5-11: Machine Maintenance Machine Maintenance: 5-10

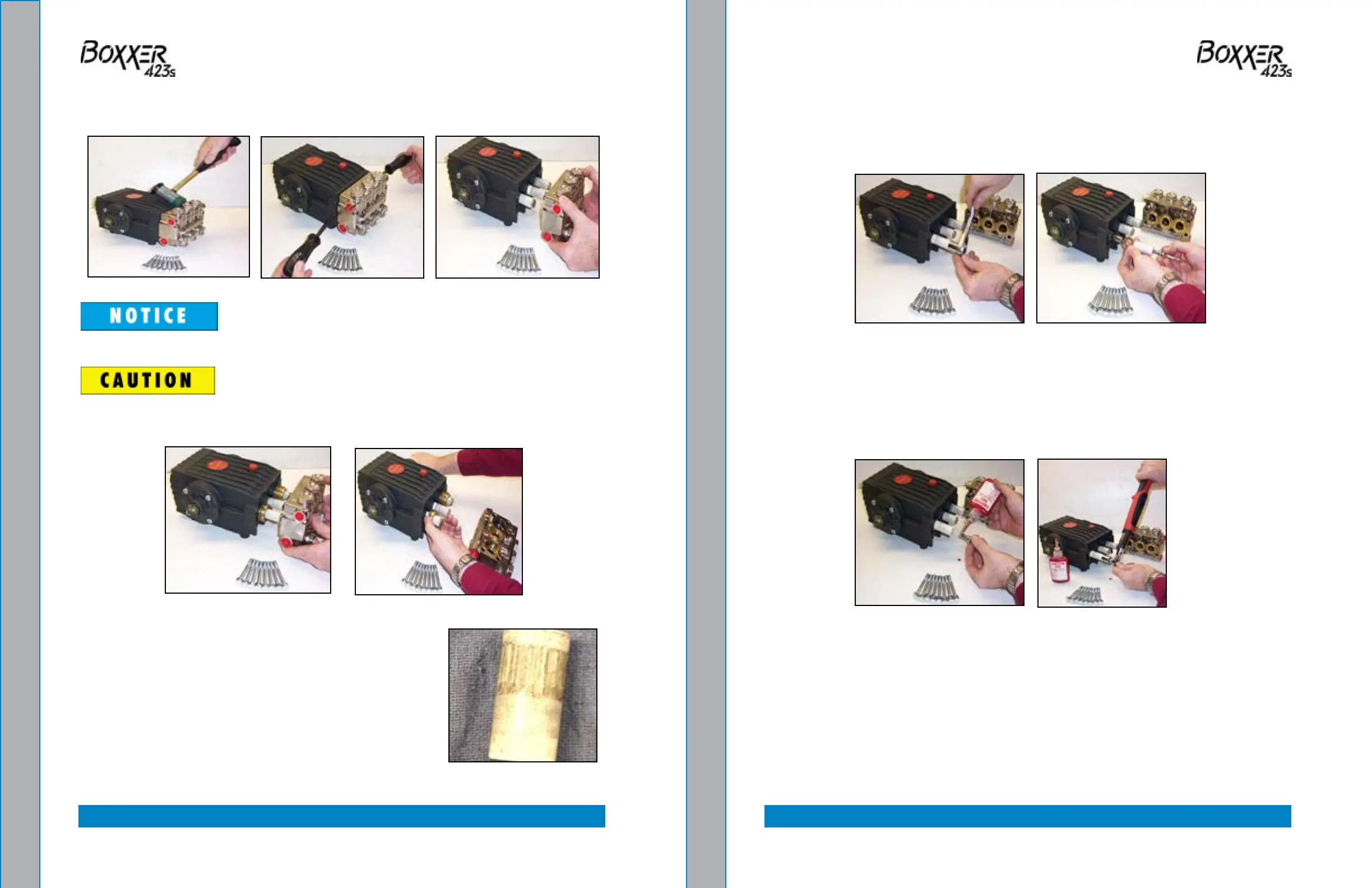

10. Remove the fasteners retaining the manifold

11. Separate manifold from crankcase (see Figure 5-6).

It may be necessary to rotate crankshaft or tap manifold with rawhide or plastic

mallet to loosen.

When sliding manifold from crankcase, use caution not to damage ceramic

plungers.

12. The seal assemblies may come off with the manifold (see Figure 5-7)

13. Examine the ceramic plungers. The surface should be

smooth and free from scoring, pitting or cracks (see

Figure 5-8); if not, replace.

