– 131 –

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

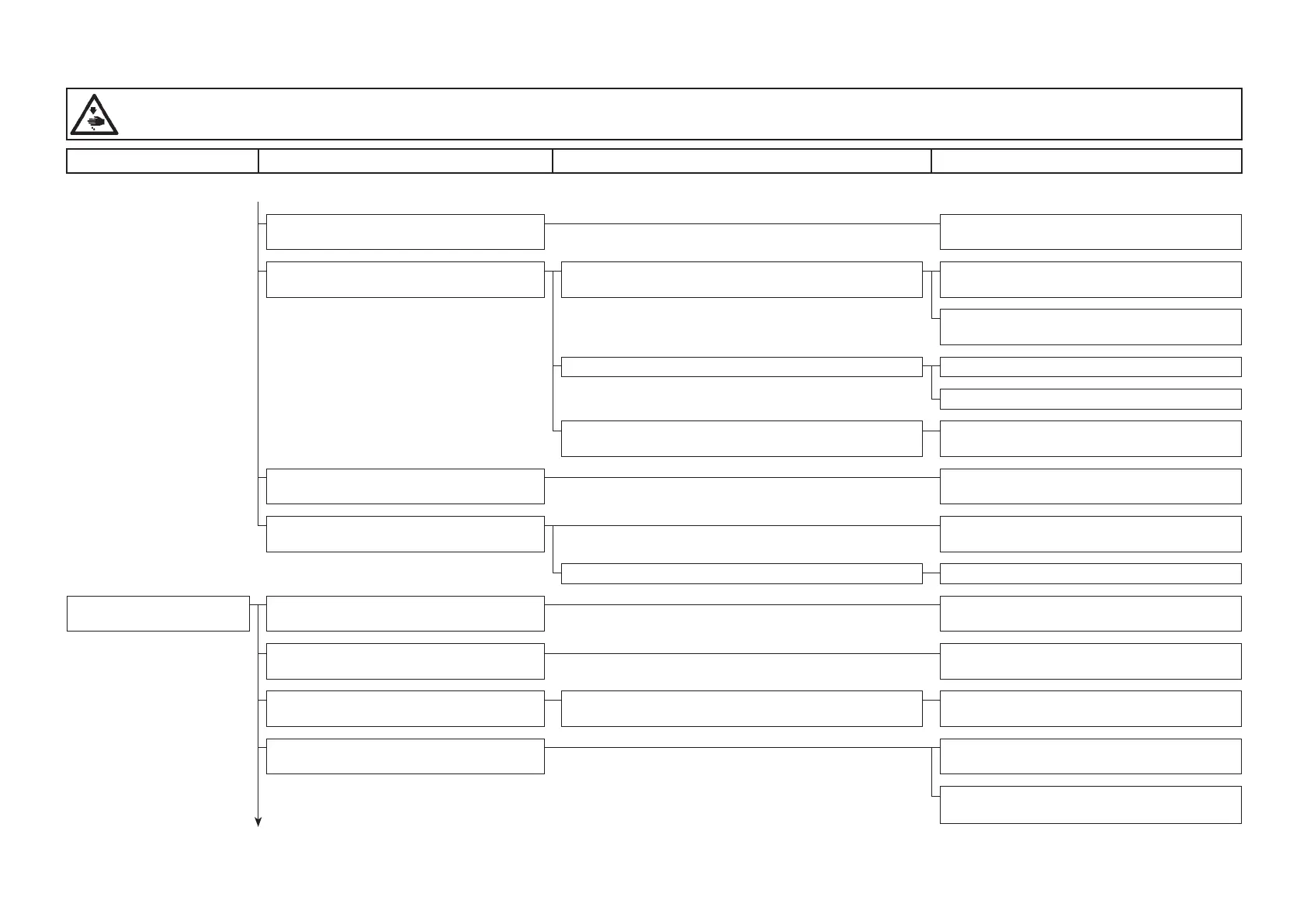

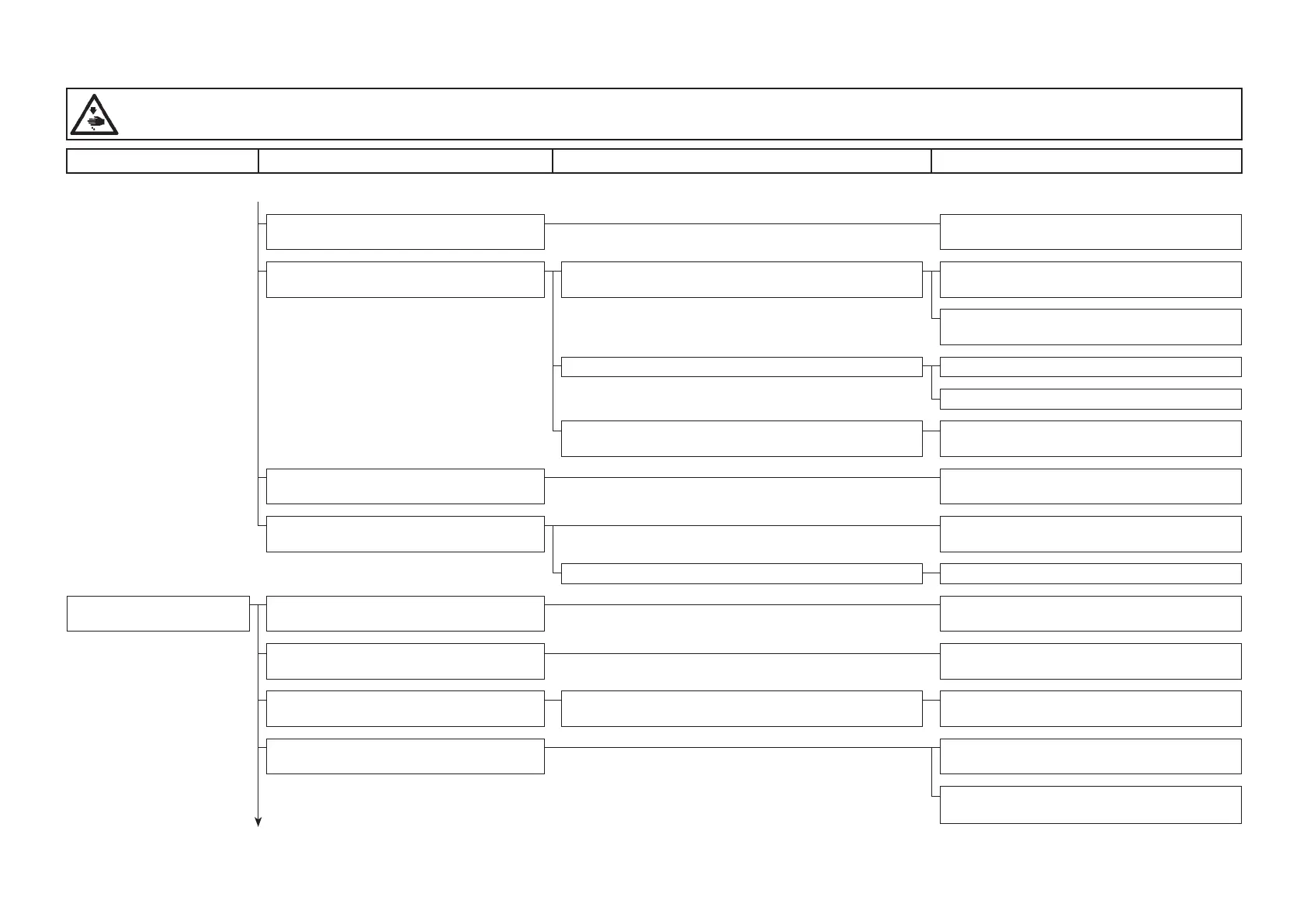

Trouble Cause (1) Cause (2) Check and corrective measures

From the previous page

1-4) Material to be sewn is not properly

stretched.

Remove the slack of the material to be sewn.

1-5) Unstable needle thread clamp 5-A) Thread tends to be extended or sliding efciency is

worse.

Increase the number of stitches of needle

thread clamp to 3 to 4 stitches.

Lower the speed of the 1st stitch. (600 to 1,000

sti/min)

5-B) Pitch of 1st stitch is too small. Lower the needle thread tension of 1st stitch.

Increase the pitch of 1st stitch.

5-C)

Needle thread that is cut with the bird's nest knife has

not been sucked. (LK-1900BB/BNB, 1903BB/BNB)

Clean up the needle thread clamp section.

1-6) Threading the needle bar thread guide

is wrong.

Refer to the item “Threading the needle bar

thread Guide”.

1-7) Bobbin runs idle and the bobbin

thread is drawn out.

Use a stronger idling prevention spring.

7-A) Initial positioning of the moving knife is inadequate. Adjust the initial position of the moving knife.

2. Needle breakage 2-1) Inadequate clearance between the

shuttle driver and the needle

Adjust the clearance between needle and shut-

tle driver.

2-2) Inadequate clearance between the

needle and the inner hook

Adjust the clearance between the needle and

the inner hook.

2-3) Feed timing is defective. 3-A) Feed timing is slow in regard to the work pressure. Change the feed timing by the use of the mem-

ory switch.

2-4) Needle comes in contact with the

moving knife.

Adjust the moving knife position.

Adjust the work clamp foot (feed bracket) posi-

tion.

To the next page

Loading...

Loading...