2-3: Operating Instructions

7. Block o the vacuum inlet to the waste tank and allow TM to warm up for 2-3 minutes.

8. Attach and route drain hose for Auto Pump Out if equipped/necessary. Turn on APO.

The PUMP OUT system will not engage until the water level rises inside the recovery

tank.

9. Un-cap vacuum and attach vacuum hose to unit and cleaning tool.

10. Begin cleaning.

The machine will automatically shut down when it reaches its full capacity due to

the oat switch located inside the recovery tank. When this occurs, turn the Solution

Control switch to “OFF” and empty the recovery tank. Then, turn the unit back on and

continue to clean.

LTR

REVISION DESCRIPTION

CODE

DATE

BY

CHKD

APPVD

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

MACHINE

FINISH

125

SCALE: 1:4

SHEET 1 OF 1

PROPRIETARY INFORMATION

11015 47th Avenue West,

Mukilteo, Washington 98275

D

SIZE

BREAK ALL SHARP EDGES 0.005-.015

UNLESS OTHERWISE NOTED

DIMENSIONS ARE IN INCHES

PART NUMBER

WEIGHT:

APPLICATION

NEXT ASSY

USED ON

610-018-749

REV

ASSEMBLY, DASH - CTS 403 FLEX

PRJ000245

CTS 403 FLEX

610-050-749

- - - - - -

- - -- - -

- - - - - -

- - - - - -

M.B.B.

M.B.B.

L.O.L.

DRAWN

CHECKED

APPVD

12/18/2019

12/19/2019

12/19/2019

TOLERANCES

.X=

.1

.XX=

.03

.XXX=

.010

ANGULAR =

2°

CODE:

