– 128 –

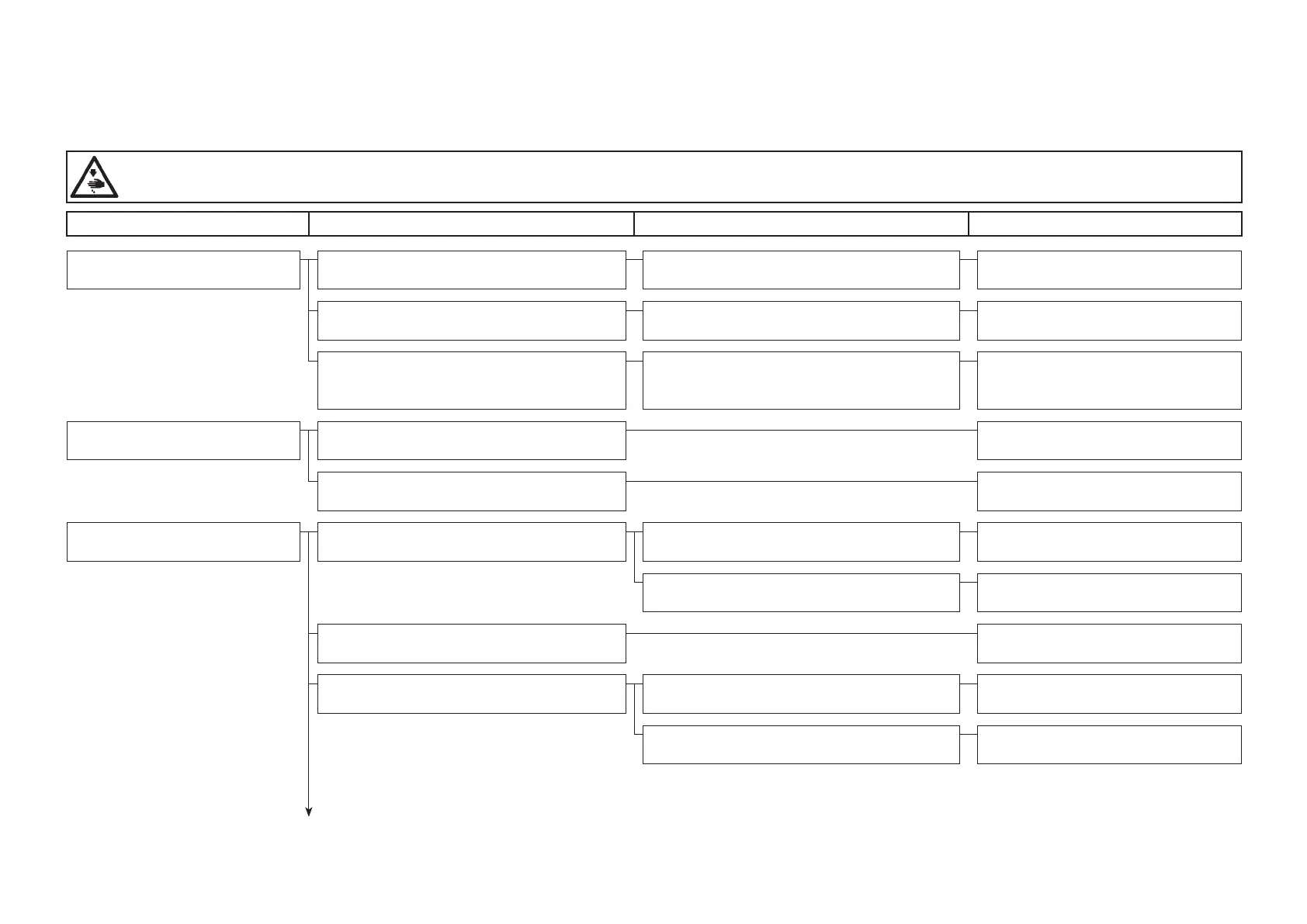

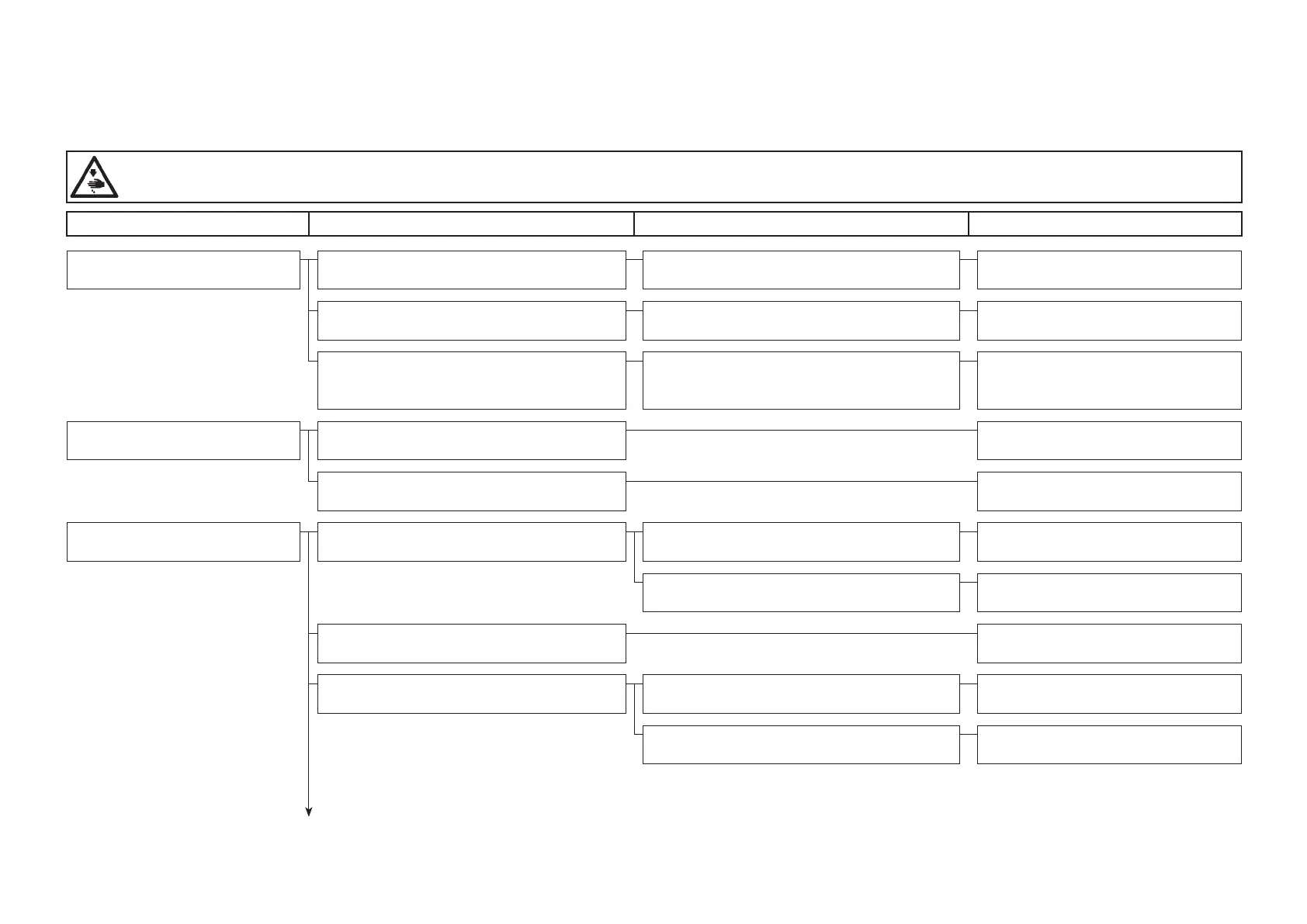

12. Troubles and corrective measures

(1) Mechanical parts

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

Trouble Cause (1) Cause (2) Check and corrective measures

1. Wiper cannot spread a thread. 1-1) Interference between wiper and needle 1-A) Wiper mounting position is inadequate. Adjust the wiper position.

1-2) Displacement of front-rear wiper posi-

tion

2-A) Wiper mounting position is inadequate. Adjust the wiper position.

1-3) Thread holding before wiper action 3-A) The right left wiper mounting position is

inadequate (insufcient distance to the

needle).

Adjust the wiper position.

2. Abnormal noise 2-1) Backlash between the oscillator and

the shuttle driver shaft is large.

Check oscillator gear positioning and

adjust the lower shaft gear backlash.

2-2) Too much clearance between inner

hook and shuttle driver

Adjust the clearance between inner

hook and shuttle driver

3. Deformation in sewn patterns 3-1) Too much backlash in the Y-feed gear 1-A) Backlash is too much in the Y-feed arm

and the motor base.

Adjust backlash of motor base.

1-B) Backlash is too much in the Y-feed pulse

motor and the motor base.

Adjust backlash of Y-feed pulse mo-

tor.

3-2) Too much backlash in the X-feed gear Adjust backlash of the X-feed gear.

3-3) Travelling torque in X-direction is ex-

cessive.

3-A) The motor is pressed against the X-feed

arm too strongly.

Adjust backlash of the motor.

3-B) The feed plate or the work clamp foot is

caught by the needle hole guide.

Tighten the setscrew further for the

needle hole guide.

To the next page

Loading...

Loading...