– 137 –

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

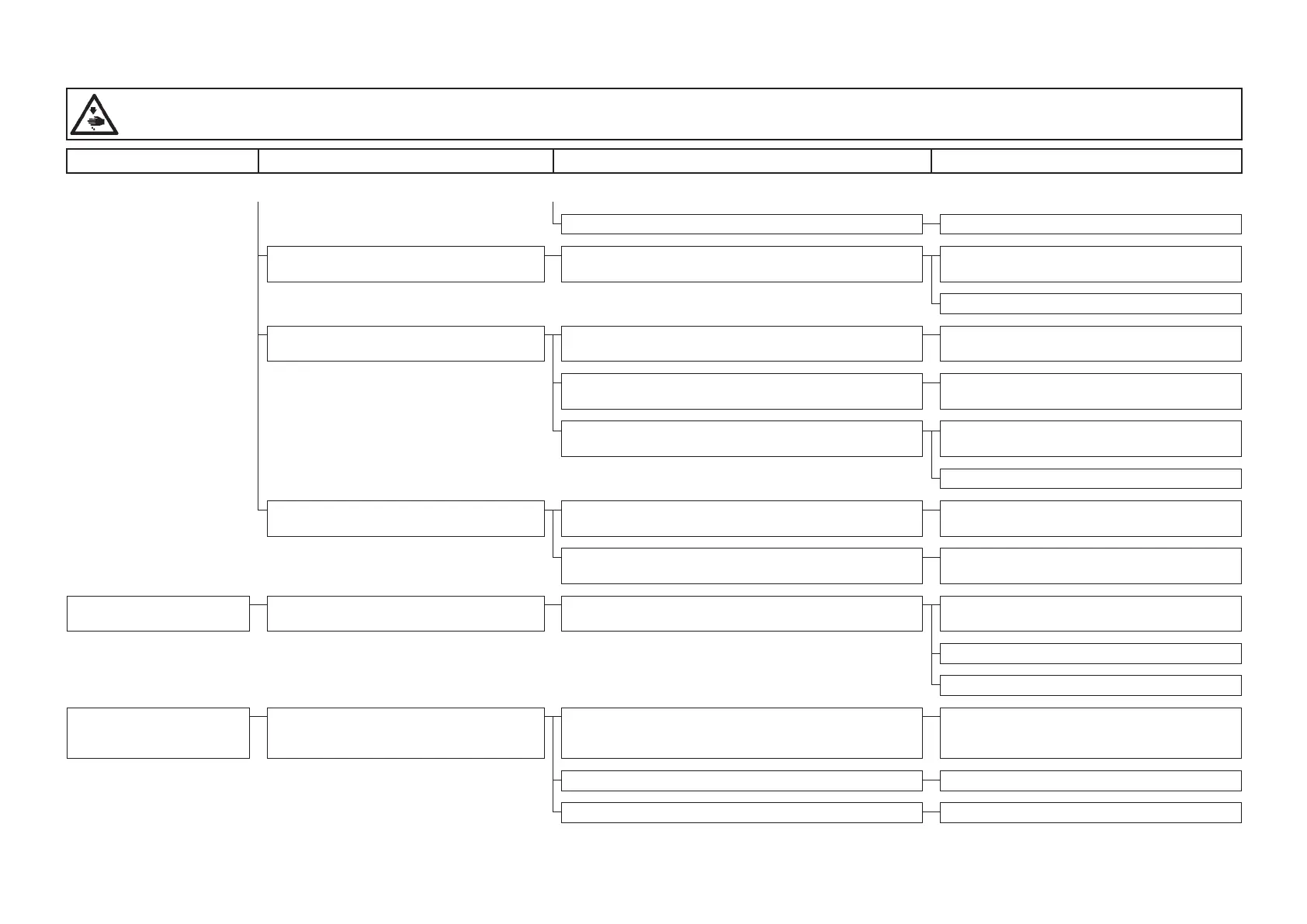

Trouble Cause (1) Cause (2) Check and corrective measures

From the previous page From the previous page

2-C) Loop of the needle thread falls down. Move the thread guide A to the left.

8-3) Thread oating occurs at the sewing

start.

3-A)

Penetration resistance of the thread against the

cloth is too small.

Use a thinner needle. (Lower the number of

needle to be used.)

Needle thread clamp ON.

8-4) Stitch skipping due to the heat 4-A) Sewing speed is too fast. Change the maximum speed (electrical compo-

nents.)

4-B) Needle is too thin. Use a thicker needle. (Raise the number of nee-

dle to be used.)

4-C) Loop of the needle thread falls down. Attach the needle with the long groove orienting

slightly to the right (approximately 20°).

Use a needle cooler.