21.09

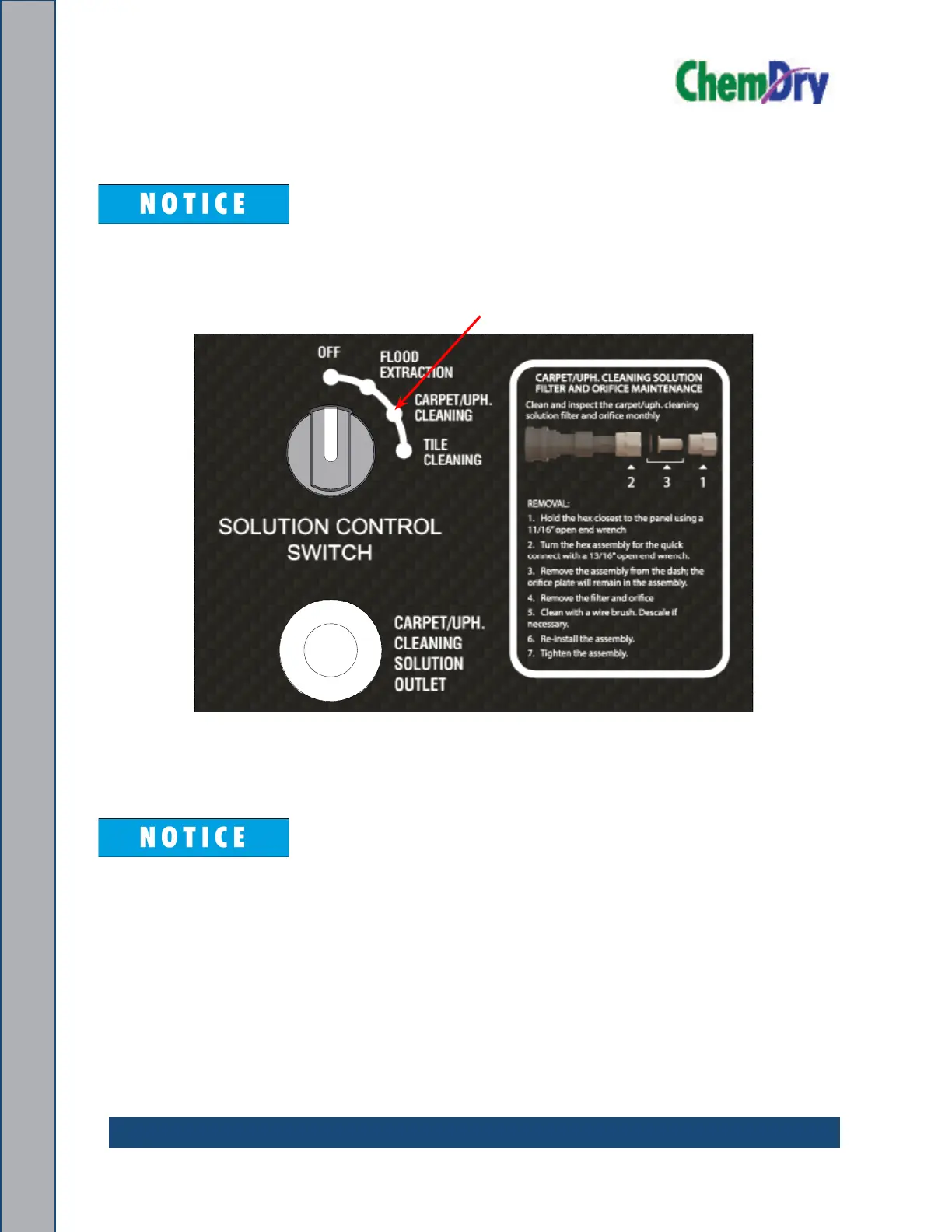

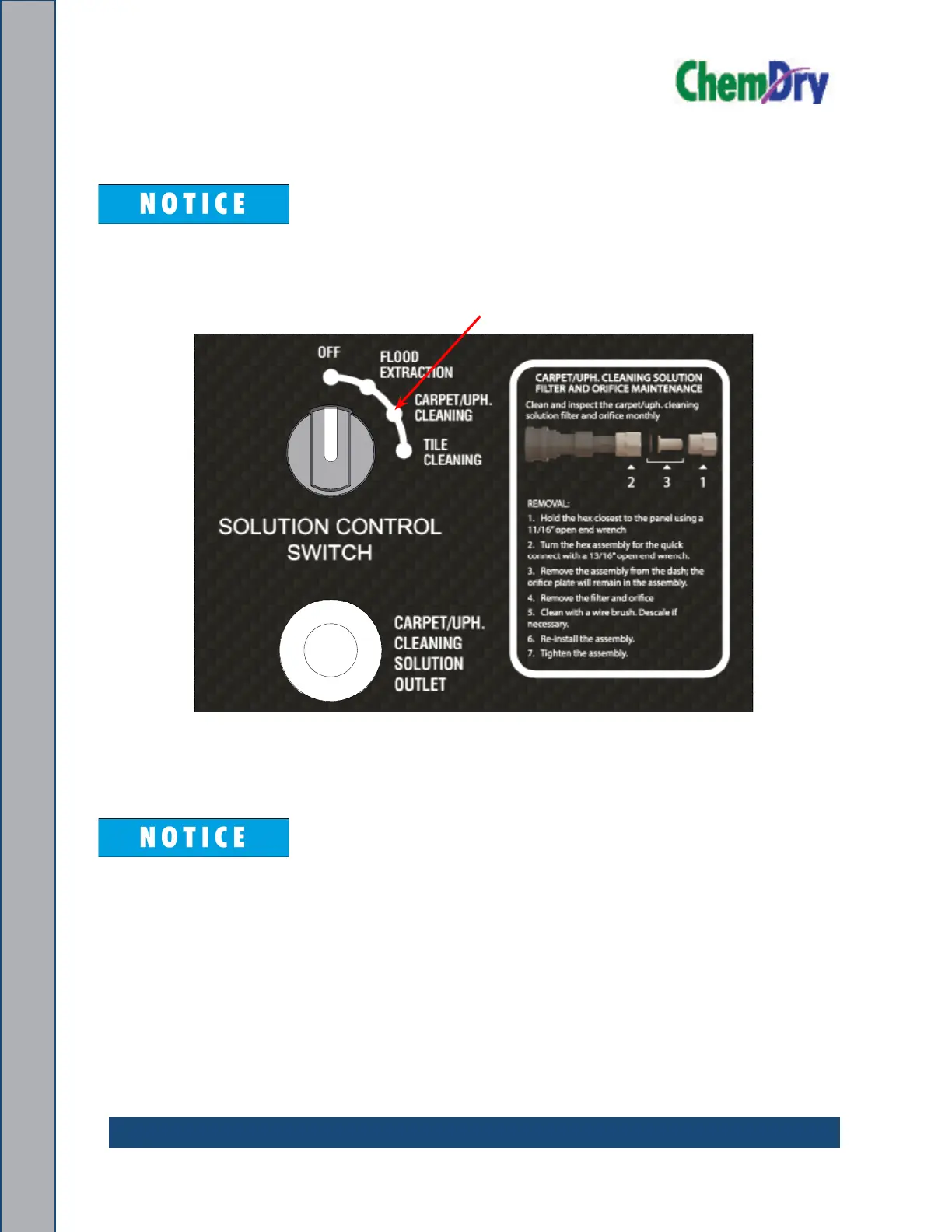

CARPET/UPH.

Selection

Figure 2-2. Select “CARPET/UPH.” on Solution Control Switch

Loading...

Loading...