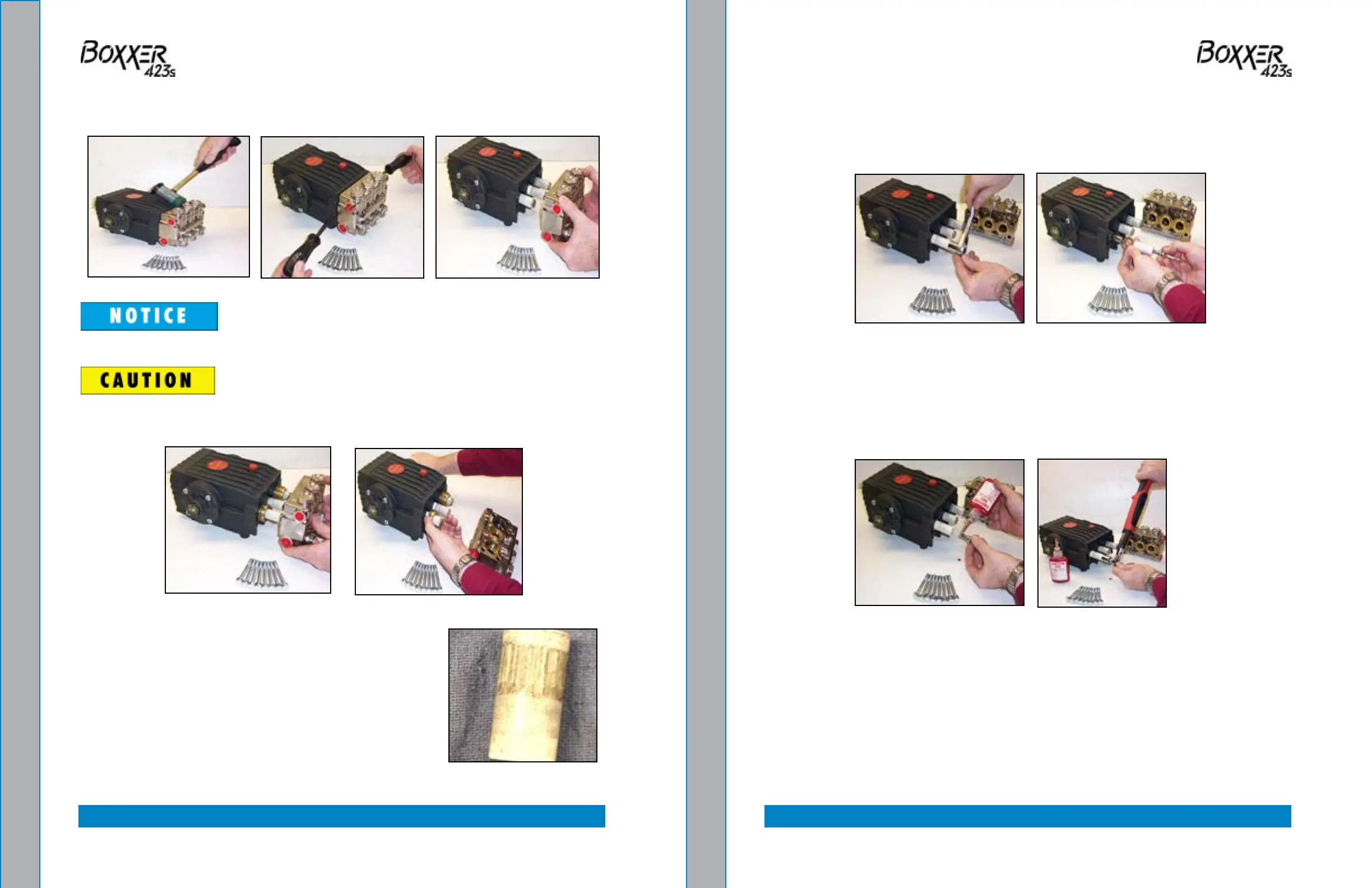

14. Loosen the stainless steel plunger bolt.

Figure 5-8. Examine

Ceramic Plungers

Figure 5-6. Separate Manifold from Crankcase

Figure 5-7. Seal Assemblies May Come Off with Manifold

15. Remove the stainless steel plunger bolt and ceramic plunger from the plunger guide

(see Figure 5-9).

16. If the slinger washer is removed, be certain it is re-installed or replaced.

17. Separate plunger bolt from ceramic plunger (see Figure 5-9).

18. Install new Teon

® back-up ring and O-ring on the plunger bolt. Apply a lm of O-ring

grease on the outside of the O-ring (see Figure 5-10).

19. Apply removable anaerobic thread sealant (Loctite

®

542) to the threads of the plunger

bolt, carefully pressing the plunger bolt into ceramic plunger (see Figure 5-10).

20. Slide new ceramic plunger over the plunger guide (see Figure 5-10).

21. Torque plunger to 14.5 ft lbs

Figure 5-9. Remove Stainless Steel Plunger Bolt and Ceramic Plunger

Figure 5-10. Install O-ring, Apply Sealant and Slide Plunger over Plunger Guide

Loading...

Loading...