– 52 –

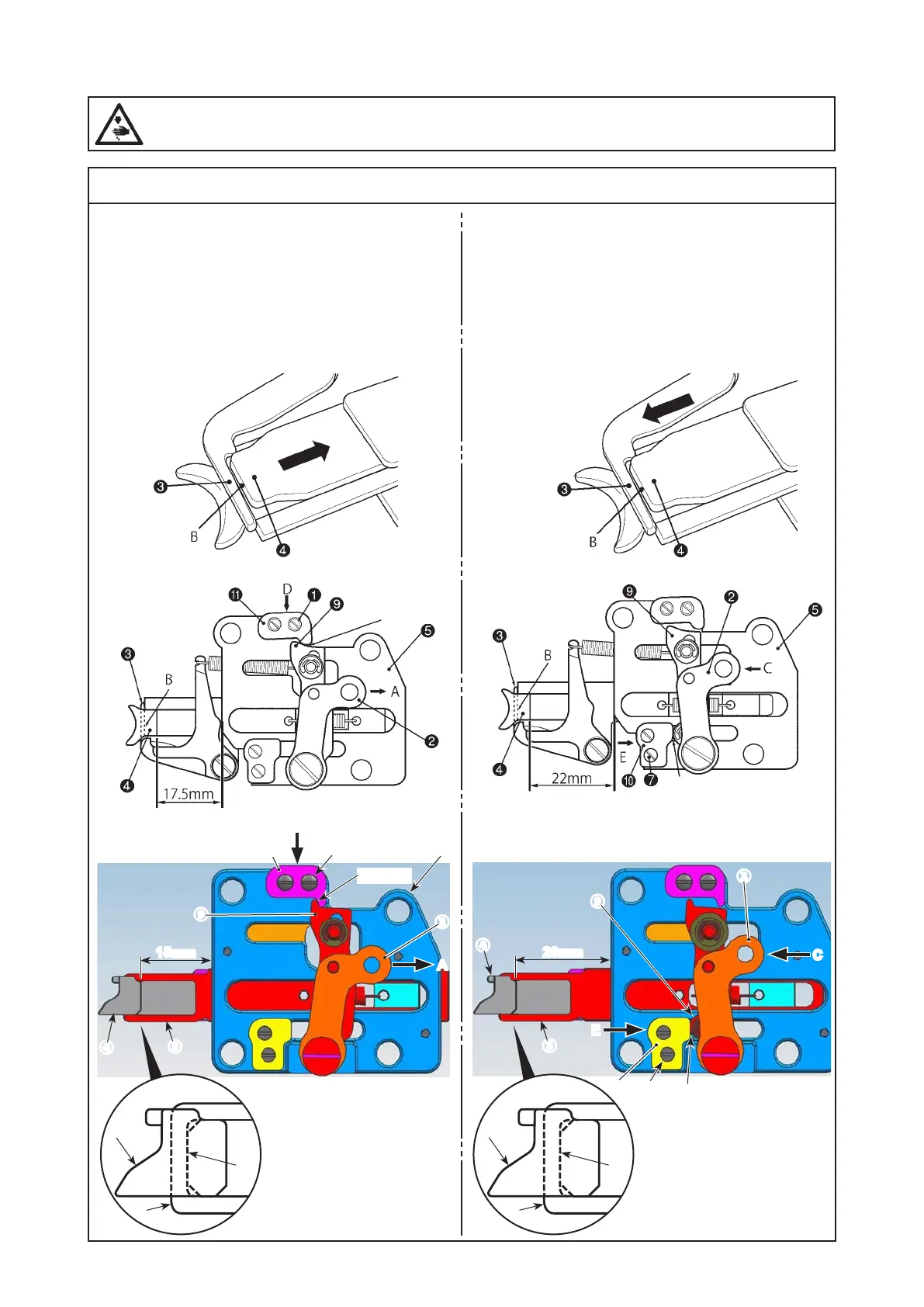

(37) Adjustment of the needle thread clamp notch

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Standard adjustment

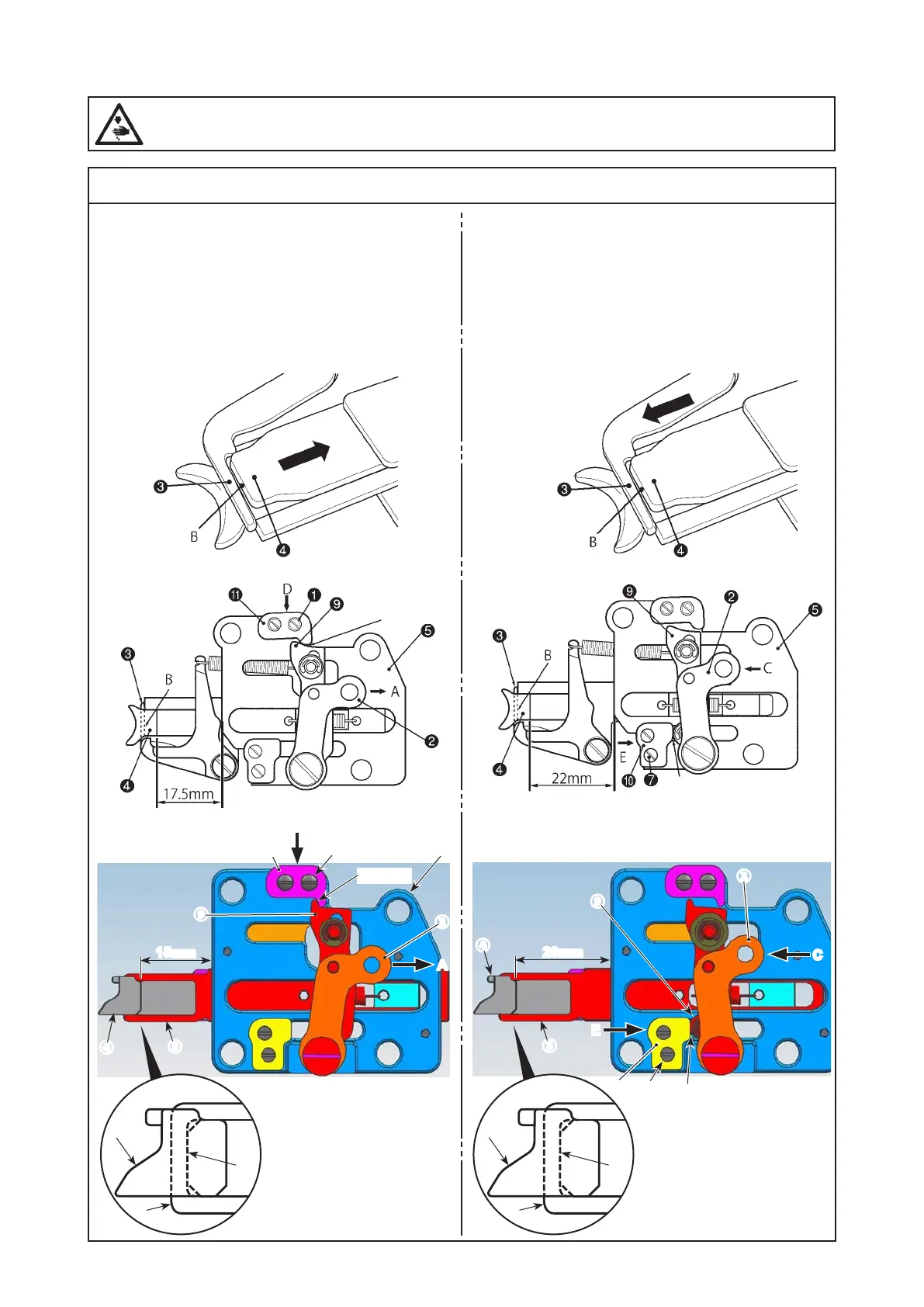

2. Needle thread clamp notch F position

1)

When the needle thread clamp link (asm.)

❷

is

pushed in Direction C and Part B of the needle

thread clamp support plate (asm.)

❸

and the

needle thread clamp

❹

begins to open, the

distance between the needle thread clamp

❹

and the needle thread clamp base

❺

becomes

22 mm (common to S and H type) (LK-1900BB,

1903BB, 1900BNB, 1903BNB : 20mm).

1. Needle thread clamp notch R position

1)

When the needle thread clamp link (asm.)

❷

is

pushed in Direction A and Part B of the needle

thread clamp support plate (asm.)

❸

and the

needle thread clamp

❹

begins to open, the dis-

tance between the needle thread clamp

❹

and

the needle thread clamp base

❺

becomes 17.5

mm (common to S and H type) (LK-1900BB,

1903BB, 1900BNB, 1903BNB : 15mm).

[LK-1900BB, 1903BB, 1900BNB, 1903BNB (Short tail application] [LK-1900BB, 1903BB, 1900BNB, 1903BNB (Short tail application]

❸

❹

20mm

Contact

❼

❾

❷

E

C

❸

❹

15mm

Contact

❺ ❶

❾

❷

D

A

❹

❸

B

❹

❸

B

Contact

S and H : specications in common S and H : specications in common

Contact

Loading...

Loading...