8-11: Systems Troubleshooting Systems Troubleshooting: 8-10

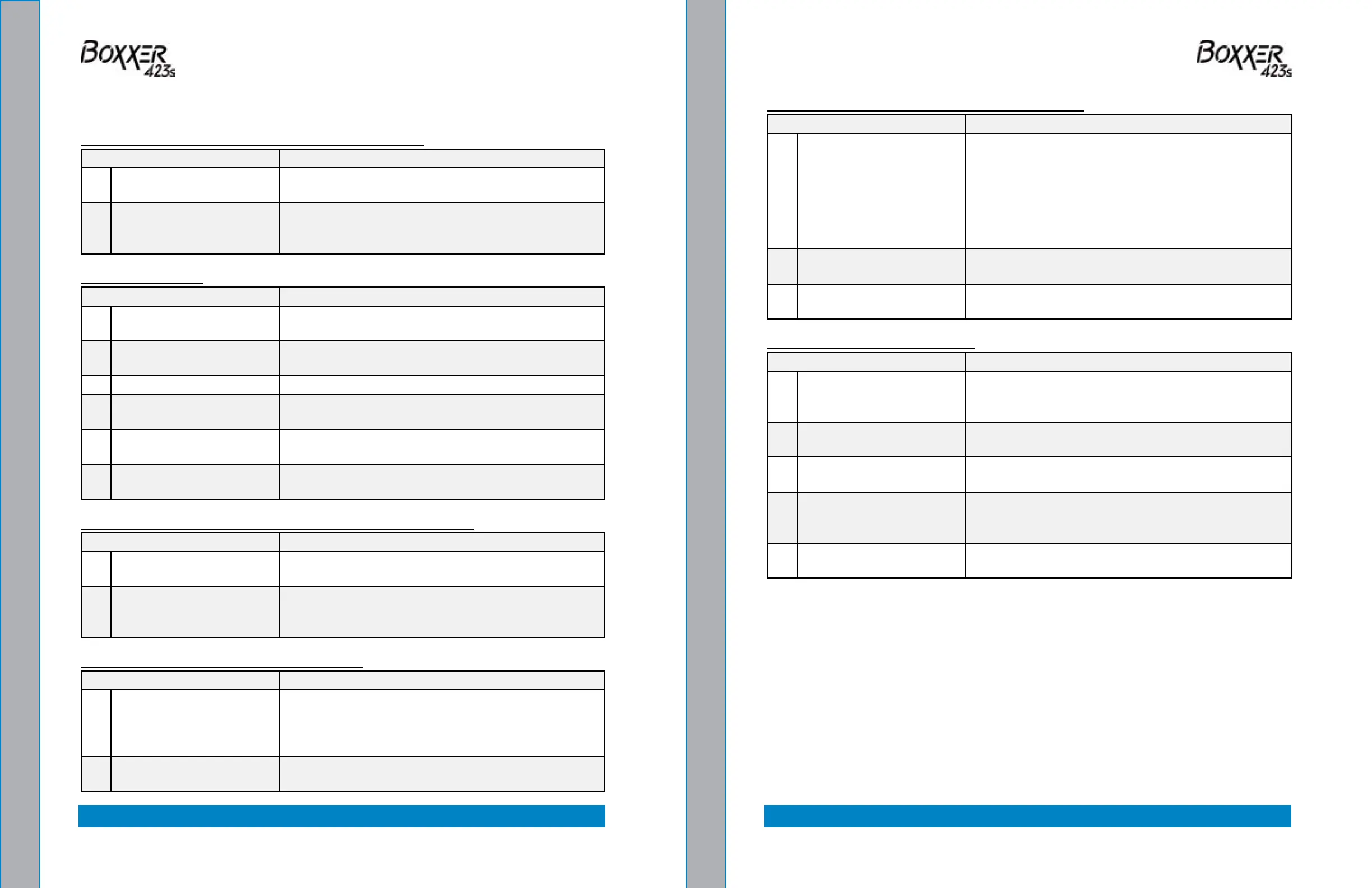

VACUUM SYSTEM

1.0 A weak vacuum at wand. The gauge reads normal.

Possible Cause Solution

1.1 Blockage in the hoses or

wand tube

Disconnect the hoses and check for an obstruction.

1.2 Excessive length of

hose connected to the

truckmount

Do not attach excessive lengths of hose.

2.0 A weak vacuum

Possible Cause Solution

2.1 Air leak somewhere in the

vacuum system.

Check the vacuum relief valve for proper adjustment.

Carefully check all the vacuum hoses for a cut or

break.

Check the recovery tank lid gasket.

Make sure the recovery tank drain valve is fully

closed.

2.2 The vacuum blower is

turning too slowly.

Check the rpm of the engine. Adjust as necessary to

3,200 rpm under no vacuum load.

2.3 The vacuum gauge is

defective.

Test the gauge and replace if necessary.

3.0 The vacuum gauge reads too high with no hoses attached

Possible Cause Solution

3.1 The lter in recovery tank

is clogged.

Remove and clean or replace as necessary.

3.2 The hose from recovery

tank to the vacuum blower

is collapsed internally.

Inspect and replace as necessary.

4.0 Excessive noise produced by the blower

Possible Cause Solution

4.1 The blower is low on oil. Inspect the oil levels and replenish as necessary.

Note: Running the blower with low oil levels can cause

severe damage. If this situation occurs the blower

should be inspected by a qualied service technician.

