– 129 –

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

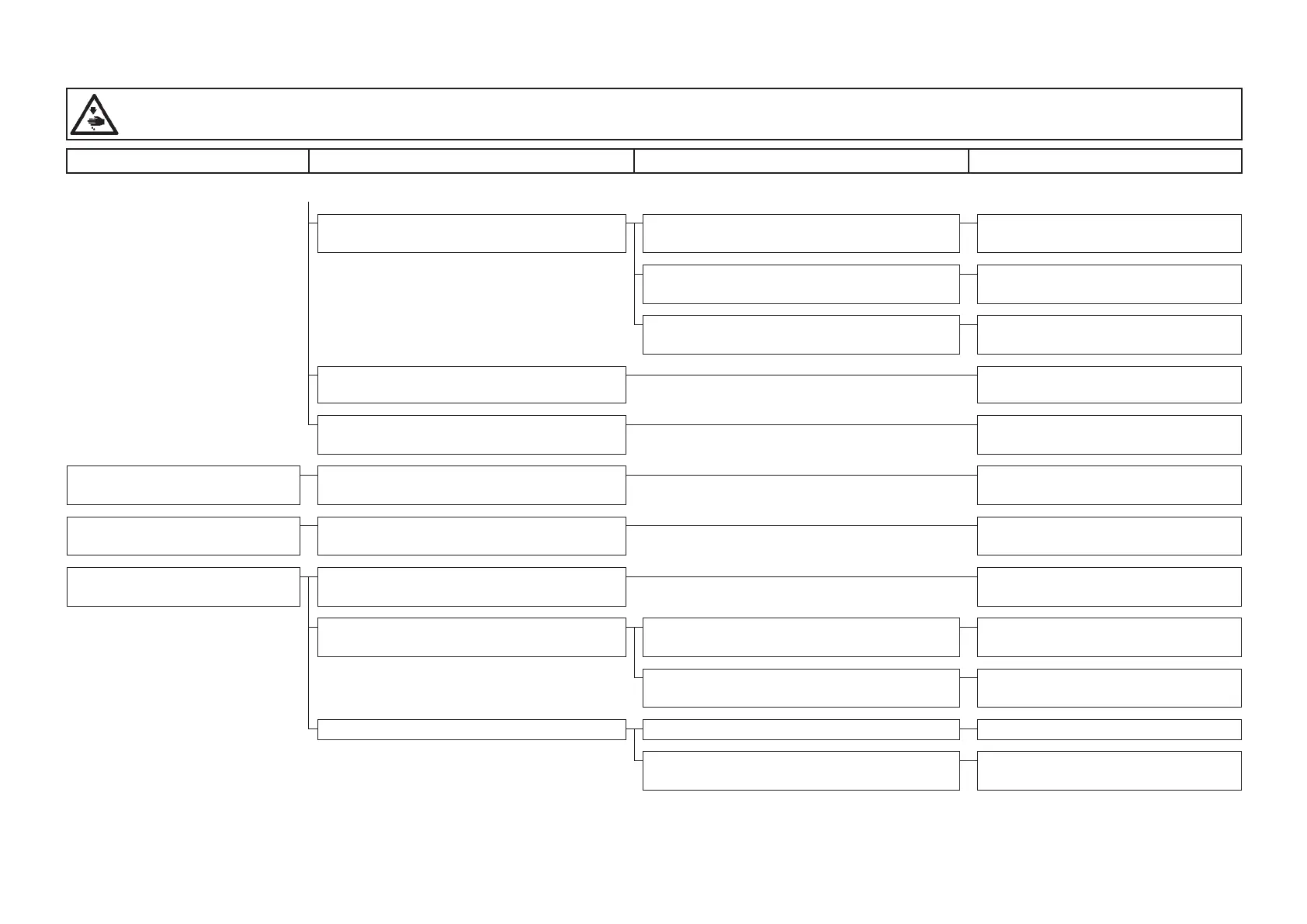

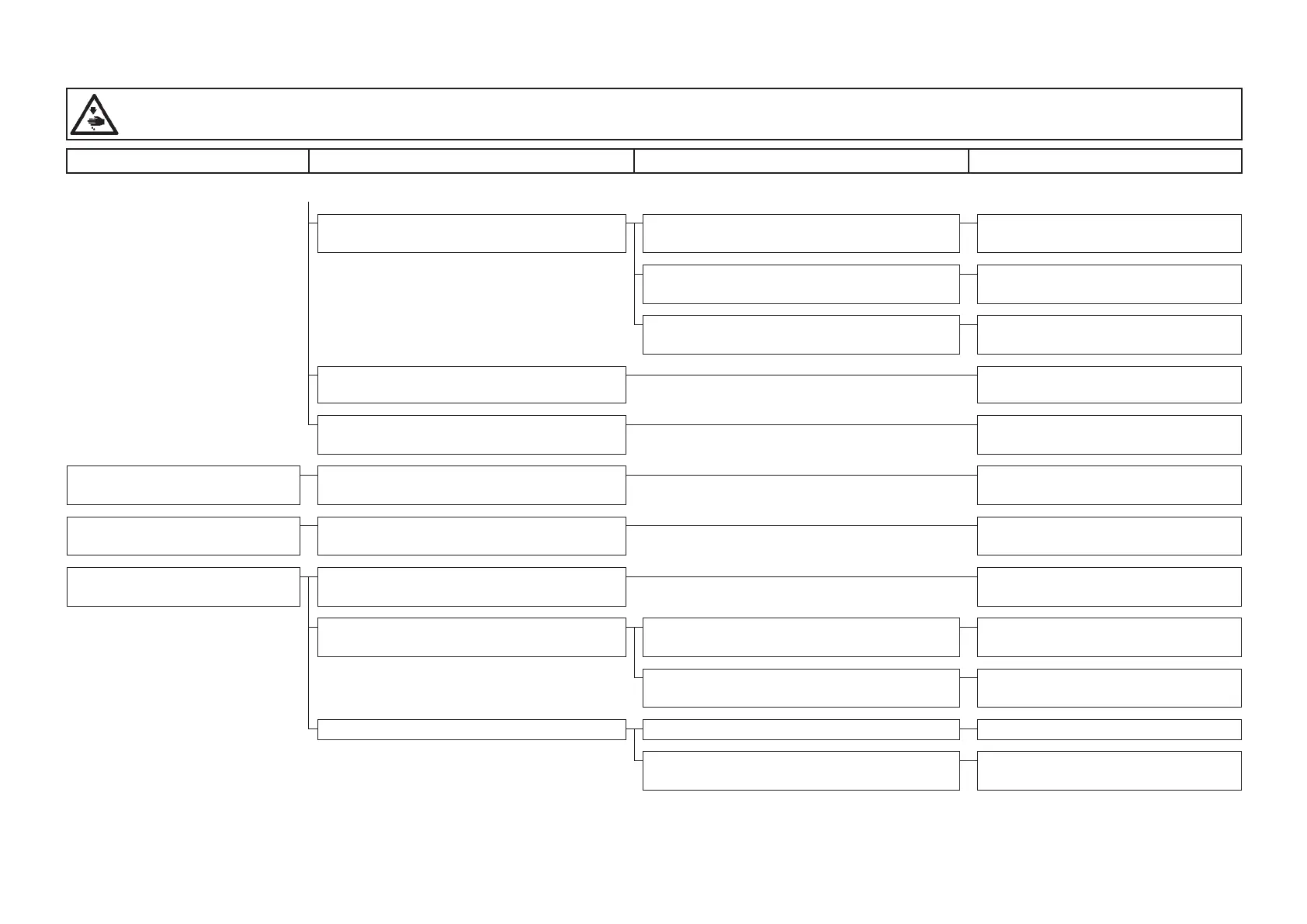

Trouble Cause (1) Cause (2) Check and corrective measures

From the previous page

3-4) Travelling torque in Y-direction is ex-

cessive.

4-A) The pulse motor is pressed against the

Y-feed shaft too strongly.

Adjust backlash of the feed motor

gear.

4-B) Friction is excessive between the Y-feed

arm and the cloth feed support plate.

Install the cloth feed support plate.

4-C) The feed plate or the work clamp foot is

caught by the needle hole guide.

Tighten the setscrew further for the

needle hole guide.

3-5) Inadequate adjustment of the X-sensor

position

Adjust the X-sensor position correctly.

3-6) Inadequate adjustment of the Y-slit

plate

Adjust position of the Y-slit plate cor-

rectly.

4. Sewing machine locked 4-1) Large needle compared with the hole

diameter of the needle hole guide

Replace the needle hole guide.

5. Severe vibration 5-1) Inadequate crank balancer positioning Dene the correct crank balancer

position.

6. Malfunction of vertical move-

ment of work clamp foot

6-1) Looseness of work clamp foot/thread

trimmer cam screw

Dene the work clamp foot/thread

trimmer cam position and x the cam.

6-2) Work clamp foot stepping motor mal-

function

2-A) Defective the work clamp foot stepping

motor.

Replace the work clamp foot stepping

motor.

2-B) The work clamp foot stepping motor is

wrongly connected.

Check the connector connections.

6-3) Defective circuit board 3-A) Circuit board programming aw. Replace the circuit board.

3-B) Connector connections are wrongly

made.

Check the connector connections.

Loading...

Loading...