5-9: Machine Maintenance Machine Maintenance: 5-8

Servicing Valves on the High Pressure Pump

Removing a Valve

1. Remove the valve cap (30 mm) and extract the valve assembly (see Figure 5-1).

2. Remove the valve assembly (retainer, spring, valve plate, valve seat) from the valve

cavity.

3. Remove the O-ring and support from the valve cavity.

4. Examine the O-ring and replace if there is any evidence of cuts, abrasion, or

distortion.

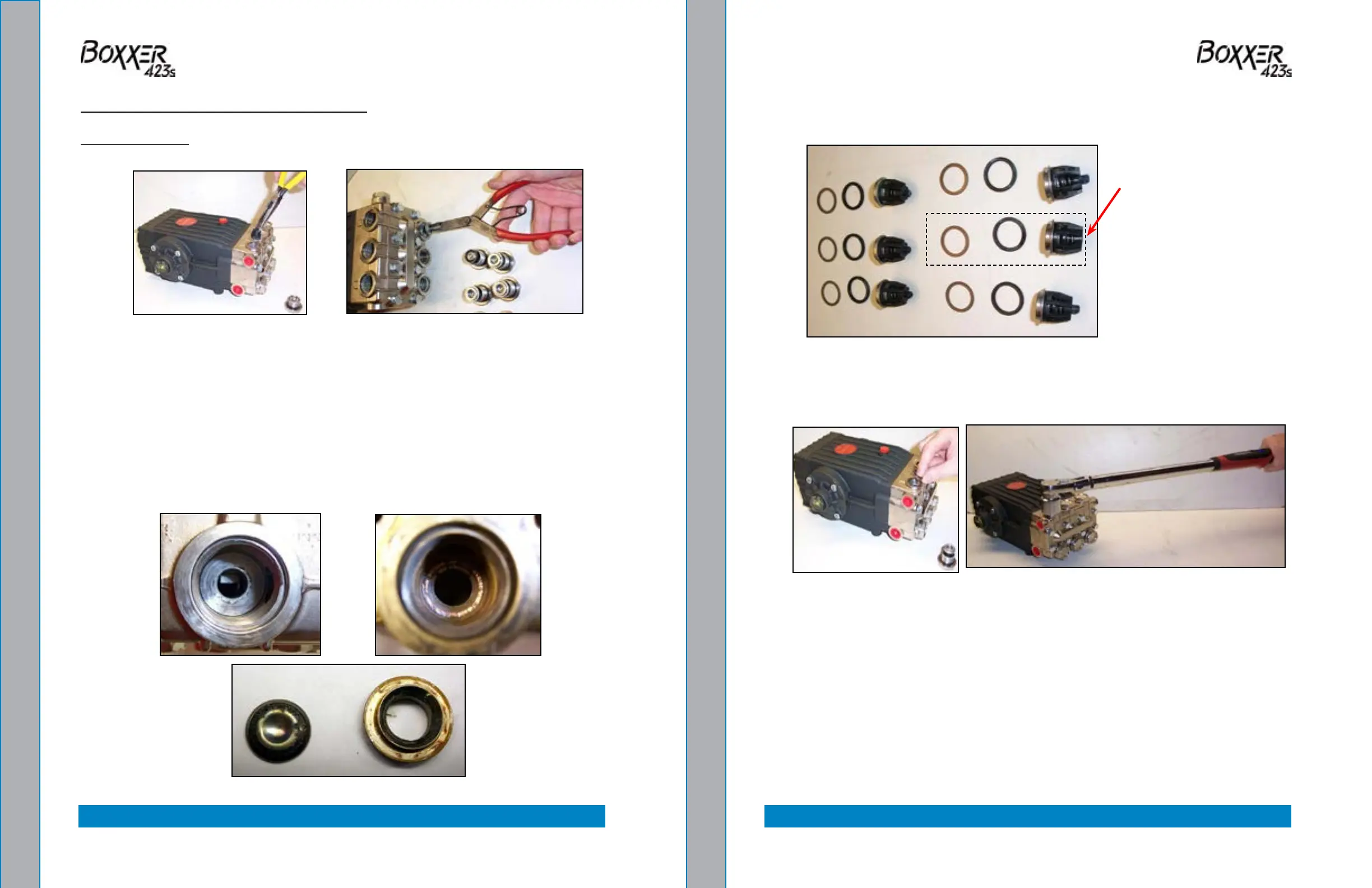

5. Inspect the manifold for wear or damage (see Figure 5-2).

6. Inspect the old valves for wear or damage. Only one valve kit (P/N 000-078-521)

is necessary to repair all the valves in the pump. (The kit includes new supports,

O-rings, valve seat, valve poppet, spring and retainer; all are pre-assembled.)

