8-9: Systems Troubleshooting Systems Troubleshooting: 8-8

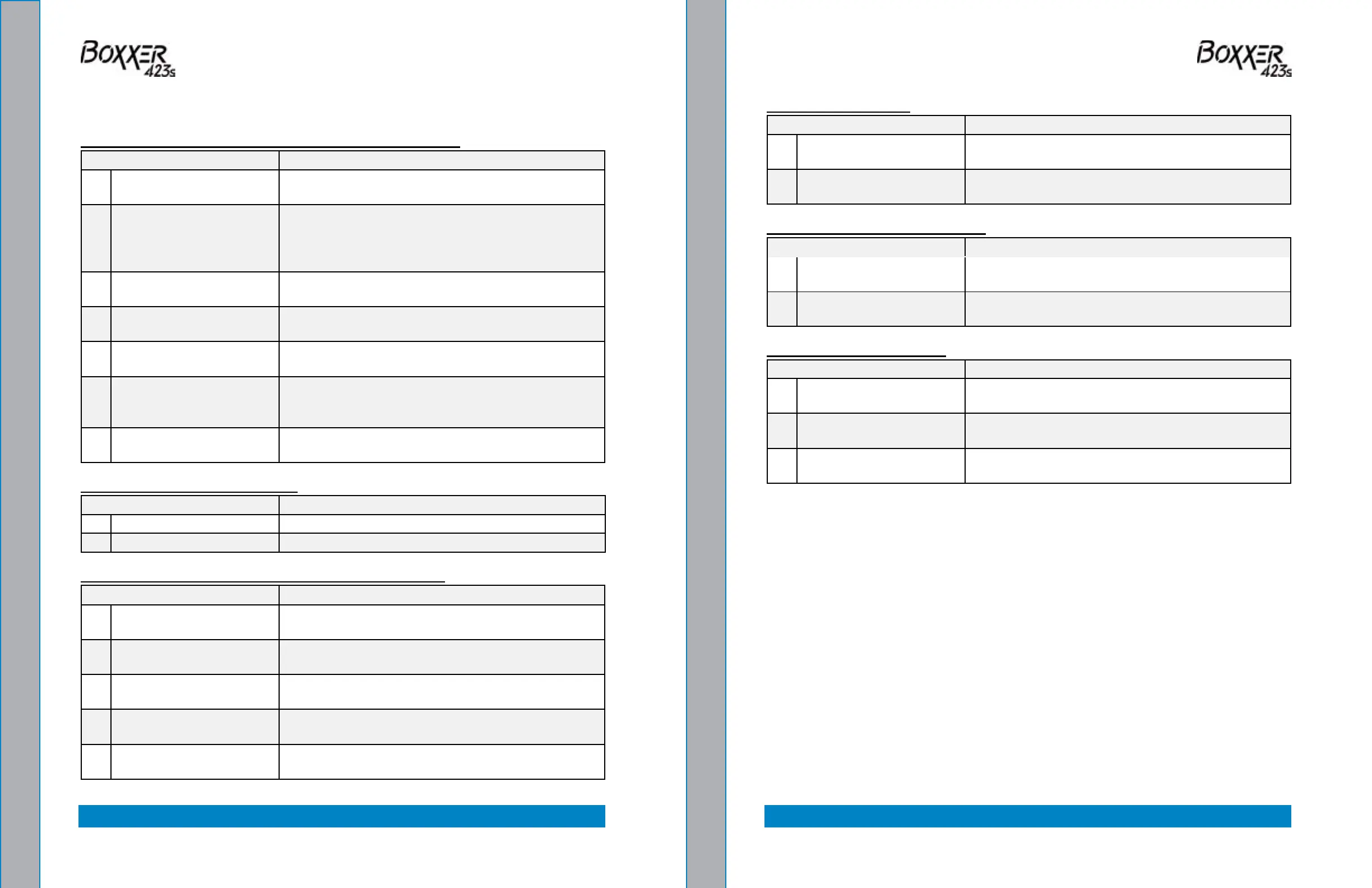

4.0 Pressure pulsation

Possible Cause Solution

4.1 Air leak between the water

box and pump.

Check all the hoses and ttings for cuts, breaks,

cracks, etc. Repair as necessary.

4.2 The check valve(s) in the

pump are faulty.

Remove each valve and inspect for correct

operation. See the Machine Maintenance Section.

5.0 Water box empty or lls slowly

Possible Cause Solution

5.1 Restriction in the water

supply system.

Inspect the supply system from the source through

the incoming quick connect.

5.2 The oat valve in the

water box is faulty.

Disassemble and inspect the valve. Repair or

replace as necessary.

6.0 The water box overows

Possible Cause Solution

6.1 The oat valve in the

water box is faulty.

Disassemble and inspect the valve. Repair or

replace as necessary.

6.2 The oat has absorbed

water and lost buoyancy.

Detach the oat and check to see if it will oat to the

surface. Replace as necessary.

6.3 The oat has come out of

adjustment.

Adjust the oat as necessary.

HIGH PRESSURE SYSTEM

1.0 The pump will not come up to normal cleaning pressure

Possible Cause Solution

1.1 The pressure adjusting

valve is faulty.

Inspect the valve. Repair or replace if necessary.

1.2 Worn seals or valves in

the pump.

