMAGE TO THE TEMPERATURE CONTROL UNIT

The addition of anti-corrosion agents is mandatory if salts (chlorides, bromide) have been

added to the water circuit.

Ensure that the materials used in the cooling water circuit are resistant with respect to the

cooling water. See the data sheet from page 83 in section »Annex« for information on the ma-

terials used.

Take suitable measures to maintain the warranty conditions.

For information about water quality, see www.huber-online.com.

Usage of un-filtered river or sea water as cooling water

DAMAGE TO THE TEMPERATURE CONTROL UNIT

Un-filtered river or sea water is not suitable for use as cooling water due to the contaminants.

Use drinking water of filtered river or sea water for cooling.

Die Partikelgröße von Schwebstoffen darf 5 µm nicht überschreiten.

For information about water quality, see www.huber-online.com.

Overview wrench sizes

and torques

Loading...

Loading...