47

X-Series Waterblast Unit

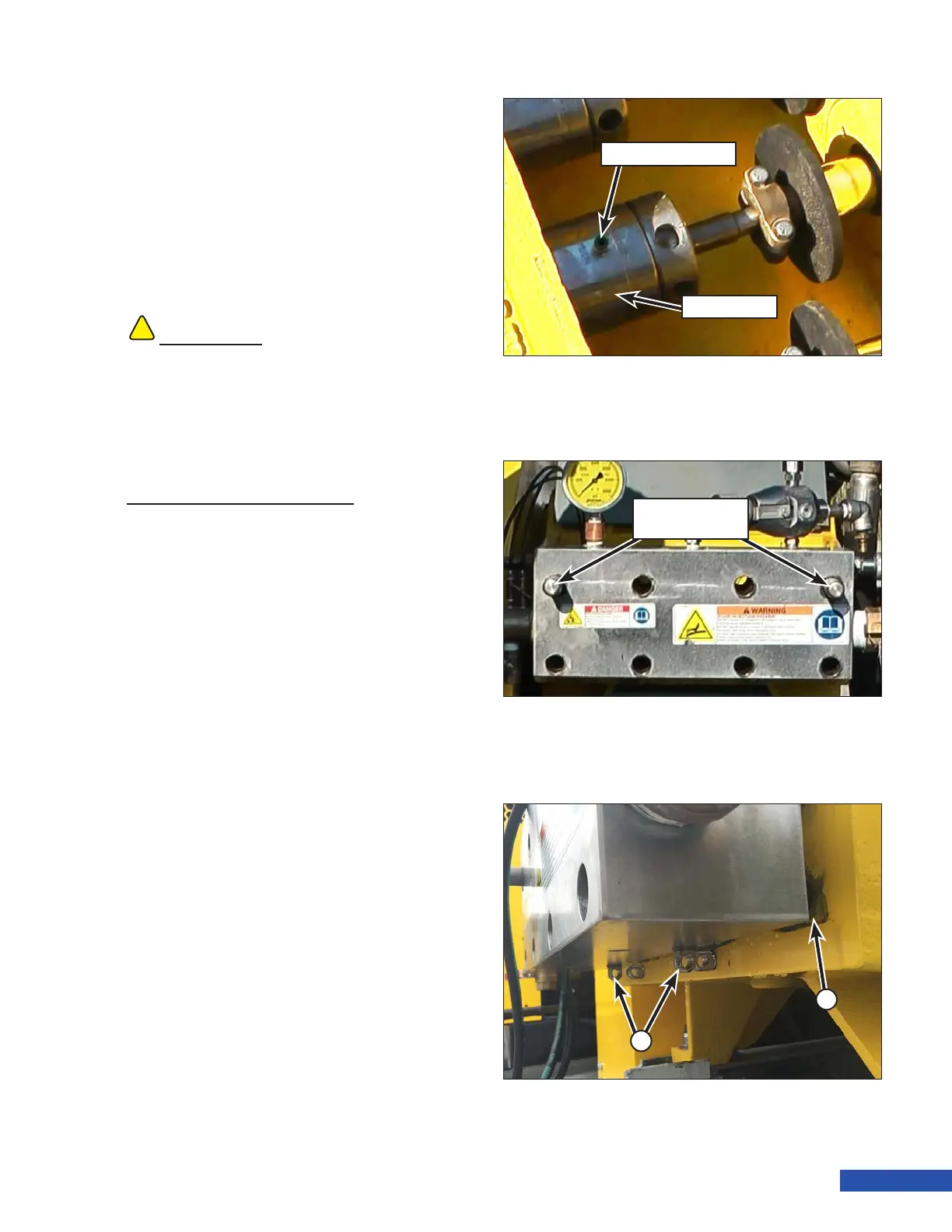

18. Apply Teon tape to the threads of the

lubrication line ttings (Figure 70). Install

the ttings onto the stufng boxes.

19. Apply a light coating of petroleum jelly

or Anti-Seize to the mounting face of the

power end. This will greatly reduce the

buildup of corrosion.

