Service/maintenance

OPERATION MANUAL Chapter 7

CC® Liability for errors and misprints excluded. V1.3.0en/06.07.15//14.06

PROCEDURE

Switch off the temperature control unit. Do this by turning the >Mains switch< [37] to the “0”

position!

Disconnect the temperature control unit from the current supply.

Release the >Fixing screw for Pilot ONE< [89] at the front of the housing.

Carefully pull the “Pilot ONE” away upwards.

Carefully insert the replacement “Pilot ONE”.

Connect the >Fixing screw for Pilot ONE< [89] to the front of the housing.

Connect the temperature control unit to the power supply.

Switch the temperature control unit on.

7.4 Maintenance

Cleaning/maintenance while the temperature control unit is operating

MORTAL DANGER FROM ELECTRIC SHOCK

Stop an ongoing temperature control process.

Disconnect the temperature control unit from the power supply by turning the >Mains switch<

[37] on the temperature control unit to “0”.

Also disconnect the temperature control unit from the current supply.

Carrying out maintenance work not described in this operation manual

DAMAGE TO THE TEMPERATURE CONTROL UNIT

For maintenance work not described in the operation manual, contact Peter Huber

Kältemaschinenbau GmbH.

Maintenance work not described in this operation manual is reserved for qualified specialists

trained by Huber.

Only perform the following maintenance work on the temperature control unit yourself.

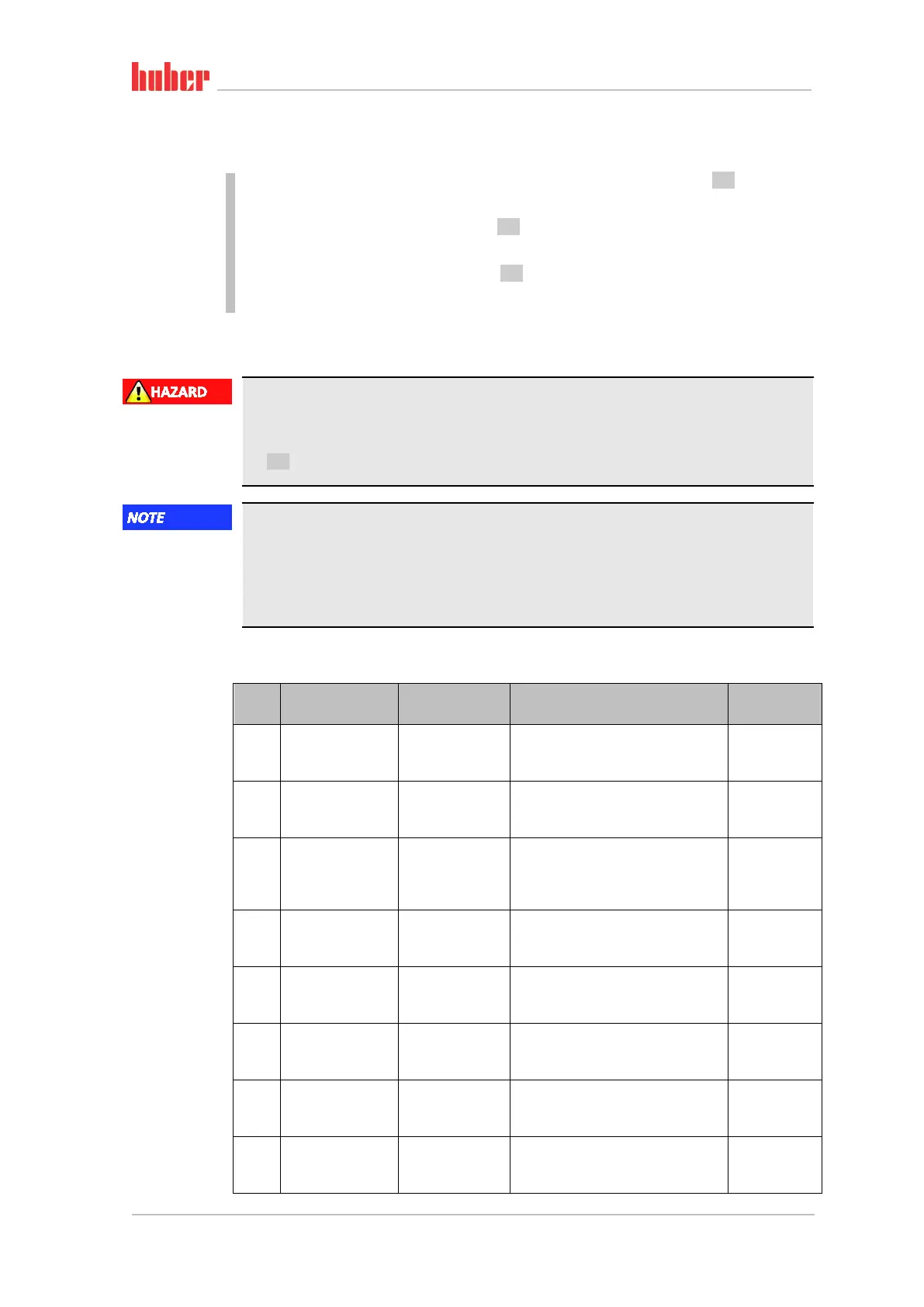

7.4.1 Function check and visual inspection

Cool-

ing*

Description

Maintenance

interval

Comment

Person re-

sponsible

L/W

Visually inspect

hoses and hose

connections

Prior to switching

on the tempera-

ture control unit

Exchange leaking hoses and hose

connections prior to switching on the

temperature control unit.

Responsible

body and/or

operators

L/W

Inspection in ac-

cordance with the

F-Gas Directive

In accordance

with the F-Gas

Directive

See page 17, section »Temperature

control devices with fluorinated

greenhouse gases/refrigerants«

Responsible

body

L/W

Inspect power

supply cable

Prior to switching

on the tempera-

ture control unit

or on relocation

Do not start-up the temperature con-

trol unit if the power cable is damaged.

Qualified

electrician

(BGV A3)

L Clean air inlet grille As required

Clean the perforated sheet of the

temperature control unit with a damp

cloth

Responsible

body

L/W

Thermal fluid

inspection

As required

Responsible

body and/or

operators

L/W

Inspect the me-

chanical seals

Monthly

See page 79, section »Inspect the

mechanical seal«

Responsible

body and/or

operators

L Check liquefier fins

As required, after

3 months at the

latest

See page 75, section »Clean liquefier

fins (air-cooled temperature control

unit)«

Responsible

body and/or

operators

W

Check suction

strainer (dirt trap)

As required, after

3 months at the

latest

See page 76, section »Clean hat-type

strainer (dirt trap) (water-cooled

temperature control unit)«

Responsible

body and/or

operators

Monitoring interval

Loading...

Loading...