Test the pump output volume directly from the pump

at normal running rpm. If the volume is below the

manufacturer’s specications, replace the seals and

inspect for defective valves.

1.3 The pump rpm is too low. Check for a loose pump belt. Adjust or replace as

necessary.

Check the engine rpm and adjust as necessary to

3,200 rpm under no vacuum load.

1.4 The primary orice is

missing or loose.

Remove and inspect. Tighten or replace as

necessary.

1.5 The primary and

secondary orices have

been installed incorrectly.

Inspect and reverse if necessary. Refer to the

Machine Assemblies & Parts List Section.

1.6 The primary orice is

worn.

Measure the orice size and replace as necessary.

Correct size is 0.021”.

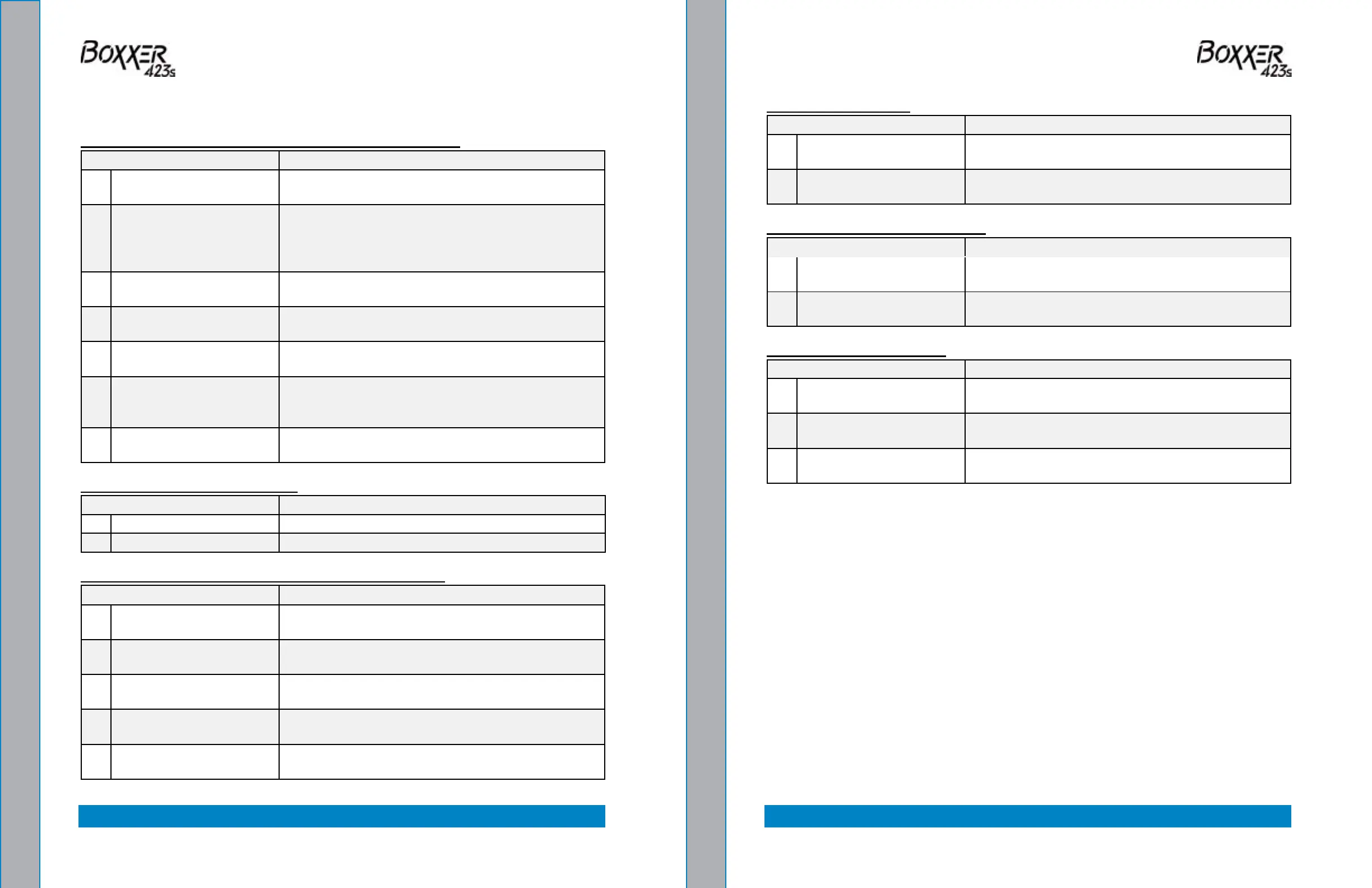

2.0 No pressure reading on gauge

Possible Cause Solution

2.1 The pump belt is broken. Inspect and replace if necessary.

2.2 The gauge is faulty. Replace the gauge.

3.0 The psi gauge reads normal; low pressure from wand

Possible Cause Solution

3.1 Restriction in the cleaning

tool.

Inspect the tool jet(s) and clean or replace as

necessary.

Inspect any lters in the cleaning tool and clean or

replace as necessary.

3.2 Faulty quick connect in the

system.

Inspect each quick connect and replace as

necessary.

3.3 Restriction in one of the

solution hoses.

Remove the quick connects and inspect hoses.

Clean or replace as necessary.

3.4 Hard water deposits

restricting the system.

Descale the truckmount.

Loading...

Loading...