4-5: Machine Maintenance

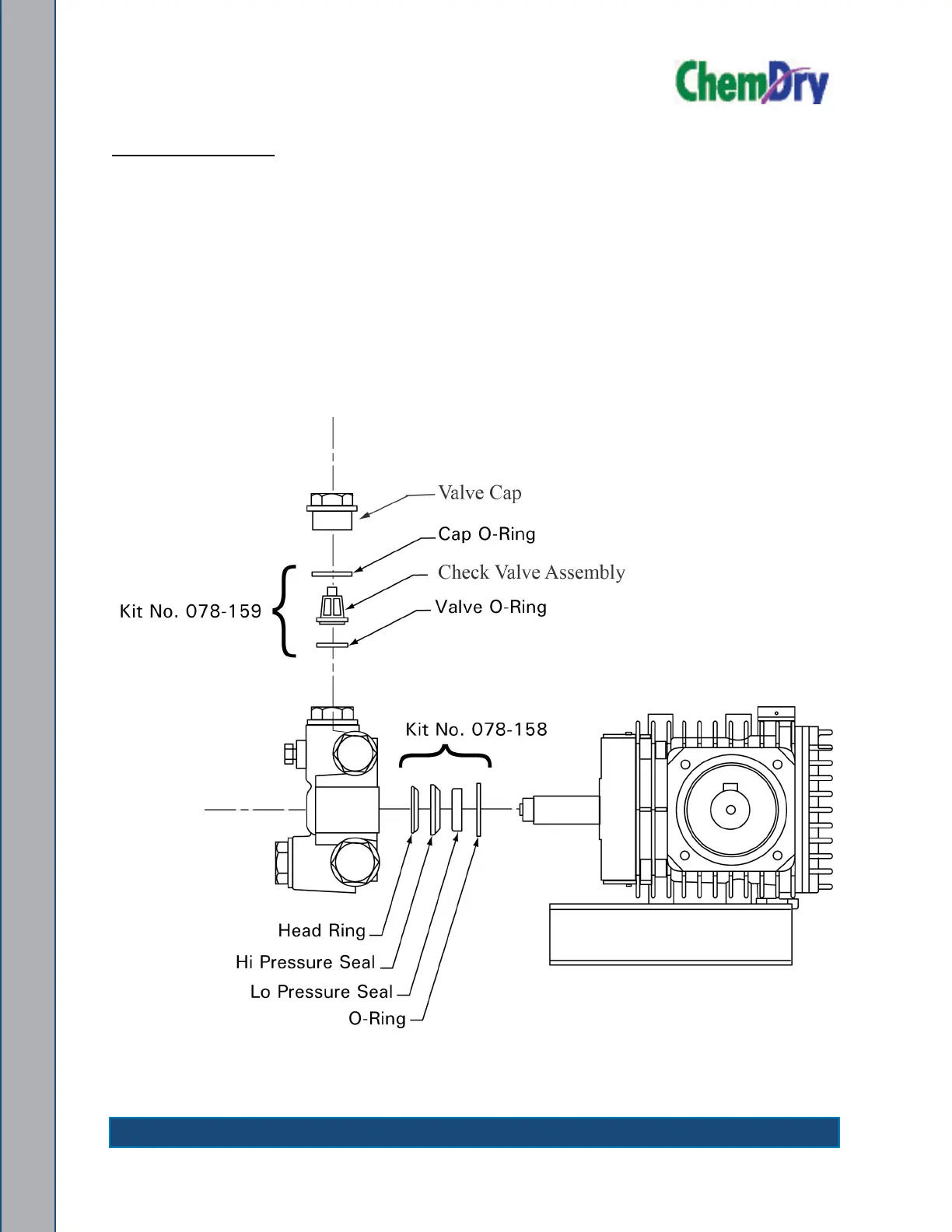

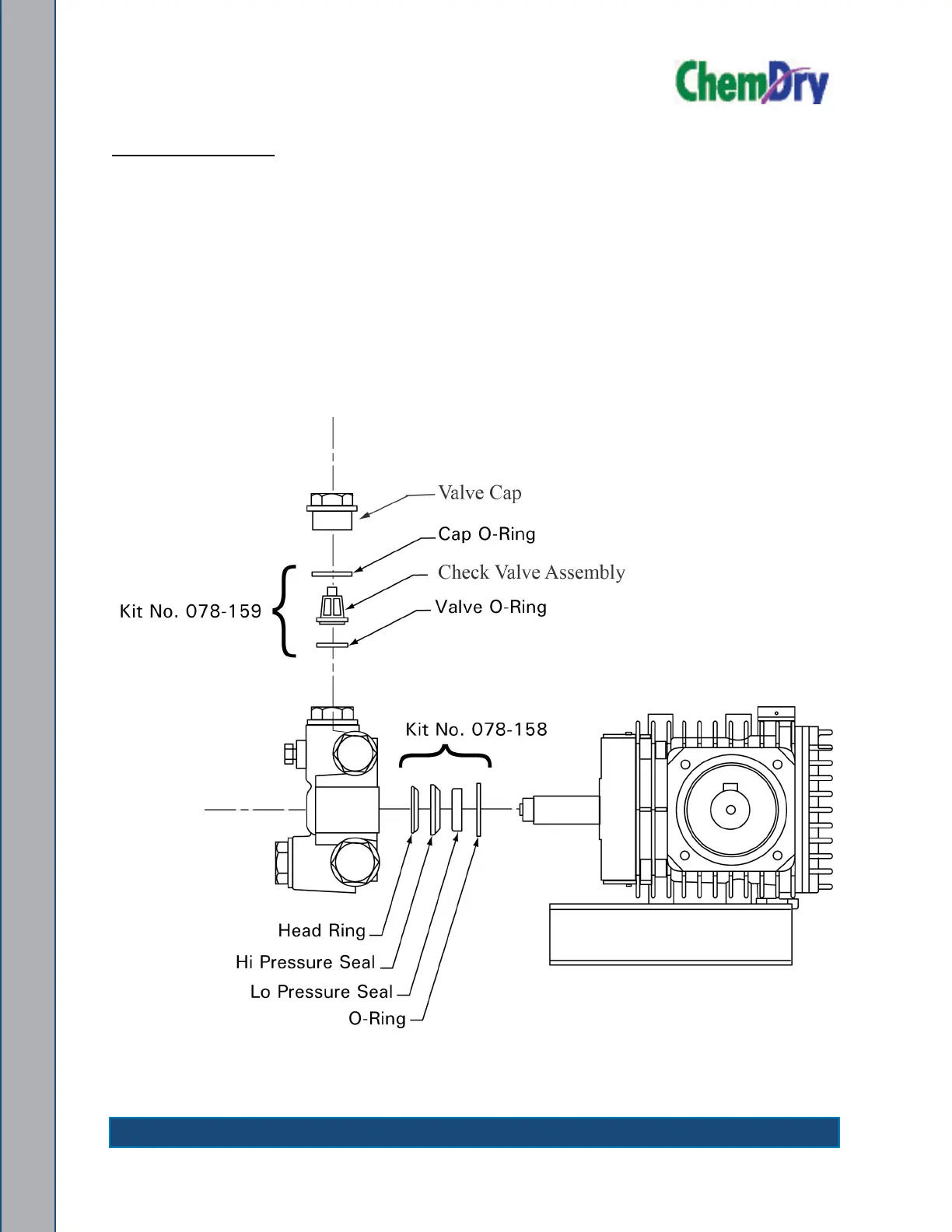

Valve Maintenance (See Figure 4-1)

1. Using a 22-mm wrench or socket, remove all six valve caps on the manifold of the

pump.

2. Examine each valve cap O-ring for cuts or distortions and replace if worn.

3. Using needle nose pliers, remove the suction and delivery check valves. The valve

assembly usually stays together when removing. If the valve comes apart, use the

needle nose pliers or reverse pliers to remove the remaining parts.

4. Inspect each suction and delivery check valve assembly for wear and pitting, and

replace if necessary. The valve assembly consists of the plastic cage, spring, valve

seat, poppet and O-ring. One valve kit is needed for complete valve change of one

pump.

Figure 4-1. Servicing the Valves

Loading...

Loading...