– 15 –

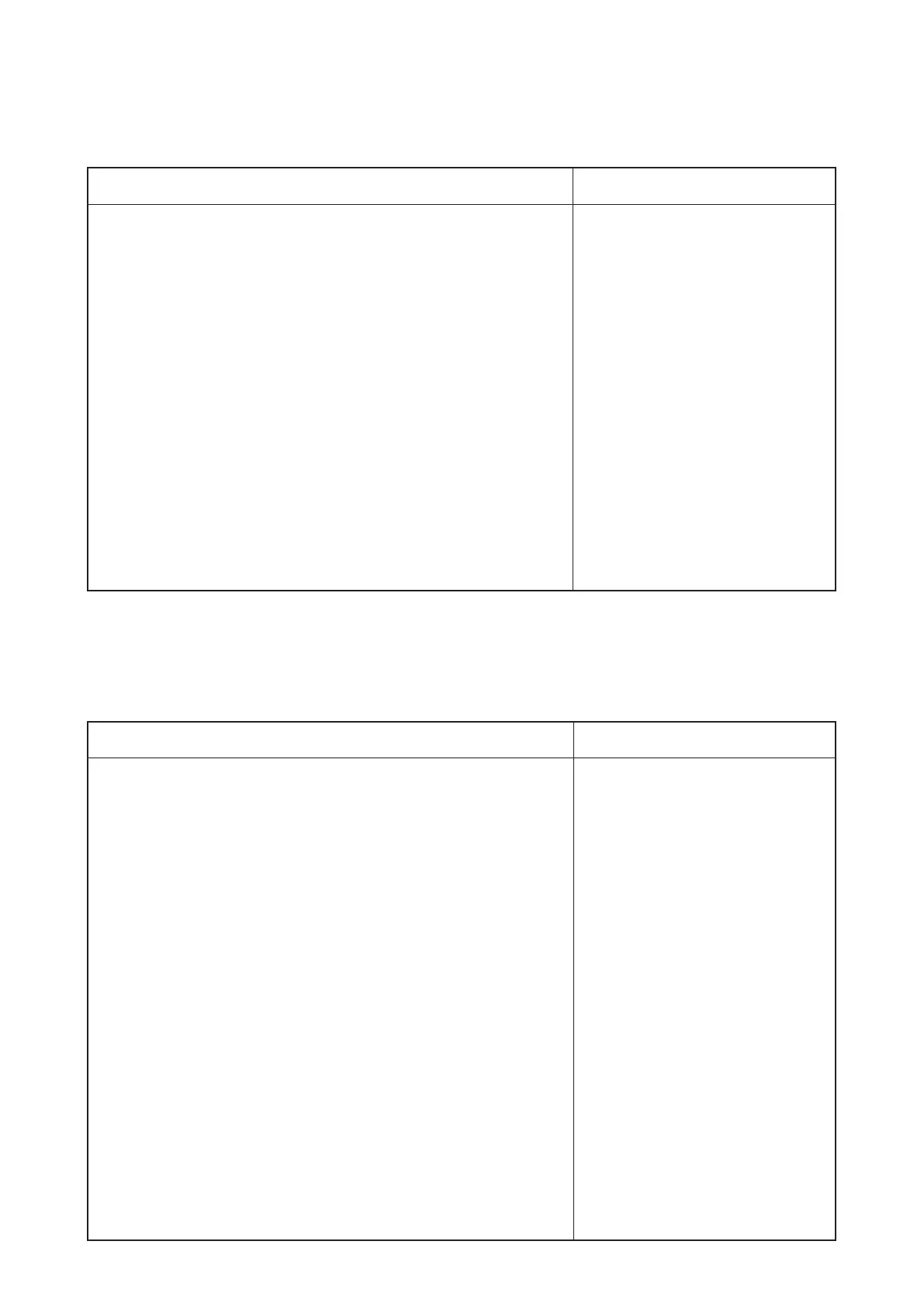

Adjustment procedures

Results of Improper adjustment

If the main shaft eccentric cam

❽

isnotxed,thisadjustment

shouldbecarriedoutafterdeningitspositionandxingit.

1. Loosen the two setscrews

❼

of the crank balancer

❻

.

2. Using the two setscrews

❷

, remove the crank rod cover

❶

.

3.Turnthemainshaftinthedirectionofforwardrotation

A

so that

the needle bar

❸

lowers and the clearance between the needle

bar connecting

❹

and the needle bar bushing, lower

❺

is 5.7 mm

(LK-1903B,1903BN:4.6mm).

4. In the state that the two setscrews

❼

of the crank balancer

❻

as-

sumethehorizontalconditionandtheyaremovedinthedirection

of the arrow mark

B

, keep the close contact with the main shaft

eccentric cam

❽

and tighten the two setscrews

❼

. When tight-

ening these two setscrews

❼

, the screws should be tightened

reciprocally.

o

Iftheangleforxingthecrank

balancer

❻

isinadequate,vibra-

tion of sewing machine operation

willbeintensied.

o

If the sewing machine is used for

alongtimewhilethexingposi-

tionisinadequate,theoperation-

al life of the main shaft bearing

maybeshortened.

o

If the crank balancer

❻

is not

moved in the direction of the

arrow mark

B

,theremaybe

interference with the sewing

machine frame.