4.2 The vacuum blower has

internal damage.

Refer to a qualied service technician.

5.0 The vacuum blower is locked and will not turn

Possible Cause Solution

5.1 Truckmount has been

inactive for a period of

time and the blower was

not properly lubricated

prior to nal shutdown.

Rust has possibly built up

on the internal surfaces.

Spray penetrating oil into the blower and let sit for

at least 1 hour. Then very carefully use pipe wrench

on the outer diameter of the pulley on the coupler

to attempt to free lobes of the blower. Do not use a

wrench directly on the blower shaft.

If unable to free up the blower in this manner, refer to

a qualied service technician.

5.2 There is internal damage

to the blower.

Refer to a qualied service technician.

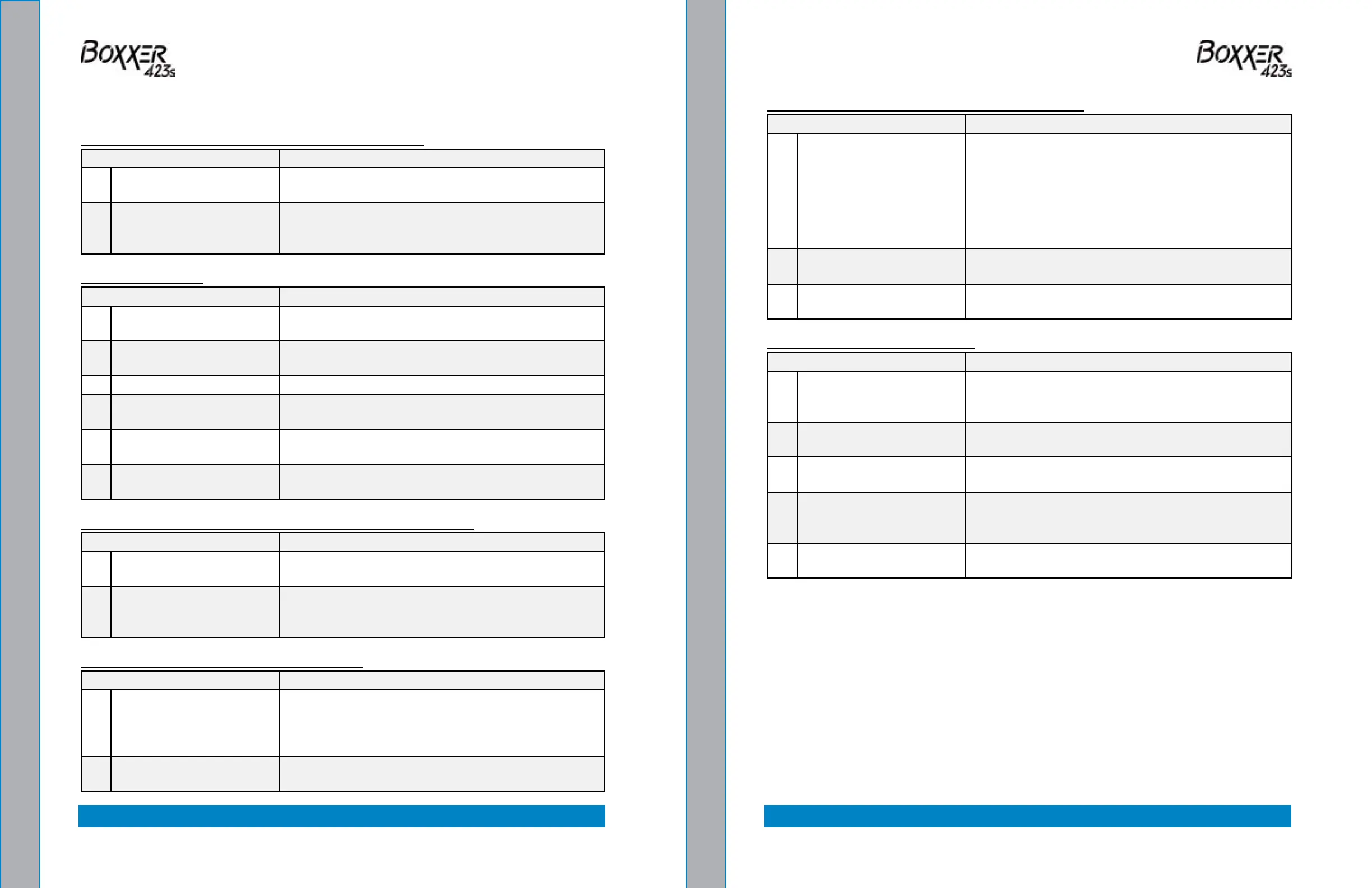

6.0 Water in truckmount exhaust

Possible Cause Solution

6.1 The recovery tank has

been lled with foam or

overlled with water.

Inspect the recovery tank. If full, drain the tank.

Inspect the high level shutoff switch for proper

operation. Clean or replace the switch as necessary.

If foam is in recovery tank, use defoamer on the

carpet being cleaned.

6.2 Condensation in system. This will be more common in cool weather and humid

climates. If this is the cause, it should dissipate after

a few minutes of running.

6.3 The heat exchanger is

leaking water.

Inspect and repair or replace as necessary.

Loading...

Loading...