8-5)

Uneven stitch tightness due to the

stretch of thread

5-A) Sewing speed is too fast. Reduce the speed by means of the speed vari-

able resistor.

5-B) Tension of the thread tension No. 2 (asm.) is exces-

sive.

Decrease the tension of tension controller No. 2.

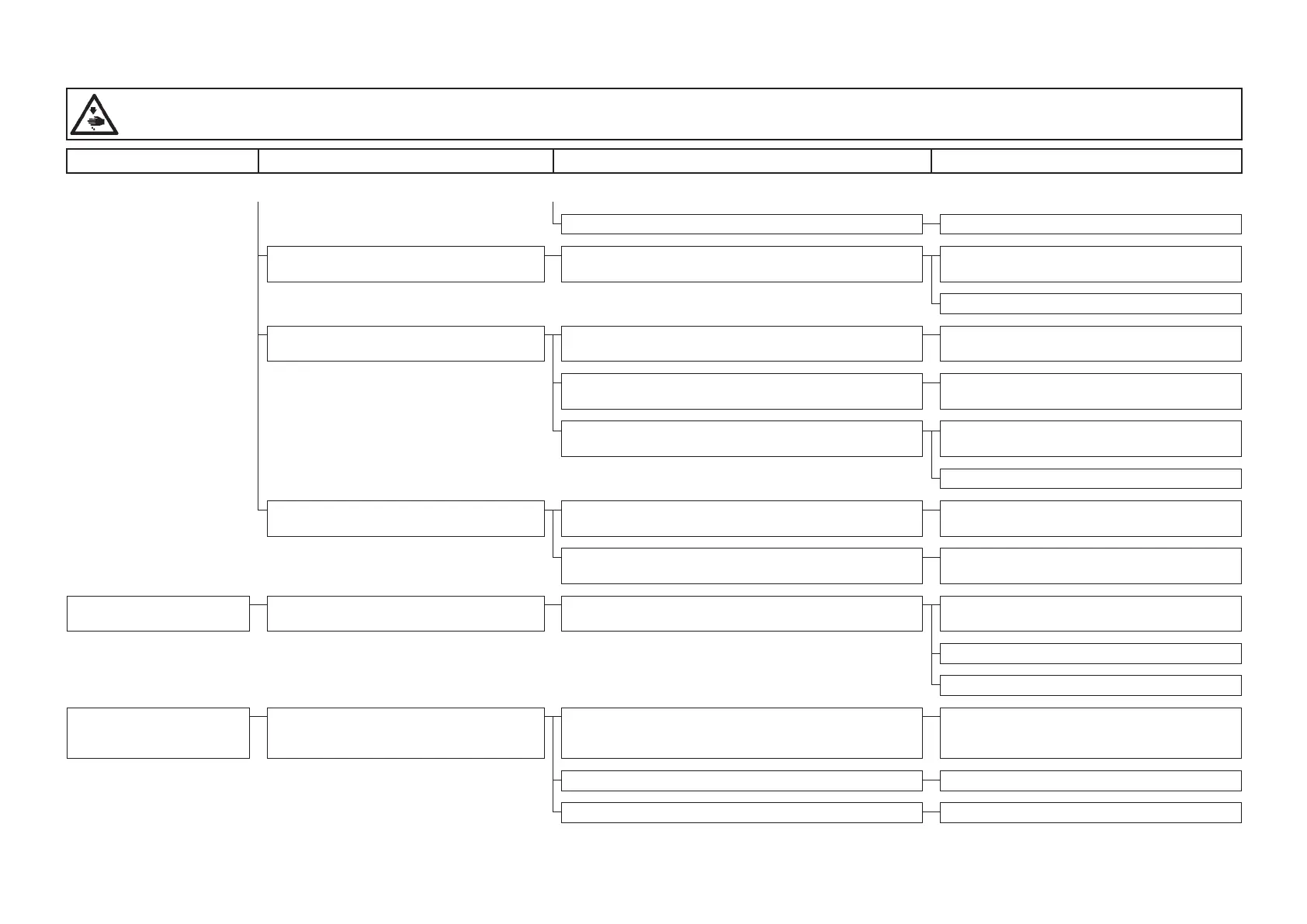

9. Thread chips generated

in the shuttle

9-1) Long needle thread at the beginning

of stitches

1-A) The thread trimmer is used for cutting. Needle thread clamp OFF

Adjust the needle thread length to 32 to 36 mm.

Increase the sewing length to more than 10 mm.

10. Roll-in malfunction of

remaining thread at

underside material.

10-1

) Protrusion of needle thread 1-A) Material does not keep close contact with the throat

plate.

Change the feed plate.

1-B) Stitch size is short.

Increase the sewing size to more than 10 mm.

1-C) The needle thread is long.

Adjust the needle thread length to 32 to 36 mm.

Loading...

Loading...