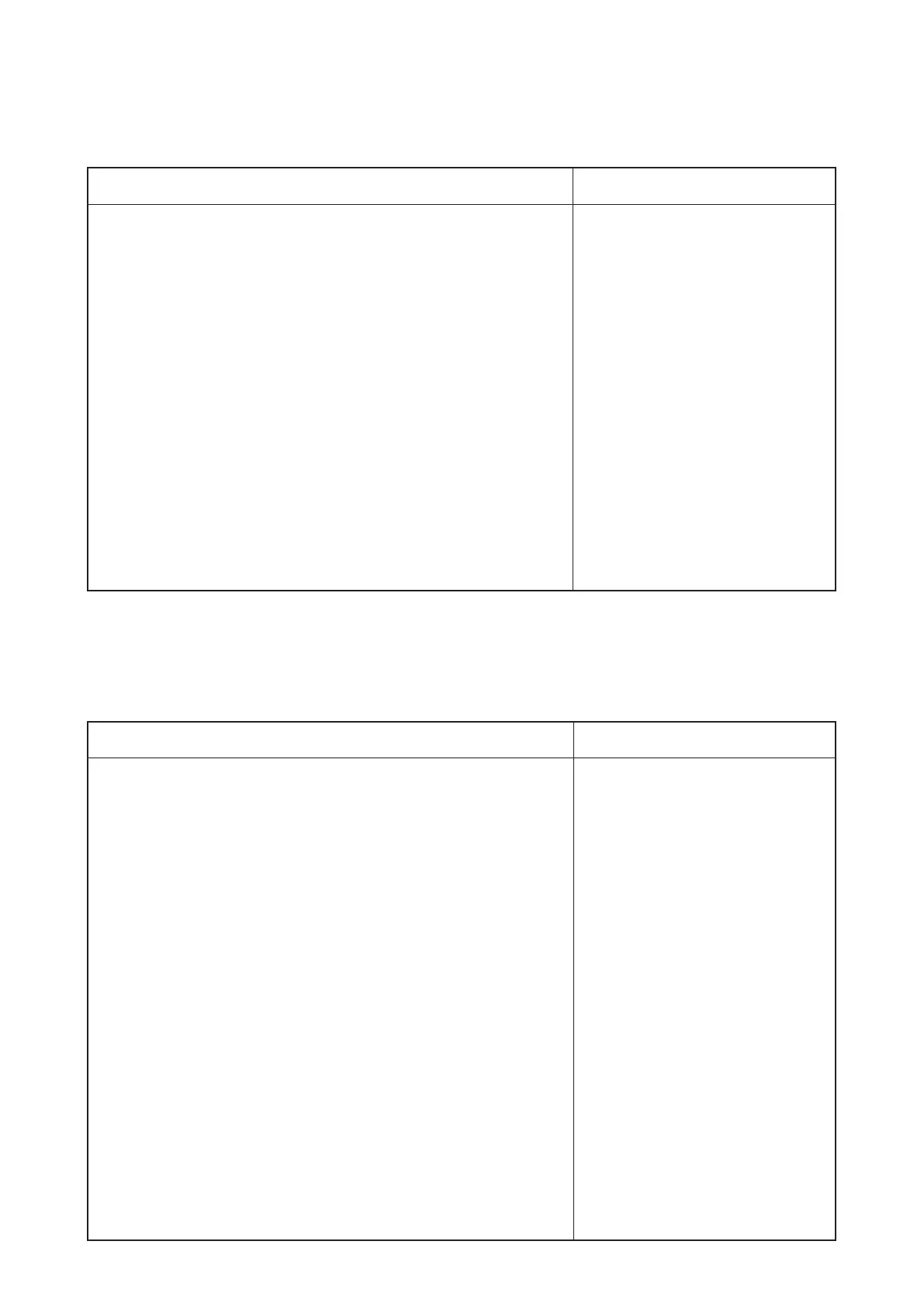

Adjustment procedures

Results of Improper adjustment

1. Lower shaft backlash

1) Loosen the two setscrews

❶

.

2)Turnthelowershaftrearmetal

❷

in the direction of the arrow

andadjustthebacklash,keepingthemetaltocontactclosely

with Face A.

Size of backlash is 0.1 mm at the tip of the driver

❺

.Theshaft

isrequiredtorotatesmoothly.

3)Tightenthetwosetscrews

❶

.

(Caution) When eliminate the backlash, the direction of rotation

should always be kept in the direction of the arrow.

2. Lower shaft connection/disconnection

1) Loosen the two setscrews

❼

.

2)Thelowershaft

❻

can be taken out if it is pulled in the direc-

tion

C

of the arrow.

3) When mounting the lower shaft

❻

, insert it in the lower shaft

rear metal

❷

and the lower shaft gear

❸

.Applyoneofthe

setscrews

❼

totheatsection

❽

of the lower shaft

❻

and

tightenitapproximatelyinthecenter.Tightentheremaining

setscrew

❼

.

* Connection and disconnection of the lower shaft

❻

becomeeasy

if the above-mentioned backlash has been relieved in advance. In

thiscase,backlashadjustmentmustbedoneafterthelowershaft

❻

has been installed.

o

Ifthebacklashisexcessive,the

hook noise will be increased.

o

If backlash is too small, the low-

er shaft gear

❸

or the oscillator

❹

will give rise to frictional wear.

In addition, this can be a cause

of crank rod lock-up.

o

If the front or rear position of

the lower shaft rear metal

❷

is

displaced at the time of backlash

adjustment,thiscanalsobea

cause of the lock-up of oscillator

❹

or the crank rod.

Loading...

Loading...