Figure 5-1. Remove Valve Cap and Valve Assembly

Figure 5-2. Inspect Manifold and Old Valves

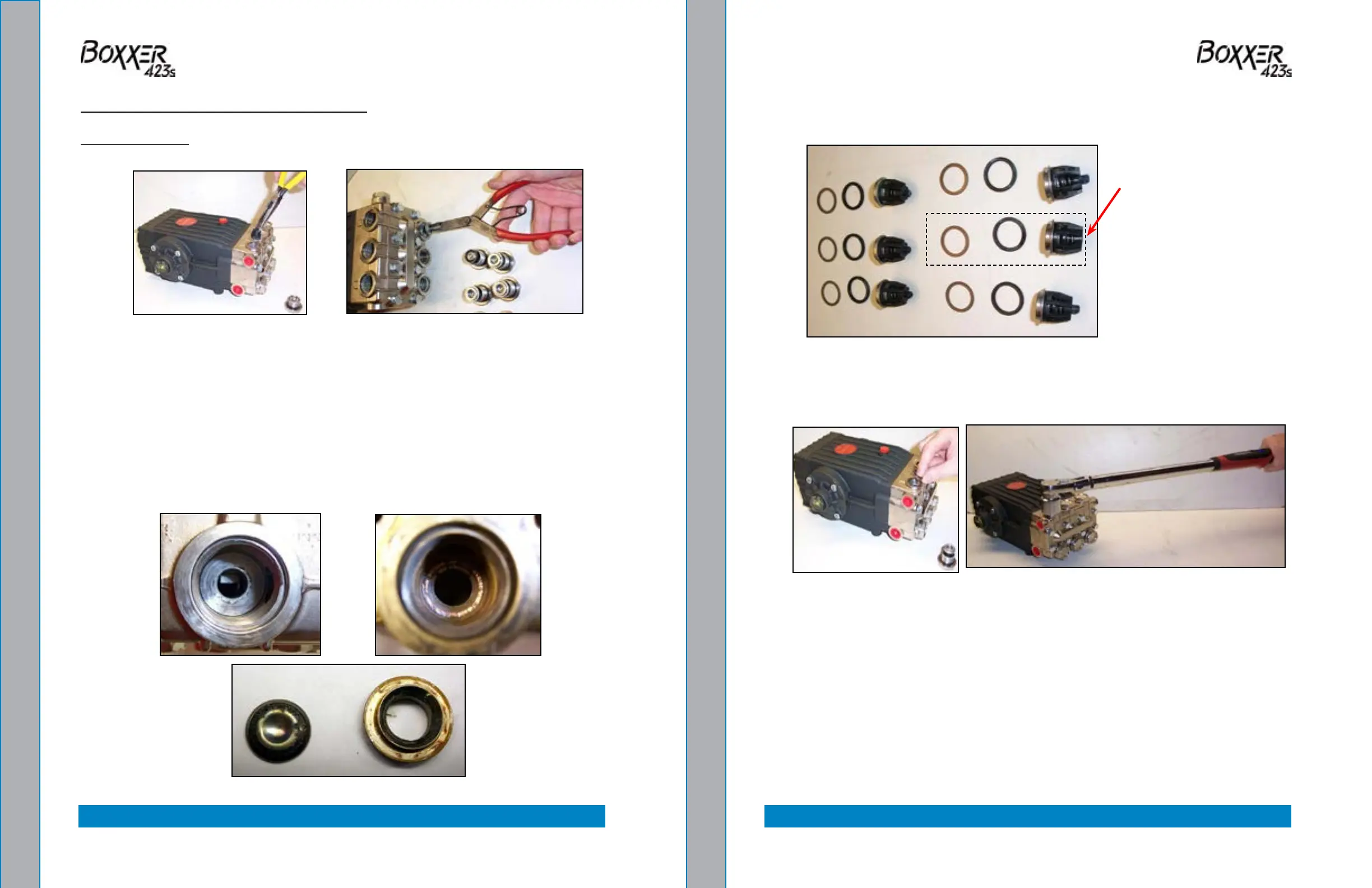

7. Replace the center inlet check valve with a modied check valve

- Figure 5-3.

8. Apply O-ring grease to O-rings and install valves (Figure 5-4).

9. Replace valve cap and torque to 95 ft lbs see Figure 5-5).

Figure 5-4. Apply Grease

and Install Valves

Figure 5-5. Replace Valve Cap

and Torque to 95 ft lbs

Figure 5-3. Replace Center Inlet Check Valve With Modied Check Valve

Modied Check Valve

Loading...

Loading...