Operation

Dehydration of a refrigerant system can be obtained by this method because the water present

in the system reacts much as a refrigerant would. By pulling down the pressure in the system

to a point where its saturation temperature is considerably below that of room temperature,

heat will flow from the room through the walls of the system and vaporize the water, allowing

a large percentage of it to be removed by the vacuum pump. The length of time necessary for

the dehydration of a system is dependent on the size or volume of the system, the capacity and

efficiency of the vacuum pump, the room temperature and the quantity of water present in the

system. By the use of the vacuum indicator as suggested, the test tube will be evacuated to the

same pressure as the system, and the distilled water will be maintained at the same saturation

temperature as any free water in the system, and this temperature can be observed on the

thermometer.

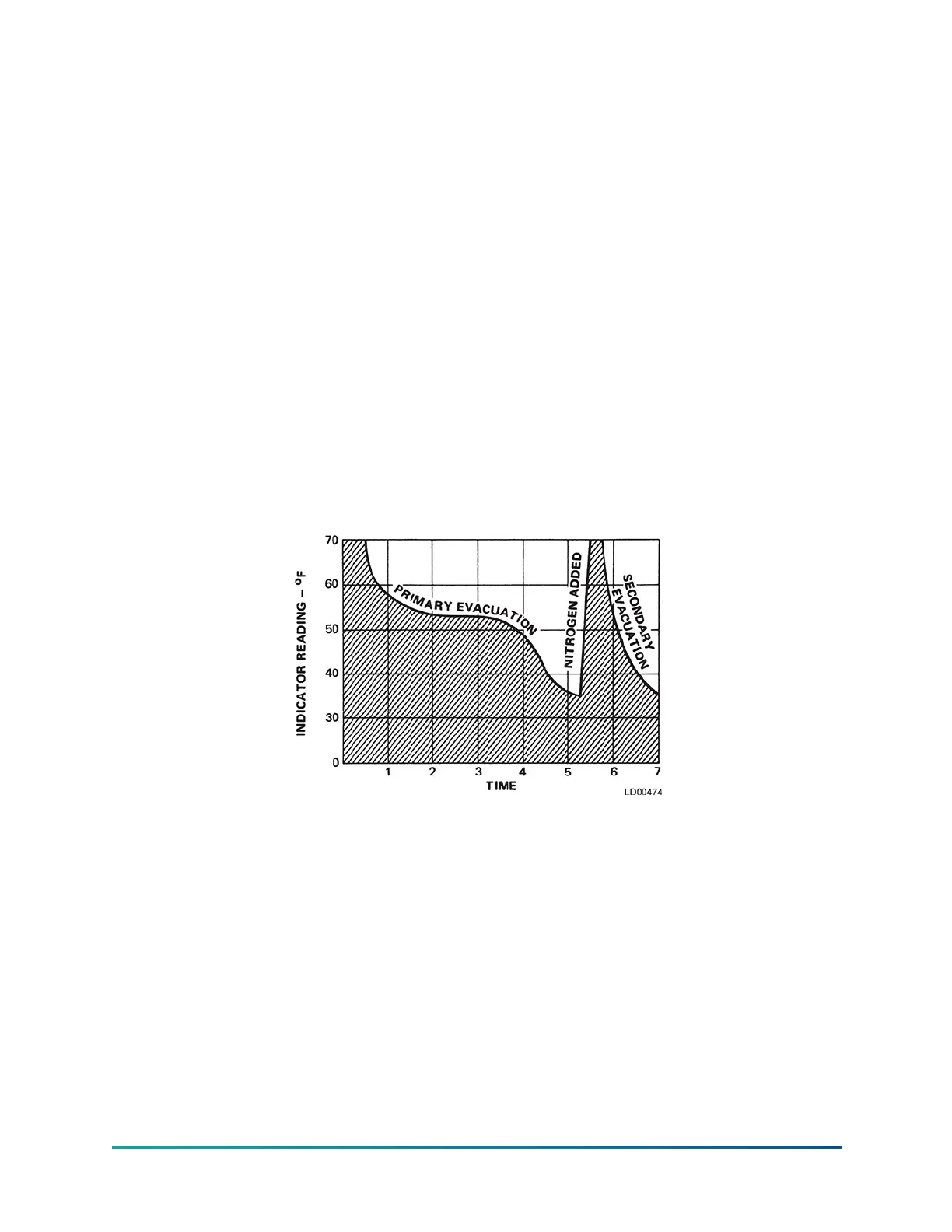

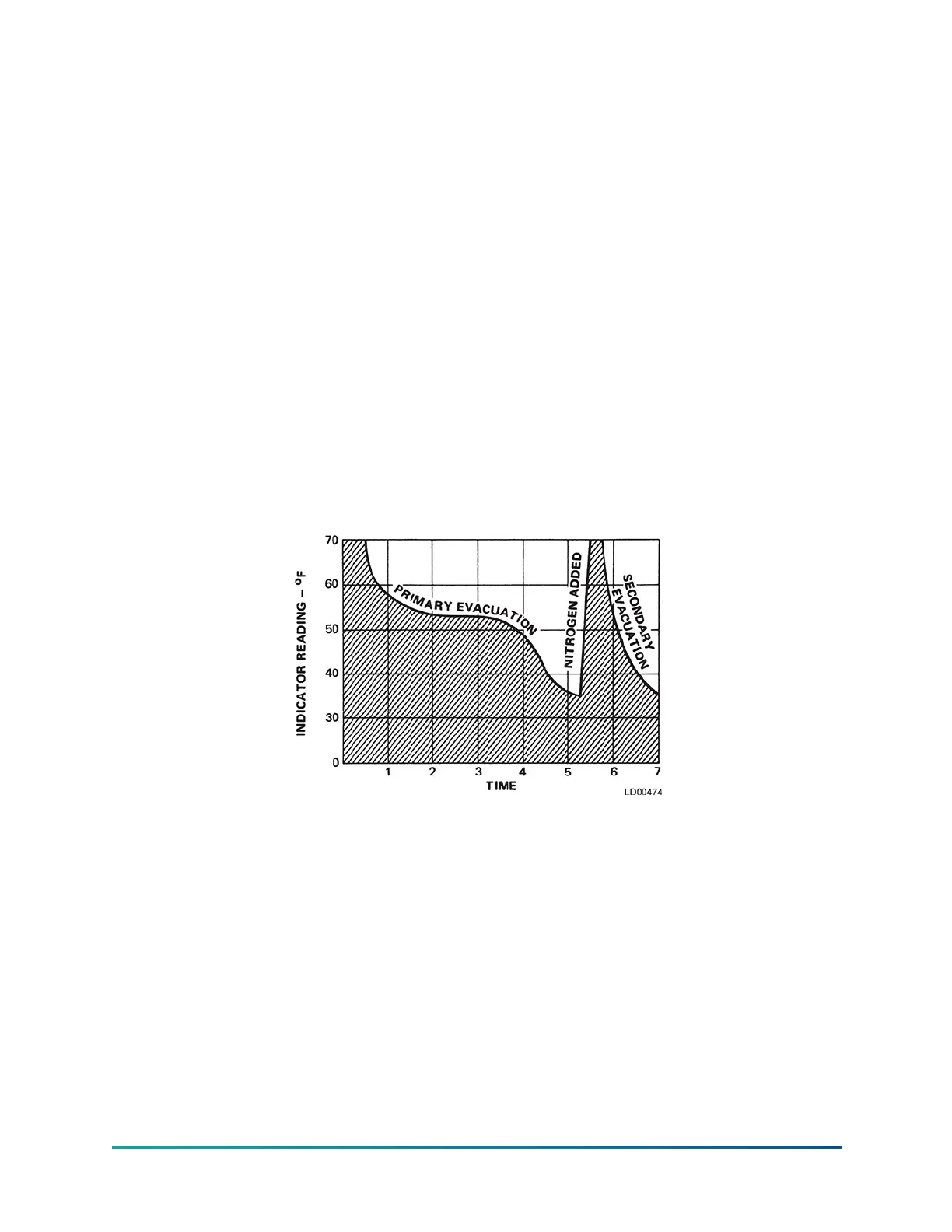

If the system has been pressure tested and found to be tight prior to evacuation, then the

saturation temperature recordings should follow a curve similar to the typical saturation curve

shown as in Figure 56.

The temperature of the water in the test tube will drop as the pressure decreases, until the boiling

point is reached, at which point the temperature will level off and remain at this level until all of

the water in the shell is vaporized. When this final vaporization has taken place the pressure and

temperature will continue to drop until eventually a temperature of 35°F (1.6°C) or a pressure of 5

mm Hg. is reached.

Figure 56: Saturation curve

When this point is reached, practically all of the air has been evacuated from the system, but

there is still a small amount of moisture left. In order to provide a medium for carrying this

residual moisture to the vacuum pump, nitrogen should be introduced into the system to bring

it to atmospheric pressure and the indicator temperature will return to approximately ambient

temperature. Close off the system again, and start the second evacuation.

The relatively small amount of moisture left will be carried out through the vacuum pump and

the temperature or pressure shown by the indicator should drop uniformly until it reaches a

temperature of 35°F (1.6°C) or a pressure of 5 mm Hg.

When the vacuum indicator registers this temperature or pressure, it is a positive sign that the

system is evacuated and dehydrated to the recommended limit. If this level cannot be reached, it

is evident that there is a leak somewhere in the system. Any leaks must be corrected before the

indicator can be pulled down to 35°F (1.6°C) or 5 mm Hg. in the primary evacuation.

YMC

2

Mod B with OptiView

™

Control Center

162

Loading...

Loading...