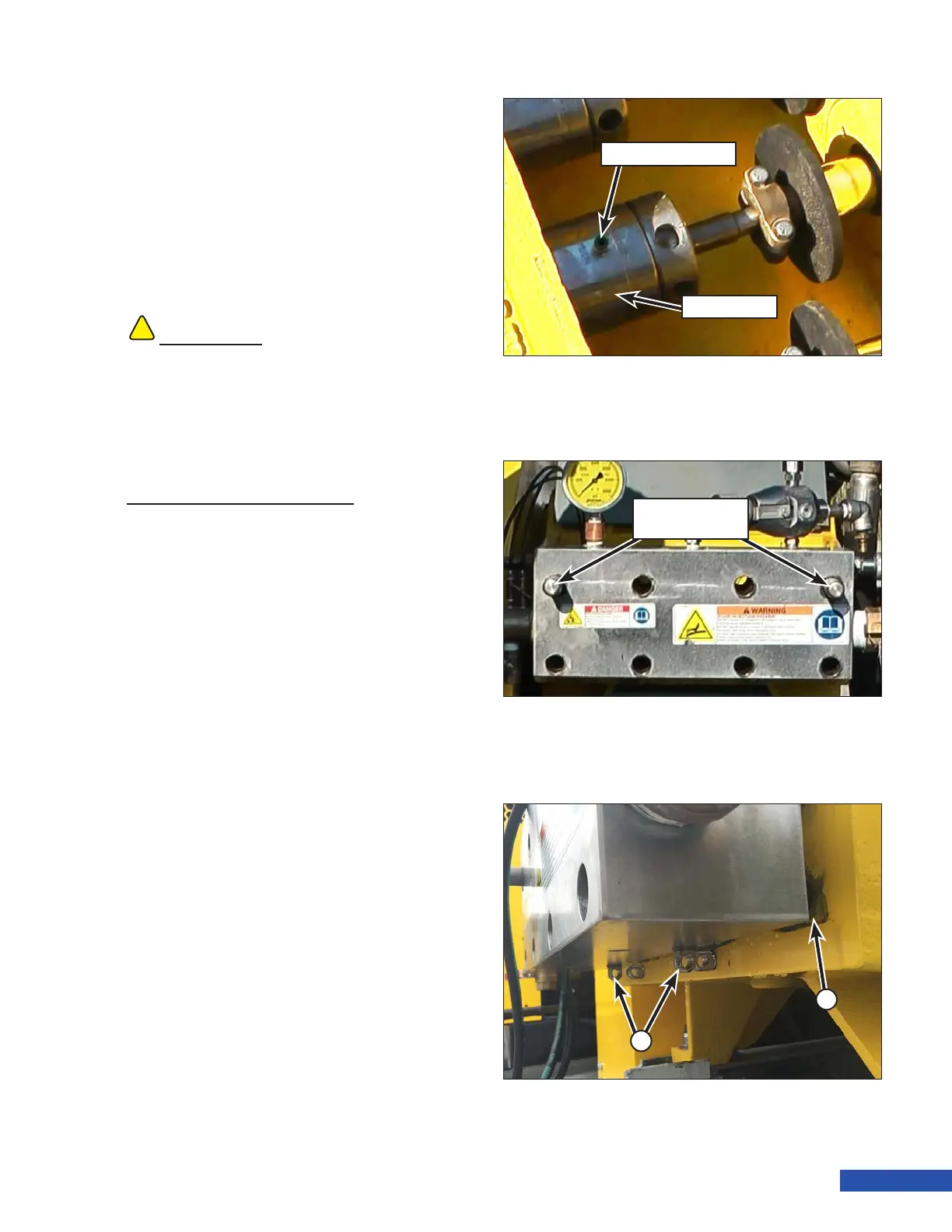

20. Lift the new manifold onto the manifold

mounting studs (Figure 71).

21. Install and adjust the trunnion rod as fol-

lows:

Manifold Trunnion Adjustment

The trunnions in the manifold must be

adjusted such that the hinge rod supports

the manifold to allow the capscrews to be

screwed in or out by hand. The manifold

holes need to be centered over the tapped

holes in the powerframe (or adapter plate).

This conguration will put the hinge rod in

a substantial bind and it will be bent down

slightly at the ends since it will be supporting

the weight of the manifold block. This

centered position of the manifold will also

ensure proper operation of the valves and

seals at all pressures.

a. Slide the manifold away from the

powerframe (or adapter plate) a few

inches (Figure 72, A). This will allow

room to adjust the threaded trun-

nions in the bottom of the manifold.

b. Screw both manifold trunnions (Fig-

ure 72, B) in completely and then back

them out approximately 2-1/2 turns.

Slide the manifold back against the

powerframe (or adapter plate).

!!

CAUTION

Use two people to lift the manifold. The Manifold

is heavy and failure to use two people may cause

serious injury.

Lubrication Fitting

Stuffing Box

Figure 70: Lubrication Line Fittings.

Figure 71: Lift the New Manifold onto the Mounting Studs.

Manifold Mount-

ing Studs

Figure 72: Manifold in Adjustment Position.

A

B

Loading...

Loading...